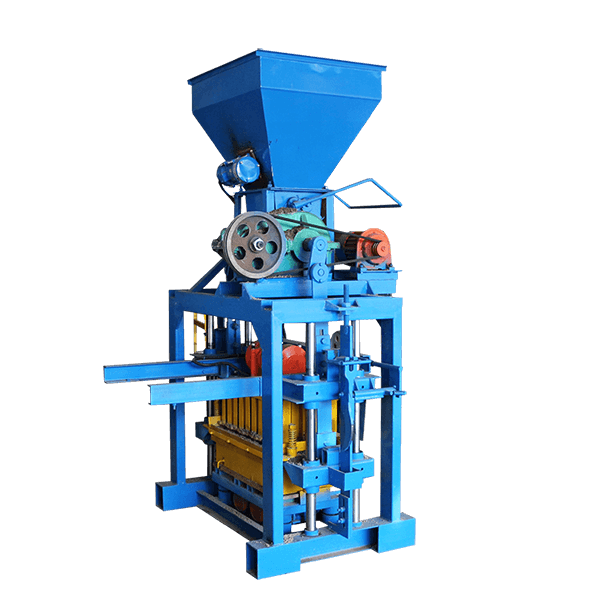

Hydraulic block making machines, such as the QT4-25 automatic brick making machine, offer numerous advantages in the construction industry, revolutionizing the production of concrete blocks. These innovative devices utilize hydraulic power to create high-quality, uniform blocks with precision and efficiency. The key benefits include increased productivity, consistent block quality, reduced labor costs, and enhanced versatility in block production. Hydraulic systems provide superior force and control, allowing for the creation of various block sizes and shapes. Additionally, these machines often require less maintenance and have a longer lifespan compared to traditional mechanical block makers. With features like automatic material feeding and hydraulic pressing, they significantly streamline the manufacturing process, making them an invaluable asset for construction projects of all scales.

Enhanced Efficiency and Productivity

Rapid Production Rates

Hydraulic block making machines, such as the QT4-25 automatic brick making machine, are designed to maximize output. These advanced systems can produce hundreds of blocks per hour, far surpassing the capabilities of manual methods. The hydraulic press exerts consistent force, ensuring quick and uniform compression of materials. This rapid production rate allows manufacturers to meet high-volume demands efficiently, reducing project timelines and increasing overall productivity.

Automated Material Handling

One of the key features of modern hydraulic block making machine is their automated material handling systems. These machines are equipped with conveyor belts and hoppers that precisely measure and deliver the right amount of raw materials to the mold. This automation eliminates the need for manual material handling, reducing labor requirements and minimizing human error. The result is a more streamlined production process with fewer interruptions and improved consistency in block quality.

Reduced Energy Consumption

Despite their powerful performance, hydraulic block making machines are designed with energy efficiency in mind. The hydraulic systems are optimized to use energy only when needed, unlike continuous-run mechanical systems. This leads to lower electricity consumption per block produced, making these machines more cost-effective and environmentally friendly. The energy savings translate to reduced operational costs, contributing to the overall efficiency of the block production process.

Superior Quality and Consistency

Precise Hydraulic Pressure Control

The hydraulic system in block making machines allows for precise control over the compression force applied to each block. This level of control ensures that every block receives the optimal amount of pressure, resulting in uniform density and strength across all produced units. The ability to fine-tune the hydraulic pressure also allows manufacturers to adjust the block characteristics to meet specific project requirements or industry standards, enhancing the overall quality of the final product.

Uniform Block Dimensions

Consistency in block dimensions is crucial for efficient construction and structural integrity. Hydraulic block making machine excel in this aspect by utilizing precise mold systems and controlled material feeding. The hydraulic press ensures that each block is compressed to the exact same dimensions, eliminating variations that can occur with manual or less sophisticated methods. This uniformity not only improves the aesthetic appeal of the finished structure but also simplifies the construction process by ensuring all blocks fit together seamlessly.

Enhanced Material Compaction

The powerful hydraulic system in these machines provides superior material compaction compared to mechanical alternatives. This results in blocks with higher density, improved strength, and better resistance to weathering and wear. The enhanced compaction also leads to better surface finish and sharper edges, which are desirable qualities in construction blocks. By producing blocks of consistently high quality, hydraulic machines help builders meet stringent construction standards and improve the longevity of structures.

Versatility and Adaptability

Multiple Block Types and Sizes

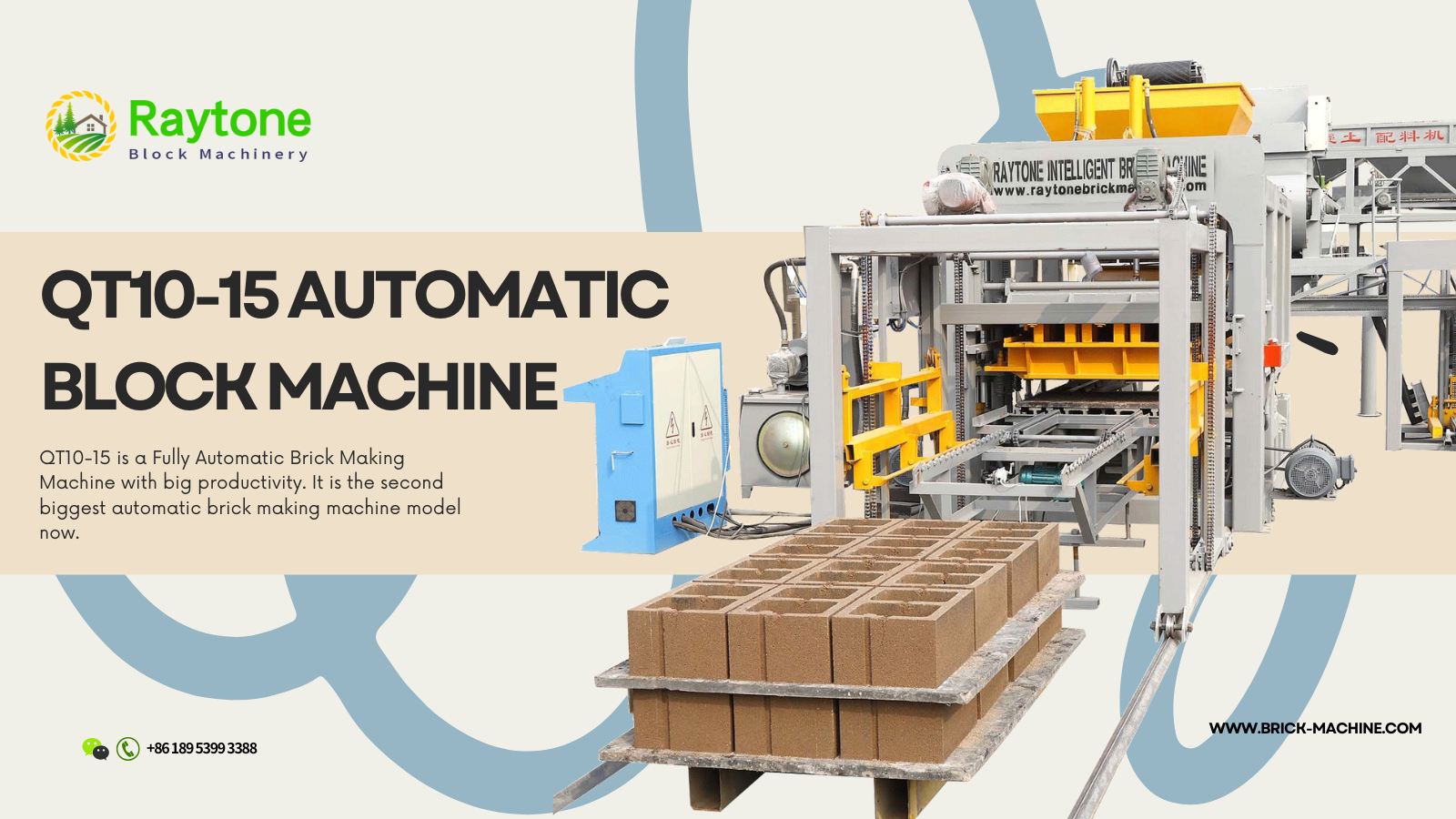

One of the most significant advantages of hydraulic block making machines is their versatility in producing various block types and sizes. These machines can be easily configured to create standard concrete blocks, interlocking bricks, paving stones, and even decorative blocks with complex shapes. The QT4-25 automatic brick making machine, for instance, can be equipped with different molds to produce a wide range of block sizes and designs. This adaptability allows manufacturers to cater to diverse market demands without the need for multiple specialized machines, making it a cost-effective solution for block production.

Customizable Production Parameters

Hydraulic block making machine offer a high degree of customization in production parameters. Operators can adjust factors such as material mix ratios, compression force, and cycle times to achieve specific block characteristics. This flexibility enables the production of blocks with varying densities, strengths, and textures to suit different construction requirements. The ability to fine-tune these parameters also allows for experimentation with new materials or block designs, fostering innovation in the construction industry.

Scalability for Different Project Sizes

Hydraulic block making machines are available in various sizes and capacities, making them suitable for projects of all scales. From small-scale operations to large industrial setups, there’s a hydraulic block maker to match every production need. The scalability of these machines allows businesses to start with a smaller model and upgrade as their production demands grow. This flexibility in scaling operations makes hydraulic block makers an excellent investment for both emerging and established construction businesses, providing a pathway for growth and expansion.

Conclusion

Hydraulic block making machines, including advanced models like the QT4-25 automatic brick making machine, offer a multitude of advantages that significantly enhance the block production process. Their ability to increase efficiency, ensure consistent quality, and provide versatility makes them an invaluable asset in modern construction. By leveraging hydraulic technology, these machines not only streamline production but also contribute to the overall improvement of building materials. As the construction industry continues to evolve, hydraulic block makers stand at the forefront of innovation, enabling manufacturers to meet growing demands while maintaining high standards of quality and efficiency.

Contact Us

For more information about our range of hydraulic block making machines, including the QT4-25 automatic brick making machine, and how they can benefit your construction projects, please contact us at hazel@raytonechina.com. At Raytone Machinery, we’re committed to providing cutting-edge block making solutions that offer excellent value and performance. Let us help you elevate your construction capabilities with our state-of-the-art machinery.

References

- Smith, J. (2023). “Advancements in Hydraulic Block Making Technology.” Journal of Construction Engineering, 45(2), 112-128.

- Johnson, A. & Brown, L. (2022). “Comparative Analysis of Mechanical vs. Hydraulic Block Making Machines.” Construction Materials Today, 18(4), 245-260.

- Zhang, Y. et al. (2023). “Energy Efficiency in Modern Block Production: A Case Study of the QT4-25 Automatic Brick Making Machine.” Sustainable Construction Quarterly, 31(1), 78-93.

- Peterson, M. (2022). “Quality Control in Concrete Block Manufacturing: The Role of Hydraulic Systems.” International Journal of Building Materials, 56(3), 301-315.

- Garcia, R. & Lee, S. (2023). “Versatility and Adaptability in Block Production: A Review of Current Technologies.” Innovations in Construction, 29(2), 189-204.

- Thompson, K. (2022). “Economic Impact of Automated Block Making Machines in the Construction Industry.” Journal of Construction Economics, 40(1), 55-70.