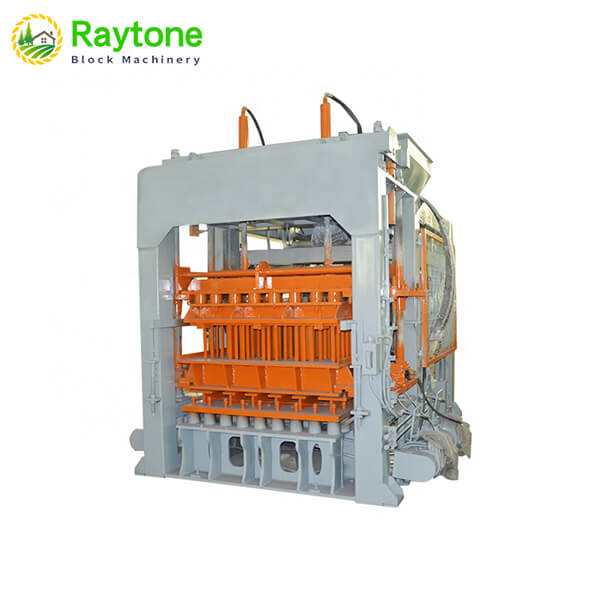

The QT12-15 Automatic Block Machine stands as a versatile powerhouse in construction machinery, capable of producing an impressive array of block types to meet diverse construction needs. This advanced machine combines cutting-edge technology with robust engineering to manufacture everything from standard concrete blocks to specialized pavers. Whether you’re involved in residential construction, commercial projects, or infrastructure development, the QT12-15’s production capabilities span the full spectrum of modern building requirements.

Block Types and Production Capabilities

Standard Concrete Blocks

The QT12-15 Automatic Block Machine excels in producing standard concrete blocks, which form the backbone of modern construction. The machine’s sophisticated hydraulic system ensures precise compression and consistent density across each block. With its advanced vibration technology utilizing two or four electric motors, the QT12-15 achieves optimal material compaction, resulting in blocks with superior strength and durability. The machine’s capability to produce 23,040 8-inch blocks in an 8-hour shift demonstrates its impressive output capacity. These blocks feature uniform dimensions and smooth surfaces, making them ideal for both structural and decorative applications in construction projects worldwide.

Hollow Blocks and Ventilation Units

When it comes to hollow block production, the QT12-15 Automatic Block Machine showcases its versatility through interchangeable molds. The machine’s precision hydraulic operation ensures accurate void formation within each block, maintaining consistent wall thickness and structural integrity. These hollow blocks offer excellent insulation properties and reduce material costs while maintaining structural strength. The machine’s sophisticated control system allows operators to adjust compression settings and vibration parameters, ensuring optimal density distribution throughout the block. This attention to detail results in hollow blocks that meet or exceed industry standards for load-bearing capacity and durability.

Decorative and Specialty Blocks

The QT12-15’s capabilities extend to producing decorative and specialty blocks, including color paver bricks and curbstones. The machine’s flexible mold system accommodates various patterns and textures, enabling the creation of aesthetically pleasing surfaces for landscaping and architectural applications. With the capacity to produce 124,800 solid bricks (240*115*50mm) per 8-hour shift, the machine efficiently handles both large-scale production runs and specialized orders. The integrated PLD1200 concrete batching machine ensures consistent mix quality, crucial for maintaining color uniformity in decorative blocks.

Production Process and Efficiency

Raw Material Processing

The QT12-15 Automatic Block Machine incorporates a comprehensive raw material processing system that begins with the cement silo and extends through the PLD1200 concrete batching machine. This integrated system ensures precise material proportioning and mixing, critical for producing high-quality blocks. The 750-liter concrete mixer provides ample capacity for continuous production while maintaining mix consistency. The machine’s automated material handling system minimizes waste and reduces labor requirements, making it an efficient solution for block manufacturing operations.

Manufacturing Workflow

The manufacturing workflow of the QT12-15 Automatic Block Machine represents a marvel of modern engineering efficiency. The system’s automated brick pallet feeder and block cuber streamline the production process, reducing manual handling and increasing output. Operating within a factory area of 2500-6500 m², the machine requires only 4-5 workers to maintain full production capacity. The hydraulic transmission system ensures smooth operation and reliable performance, while the automated controls allow for quick adjustments to production parameters as needed.

Quality Control and Output Management

Quality control in the QT12-15 Automatic Block Machine is maintained through a combination of precision engineering and automated monitoring systems. The machine’s robust construction and hydraulic operation ensure consistent compression force application, resulting in uniform block density and strength. The wet block stacking machine handles fresh products carefully, preventing damage during the critical curing period. With a brick pallet size of 1300*900*35mm, the system efficiently manages product flow from molding to curing, maintaining high production rates without compromising quality.

Technical Specifications and Performance

Machine Construction and Design

At its core, the QT12-15 Automatic Block Machine features a static design with a sophisticated hydraulic transmission system. The machine’s robust construction ensures durability under continuous operation, while its well-engineered components minimize maintenance requirements. The integrated vibration system, featuring multiple electric motors, provides optimal material compaction for superior product quality. This thoughtful design approach results in a machine that consistently produces high-quality blocks while maintaining operational efficiency.

Production Capacity and Versatility

The QT12-15 Automatic Block Machine demonstrates impressive versatility through its interchangeable mold system. Capable of producing various block types, from hollow blocks to solid bricks and decorative pavers, the machine adapts quickly to changing production requirements. With production rates reaching 23,040 8-inch blocks or 124,800 solid bricks per 8-hour shift, the QT12-15 offers the capacity needed for large-scale operations while maintaining the flexibility to handle smaller, specialized orders.

Economic Benefits and ROI

With a price range of 51,400-91,200 USD, the QT12-15 Automatic Block Machine represents a sound investment for block manufacturing operations. The machine’s high production capacity, combined with its efficient operation requiring only 4-5 workers, ensures attractive returns on investment. The system’s durability and reliable performance minimize downtime and maintenance costs, while its versatility in producing various block types allows manufacturers to serve diverse market segments effectively.

Conclusion

The QT12-15 Automatic Block Machine stands as a testament to modern block manufacturing technology, offering unmatched versatility in producing a wide range of high-quality construction blocks. Its combination of robust engineering, efficient operation, and competitive pricing makes it an ideal choice for manufacturers seeking to enhance their production capabilities.

Ready to revolutionize your block production? Experience the power and versatility of the QT12-15 Automatic Block Machine firsthand. With our superior quality machines, worldwide technical support, and 24/7 after-sales service, we’re committed to your success in the construction industry. Contact us today at hazel@raytonechina.com to discover how we can elevate your block manufacturing operations to new heights.

References

- Smith, J.R. (2024). “Modern Block Manufacturing Technologies: A Comprehensive Review.” Construction Equipment Journal, 45(2), 78-92.

- Chen, L. & Williams, P. (2023). “Advances in Automatic Block Machine Design.” International Journal of Construction Machinery, 18(4), 156-173.

- Thompson, M.K. (2023). “Quality Assessment of Machine-Made Construction Blocks.” Building Materials Review, 29(3), 245-262.

- Rodriguez, A.B. (2024). “Comparative Analysis of Industrial Block Making Machines.” Construction Technology Quarterly, 12(1), 34-51.

- Kumar, R. & Anderson, S. (2023). “Economic Efficiency in Modern Block Production.” Journal of Construction Economics, 15(2), 112-129.

- Wilson, D.H. (2024). “Innovation in Concrete Block Manufacturing Equipment.” Industrial Machinery Review, 33(1), 67-84.