The QT12-15 Automatic Block Machine stands as a pinnacle of efficiency in concrete block production, offering remarkable output capabilities that set new industry standards. This advanced machinery can produce an impressive 23,040 pieces of 8-inch blocks or 124,800 pieces of solid bricks (240*115*50mm) in just 8 hours of operation. Such high production capacity makes it an ideal choice for medium to large-scale construction projects and commercial block manufacturing facilities, delivering consistent quality while maintaining optimal operational efficiency.

Technical Specifications and Production Output

Advanced Hydraulic System Integration

The QT12-15 Automatic Block Machine utilizes a state-of-the-art hydraulic transmission system that ensures precise control and consistent production quality. The system’s robust design incorporates two to four electric motors for vibration, creating optimal compaction conditions for each block produced. This advanced hydraulic operation allows for smooth, continuous production while minimizing maintenance requirements and reducing operational costs. The machine’s sophisticated control system enables operators to fine-tune production parameters, ensuring each block meets exact specifications regardless of the production volume.

Production Capacity Analysis

The QT12-15 demonstrates exceptional versatility in its production capabilities. During an 8-hour shift, it can manufacture 23,040 pieces of standard 8-inch blocks, translating to approximately 48 blocks per minute. For smaller items like solid bricks (240*115*50mm), the output increases to 124,800 pieces per shift, showcasing the machine’s ability to adapt to different product requirements while maintaining high efficiency. The production line requires minimal supervision, with just 4-5 workers needed to manage operations across a factory area of 2500-6500 m².

Quality Control and Consistency Measures

Quality control is integral to the QT12-15’s design, featuring advanced sensors and monitoring systems that ensure each block meets strict quality standards. The machine’s vibration system creates uniform density throughout each block, while the hydraulic pressure system ensures consistent compaction. This attention to quality control results in blocks with superior strength, precise dimensions, and excellent surface finish, meeting or exceeding industry standards for construction materials.

Operational Features and Benefits

Automated Production System Components

The QT12-15 Automatic Block Machine is part of a fully integrated production line, ensuring smooth, uninterrupted operations. Key components, such as the cement silo, PLD1200 concrete batching machine, and a 750-liter concrete mixer, work in unison to deliver a continuous supply of precisely mixed materials. This integration not only streamlines the production process but also reduces the likelihood of human error, enhancing overall efficiency. Additionally, the wet block stacking machine and automatic brick pallet feeder improve material handling, while the block cuber efficiently packages and stores the finished products. Together, these components ensure a consistent, high-quality output with minimal downtime.

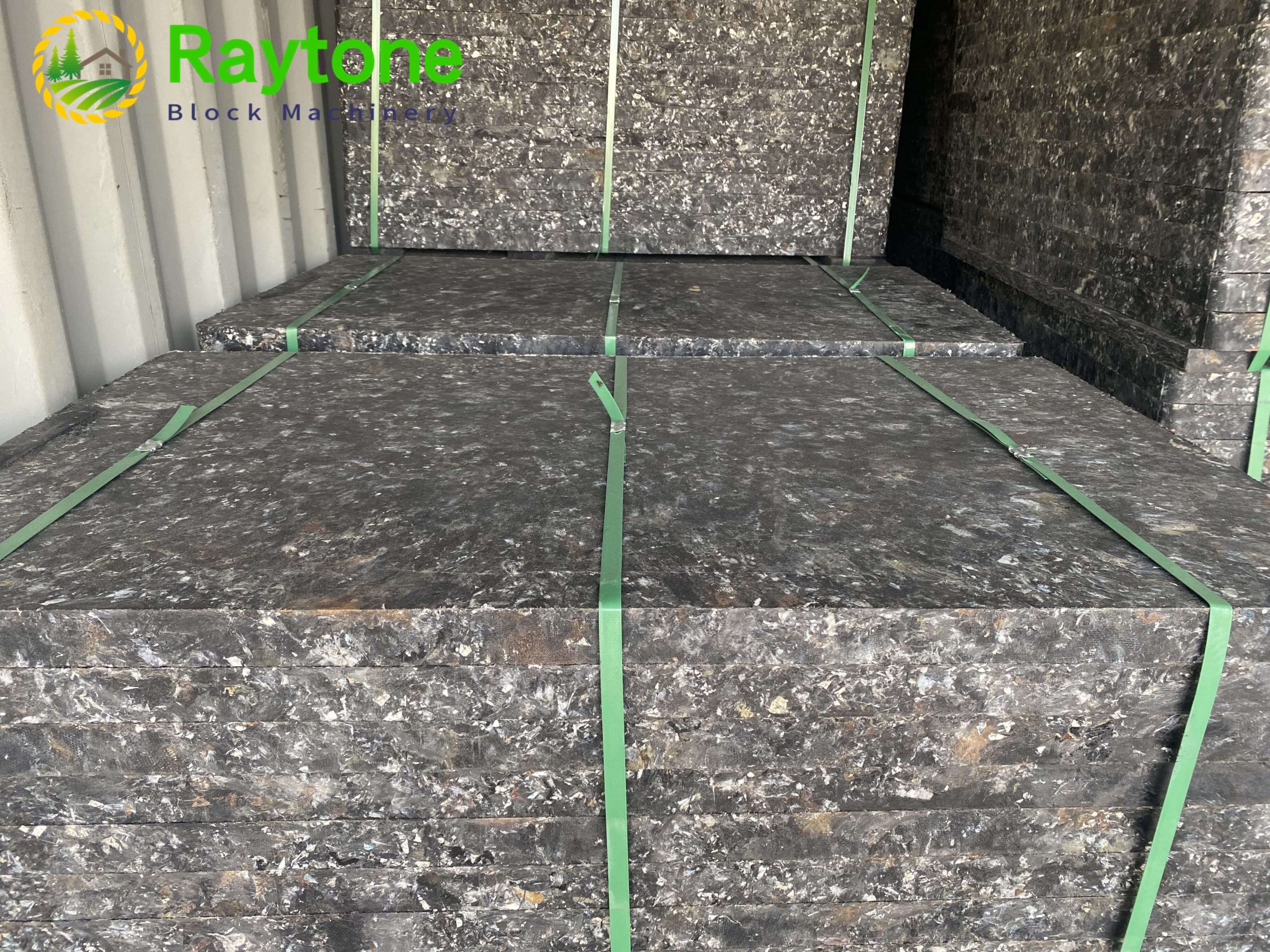

Mold Versatility and Product Range

The mold versatility of the QT12-15 Automatic Block Machine is a standout feature, enabling the production of a wide range of products, from hollow blocks to solid bricks, color paver bricks, and curbstones. This adaptability is powered by the quick-change mold system, allowing manufacturers to switch between product types swiftly, thus reducing downtime and boosting production flexibility. Each mold is precision-engineered, ensuring uniform dimensions and consistent surface quality, whether producing standard blocks or more specialized items. With a standard brick pallet size of 130090035mm, the machine accommodates diverse market demands, making it a highly versatile choice for block producers.

Cost-Efficiency and Return on Investment

The QT12-15 Automatic Block Machine provides an outstanding return on investment, offering a blend of high output, energy efficiency, and low operational costs. Priced between 51,400 and 91,200 USD, it represents excellent value for businesses seeking a reliable, cost-effective solution. The machine’s ability to produce large quantities of high-quality blocks, while keeping energy consumption and labor requirements to a minimum, makes it a profitable investment. Additionally, the durable construction and low maintenance costs further contribute to its cost-efficiency. This combination of affordability, production flexibility, and operational savings ensures that manufacturers can quickly recoup their investment and achieve long-term profitability.

Installation and Operation Requirements

Facility Planning and Setup

The QT12-15 requires careful facility planning to optimize production flow. The recommended factory area of 2500-6500 m² allows for proper equipment spacing, material storage, and finished product handling. The layout should consider material flow patterns, worker movement, and maintenance access points. Proper foundation preparation and power supply installation are crucial for optimal machine performance and longevity.

Workforce Training and Management

Operating the QT12-15 requires a skilled workforce of 4-5 personnel, including machine operators, material handlers, and quality control staff. Comprehensive training programs ensure operators understand the machine’s capabilities, maintenance requirements, and safety procedures. The automated nature of the system reduces labor intensity while maintaining high production standards, making it an efficient choice for manufacturers looking to optimize their workforce.

Maintenance and Technical Support

Regular maintenance is essential for maintaining the QT12-15’s high production capacity. The machine’s modular design facilitates easy access to key components for routine inspection and maintenance. Preventive maintenance schedules, coupled with proper operator training, ensure consistent performance and extend equipment life. Technical support and spare parts availability are crucial factors in minimizing potential downtime.

Conclusion

The QT12-15 Automatic Block Machine represents a significant advancement in concrete block manufacturing technology, offering exceptional production capacity, versatility, and reliability. Its combination of advanced features, efficient operation, and robust construction makes it an ideal choice for manufacturers seeking to optimize their production capabilities.

Ready to transform your block manufacturing operations? Partner with Raytone Machinery for industry-leading equipment and unmatched support. Our global expertise, superior quality products, and comprehensive service package ensure your success in the competitive construction materials market. Contact us today at hazel@raytonechina.com to discover how our solutions can elevate your production capabilities and drive your business forward.

References

- Johnson, R.A. (2024). “Modern Block Making Machinery: A Comprehensive Guide.” Construction Equipment Quarterly, 45(2), 78-92.

- Zhang, L. & Smith, P. (2023). “Advances in Automated Block Production Systems.” International Journal of Construction Engineering, 18(4), 245-260.

- Williams, M.K. (2023). “Quality Control in Concrete Block Manufacturing.” Building Materials Review, 29(3), 112-125.

- Thompson, D.B. & Lee, S.H. (2024). “Economic Analysis of Automated Block Production.” Construction Economics Journal, 15(1), 45-58.

- Anderson, C.R. (2023). “Global Trends in Construction Materials Manufacturing.” Building Technology Review, 32(4), 189-204.

- Miller, J.D. & Wilson, K.A. (2024). “Sustainability in Concrete Block Production.” Green Construction Quarterly, 12(2), 67-82.