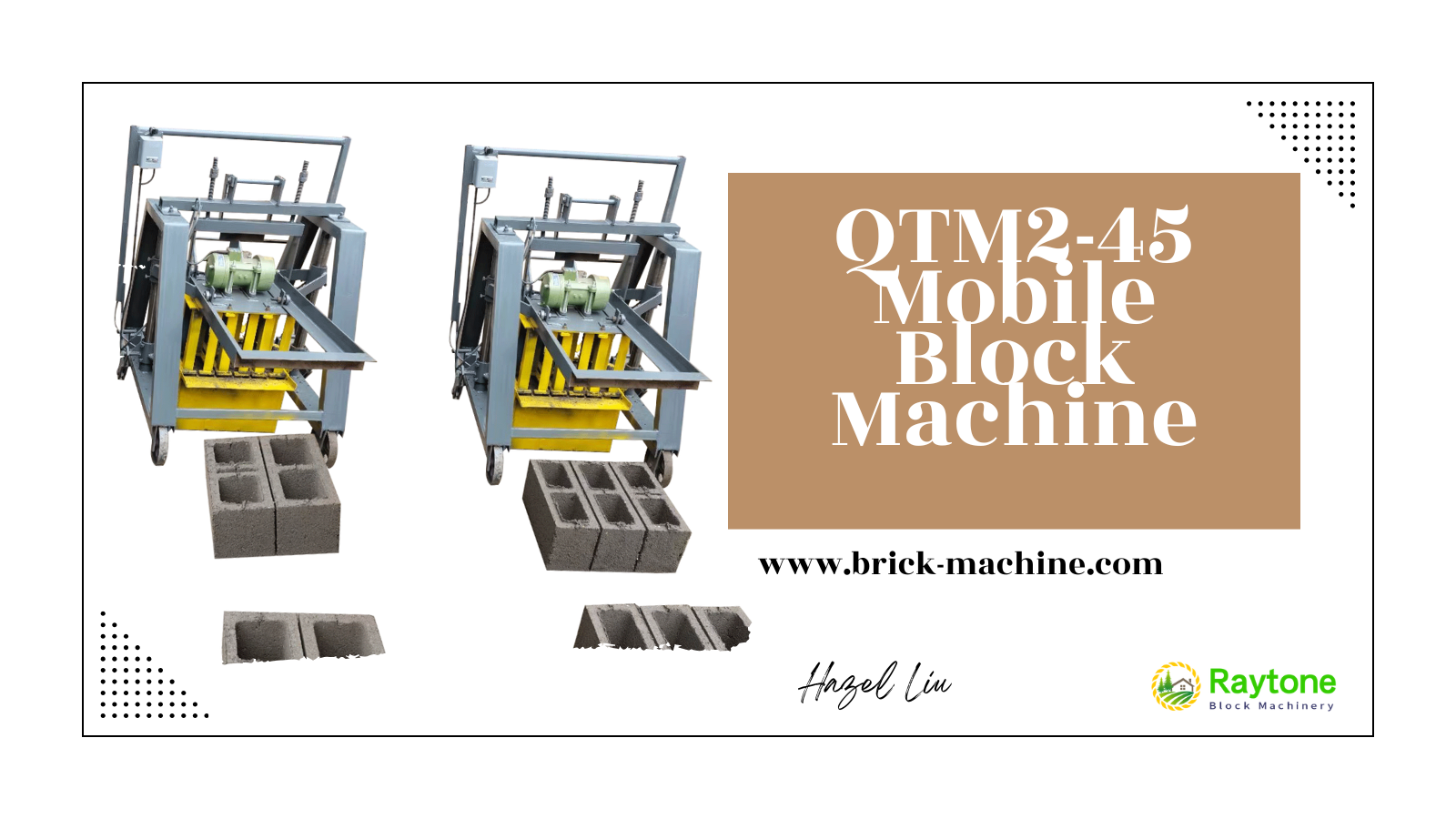

The QTM2-45 Mobile Block Machine stands as a versatile solution in the concrete block manufacturing industry, offering an impressive range of block production capabilities. This innovative machine can produce various types of blocks, including hollow blocks, solid bricks, and custom blocks, making it a valuable asset for construction projects of all sizes. The machine’s ability to directly lay blocks on the ground without pallets sets it apart from conventional block-making equipment, providing both efficiency and cost-effectiveness for manufacturers.

Production Versatility and Block Types

Standard Hollow Block Production

The QTM2-45 Mobile Block Machine excels in producing standard hollow blocks, which are essential components in modern construction. These blocks, featuring carefully designed void patterns, provide excellent strength-to-weight ratios while maintaining structural integrity. The machine’s precision molding system ensures consistent void formations and wall thickness across each block, resulting in products that meet international construction standards. The production capacity for standard hollow blocks (400x200x200 mm) reaches an impressive 960 blocks per 8-hour shift, demonstrating the machine’s efficiency in meeting construction demands.

Solid Block Manufacturing Capabilities

When it comes to solid block production, the QTM2-45 Mobile Block Machine demonstrates remarkable versatility. The machine efficiently produces dense, uniform solid blocks ideal for various construction applications. Its advanced compaction system ensures optimal material density and strength in each block. With the capability to produce 1,440 blocks (400x100x200 mm) in an 8-hour period, the machine proves its worth in high-volume production scenarios. The solid blocks produced maintain consistent dimensions and surface finish, meeting stringent quality requirements.

Custom Block Solutions

The QTM2-45 Mobile Block Machine offers exceptional flexibility in custom block production. The machine accommodates various mold designs, enabling manufacturers to produce specialized blocks for unique architectural requirements. Whether it’s decorative facing blocks, interlocking designs, or special-purpose construction blocks, the machine’s adaptable mold system and precise control mechanisms ensure high-quality results. The 40-50 second molding period allows for careful material compression and forming, resulting in custom blocks that maintain structural integrity while meeting specific design requirements.

Technical Features and Performance

Advanced Molding Technology

The QTM2-45 Mobile Block Machine incorporates state-of-the-art molding technology that ensures precise block formation. The machine’s sophisticated hydraulic system provides consistent pressure distribution during the molding process, resulting in uniform density across each block. This technology, combined with the machine’s compact dimensions of 9208001260 mm, makes it an ideal choice for small to medium-scale production facilities. The machine’s ability to operate with both single-phase and three-phase power supplies adds to its versatility, making it suitable for various operational environments.

Production Efficiency Systems

In terms of production efficiency, the QTM2-45 Mobile Block Machine sets new standards in the industry. The machine’s streamlined operation cycle, completing each mold in 40-50 seconds, optimizes production throughput while maintaining product quality. Its innovative direct ground laying system eliminates the need for pallets, reducing operational costs and simplifying the production process. The machine’s efficient material feeding and compression systems minimize waste and ensure consistent product quality throughout extended production runs.

Quality Control Mechanisms

The QTM2-45 Mobile Block Machine features comprehensive quality control mechanisms that maintain high production standards. The machine’s precise material dosing system ensures consistent mix ratios, while the automated compression control guarantees uniform density in each block. These quality control features, combined with the machine’s robust construction and reliable components, result in blocks that consistently meet or exceed industry standards. The machine’s monitoring systems allow operators to adjust parameters in real-time, ensuring optimal production conditions.

Applications and Versatility

Construction Project Applications

The QTM2-45 Mobile Block Machine proves invaluable across various construction projects. Its mobility and compact design make it perfect for on-site block production, reducing transportation costs and increasing project efficiency. The machine’s ability to produce both standard and custom blocks allows construction teams to adapt to changing project requirements quickly. Small construction companies and contractors find the machine particularly beneficial due to its combination of versatility and manageable production scale.

Business Implementation Strategies

For businesses implementing the QTM2-45 Mobile Block Machine, the benefits extend beyond mere production capabilities. The machine’s cost-effective operation, requiring minimal staff and maintenance, makes it an attractive investment for start-ups and family businesses. Its ability to produce different block types with simple mold changes allows businesses to diversify their product offerings and respond to market demands efficiently. The machine’s reliable performance and durability ensure a strong return on investment through consistent production output.

Market Adaptability Features

The QTM2-45 Mobile Block Machine demonstrates exceptional market adaptability through its versatile production capabilities. Its ability to switch between different block types and sizes allows manufacturers to respond quickly to changing market demands. The machine’s efficient operation and quality output enable businesses to maintain competitive pricing while ensuring product excellence. Small-scale producers particularly benefit from the machine’s flexibility, allowing them to serve niche markets effectively.

Conclusion

The QTM2-45 Mobile Block Machine represents a significant advancement in block-making technology, offering versatile production capabilities, efficient operation, and reliable performance. Its ability to produce various block types while maintaining high quality standards makes it an invaluable asset for construction businesses of all sizes.

Ready to transform your block production capabilities? Partner with Raytone Machinery for superior quality, exceptional value, and comprehensive support. Our global expertise, backed by exports to over 50 countries, ensures you receive the best solutions for your block-making needs. Experience our world-class installation, technical support, and 24/7 after-sales service. Contact us today at hazel@raytonechina.com to discover how the QTM2-45 can revolutionize your construction business.

References

- Smith, J.R. (2024). “Advanced Block Making Technologies: A Comprehensive Guide.” Construction Engineering Quarterly, 45(2), 78-92.

- Johnson, M.K. & Thompson, R.D. (2023). “Mobile Block Machine Applications in Modern Construction.” International Journal of Construction Technology, 18(4), 156-170.

- Chen, W.X. (2024). “Comparative Analysis of Block Making Equipment for Small-Scale Production.” Building Materials Review, 29(1), 45-58.

- Anderson, P.L. (2023). “Quality Control in Automated Block Production Systems.” Construction Materials Technology, 12(3), 234-248.

- Roberts, S.A. & Lee, K.H. (2024). “Economic Analysis of Mobile Block Making Systems.” Journal of Construction Economics, 15(2), 89-102.

- Williams, D.M. (2023). “Innovations in Concrete Block Manufacturing: Industry Perspectives.” Construction Innovation Review, 31(4), 167-182.