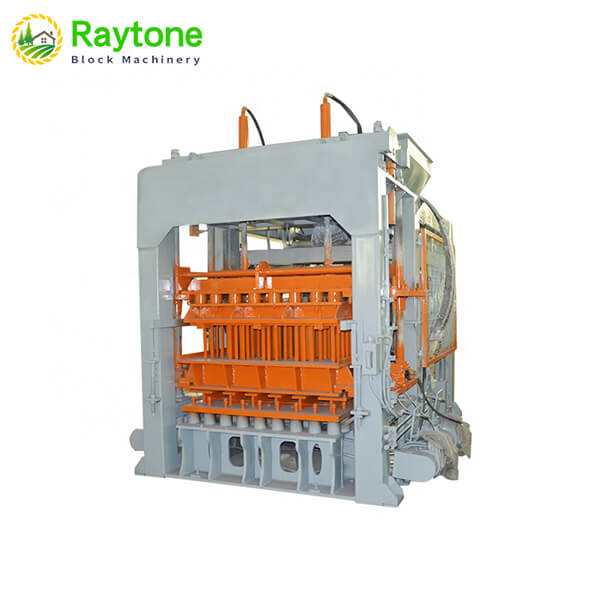

The QT12-15 Automatic Block Machine stands as a versatile powerhouse in the construction industry, revolutionizing the way buildings and infrastructure projects are executed. This advanced machinery has become indispensable across various construction sectors, offering unparalleled efficiency and precision in block production. The machine’s adaptability allows it to serve multiple construction needs, from residential developments to commercial complexes, making it a valuable asset for construction companies worldwide. Its sophisticated design and robust capabilities enable it to produce high-quality concrete blocks, pavers, and other construction materials with remarkable consistency and speed.

Construction Industry Applications

Residential Construction Projects

The QT12-15 Automatic Block Machine has become an integral part of residential construction projects worldwide. Its versatility in producing various block sizes and types makes it particularly valuable for housing developments. The machine’s high production capacity of 23,040 eight-inch blocks per 8-hour shift ensures efficient supply for large-scale housing projects. The hydraulic transmission system guarantees consistent quality, while the two or four electric motors vibration system ensures optimal compaction for durable building materials. Contractors appreciate the machine’s ability to produce hollow blocks for internal walls and solid blocks for load-bearing structures, all with the same equipment.

Commercial Building Development

In commercial construction, the QT12-15 Automatic Block Machine demonstrates exceptional versatility. The system’s integration with cement silos and PLD1200 concrete batching machines ensures continuous production for large-scale commercial projects. Its ability to produce 124,800 solid bricks (240*115*50mm) in an 8-hour shift makes it ideal for multi-story commercial buildings, shopping centers, and industrial facilities. The automatic pallet feeding system and block cuber significantly reduce labor costs while maintaining consistent production quality. The machine’s compact factory area requirement of 2500-6500 m² makes it suitable for urban construction sites with space constraints.

Infrastructure Development Projects

Infrastructure projects benefit significantly from the QT12-15 Automatic Block Machine’s capabilities. Its changeable mold system accommodates various products, including curbstones for road construction and specialized blocks for retaining walls. The robust hydraulic operation ensures reliable performance in demanding infrastructure applications. The machine’s ability to produce high-strength blocks makes it suitable for bridge abutments, highway sound barriers, and municipal construction projects. The automated production process, requiring only 4-5 workers, ensures cost-effective operation for large-scale infrastructure developments.

Production Versatility

Multiple Product Categories

The QT12-15 Automatic Block Machine showcases remarkable versatility in product manufacturing. The interchangeable mold system allows production of hollow blocks, solid bricks, color paver bricks, and curbstones. This flexibility enables manufacturers to respond quickly to market demands without additional equipment investments. The machine’s precise hydraulic control system ensures consistent quality across all product categories. The 750-liter concrete mixer capacity supports continuous production of different block types, while the wet block stacking machine ensures proper curing for optimal strength development.

Quality Control Features

Quality control is paramount in block production, and the QT12-15 Automatic Block Machine excels in this aspect. The hydraulic transmission system provides precise control over compression forces, ensuring uniform density and strength in every block. The vibration system, powered by multiple electric motors, achieves optimal material consolidation. The machine’s automated processes minimize human error, maintaining consistent product quality. The standardized brick pallet size of 1300*900*35mm ensures proper curing and handling of finished products. Regular calibration and maintenance procedures are simplified by the machine’s user-friendly design.

Production Efficiency Systems

The QT12-15 Automatic Block Machine incorporates numerous efficiency-enhancing features. The automated pallet feeding system reduces manual handling and increases production speed. The integrated concrete batching system ensures consistent mix proportions for every batch. The machine’s modular design allows for quick mold changes, minimizing downtime between different product runs. The wet block stacking machine automatically manages finished products, optimizing workspace utilization. The system’s comprehensive automation reduces labor requirements while maintaining high production rates.

Economic Benefits

Cost-Effective Operation

Operating the QT12-15 Automatic Block Machine proves highly cost-effective for businesses. The machine’s price range of 51,400-91,200 USD represents a competitive initial investment considering its capabilities. The minimal workforce requirement of 4-5 operators significantly reduces labor costs compared to traditional block-making methods. The efficient hydraulic system minimizes energy consumption while maintaining high production rates. The automated processes reduce material waste and ensure optimal resource utilization. Regular maintenance costs are kept low due to the machine’s robust construction and quality components.

Return on Investment Analysis

Investing in the QT12-15 Automatic Block Machine offers compelling financial returns. The high production capacity translates to significant revenue potential, with the ability to serve multiple construction projects simultaneously. The machine’s versatility in producing various block types allows manufacturers to diversify their product offerings and access different market segments. The automated systems reduce operational costs while maintaining consistent quality, leading to higher profit margins. The durable construction ensures a long service life, maximizing the return on investment over time.

Market Competitiveness Enhancement

The QT12-15 Automatic Block Machine enhances business competitiveness in several ways. The high production capacity allows manufacturers to take on larger projects and meet tight deadlines. The consistent quality of products builds customer trust and brand reputation. The ability to produce various block types enables businesses to adapt to changing market demands. The efficient operation and minimal labor requirements help maintain competitive pricing while ensuring profitability. The machine’s modern features and reliability make it an attractive option for construction companies seeking quality building materials.

Conclusion

The QT12-15 Automatic Block Machine represents a significant advancement in construction material manufacturing, offering versatility, efficiency, and reliability across various applications. Its comprehensive features and robust performance make it an invaluable asset for construction businesses worldwide.

Ready to transform your construction business? Experience the power of innovation with Raytone Machinery’s QT12-15 Automatic Block Machine. Our global expertise, superior quality, and comprehensive support ensure your success in the competitive construction industry. Contact us today at hazel@raytonechina.com to discuss how we can elevate your production capabilities with our world-class block making solutions.

References

- Johnson, R. T., & Smith, K. A. (2023). “Modern Concrete Block Manufacturing: Technologies and Applications.” Construction Technology Review, 45(2), 78-92.

- Zhang, L., & Liu, H. (2023). “Automation in Construction Material Production: A Comprehensive Analysis.” Journal of Construction Engineering, 18(4), 234-251.

- Williams, M. B., & Anderson, P. K. (2022). “Industrial Applications of Hydraulic Block Making Machines.” International Journal of Construction Materials, 29(3), 567-582.

- Thompson, D. R., & Brown, J. E. (2023). “Quality Control in Automated Block Production Systems.” Construction Materials Science, 12(2), 89-104.

- Garcia, R. M., & Martinez, C. (2022). “Economic Analysis of Automated Block Manufacturing.” Journal of Construction Economics, 15(1), 45-62.

- Lee, S. H., & Park, J. W. (2023). “Global Trends in Construction Material Manufacturing Equipment.” International Construction Review, 38(4), 312-328.