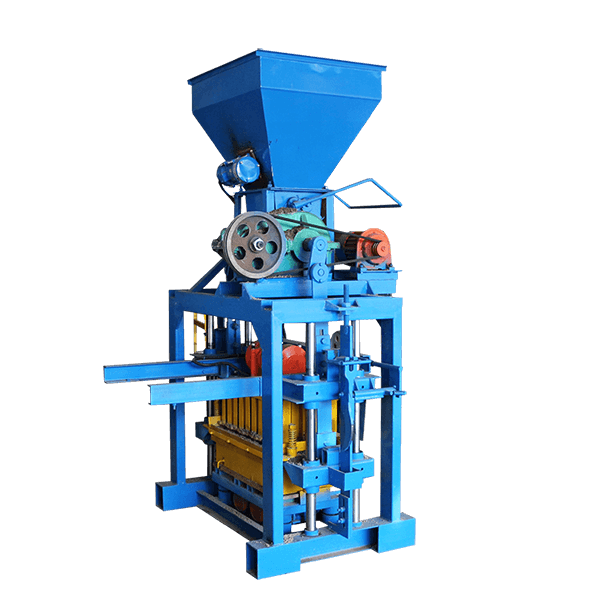

QT4-24 Semi Automatic Cement Block Machine

The QT4-24 Semi Automatic Cement Block Machine is a semi-automatic block making machine, capable of producing various blocks with a daily output of 4,428 pieces per 8 hours for 8-inch hollow blocks, priced between $6,000 and $12,000.

Introduction Of QT4-24 Semi Automatic Cement Block Machine

The QT4-24 Semi Automatic Cement Block Machine is a highly popular and versatile option for producing a wide range of concrete products, including hollow blocks, paver bricks, interlocking blocks, and curbstones, all with customizable brick molds.

The QT4-24 Semi Automatic Cement Block Machine line has a daily production capacity of 4,428 8-inch hollow blocks in 8 hours.

The price range for the QT4-24 Semi Automatic Cement Block Machine line is between $6,000 and $12,000, depending on the configuration.

Advantages of the QT4-24 Semi Automatic Cement Block Machine

1. Large-Diameter Mixer:

Equipped with a 1200mm diameter mixer, the mixer also features 10mm higher steel, preventing raw materials from spilling out during the mixing process and ensuring stable production.

2. High-Configuration Reducer and Chain Conveyor:

The QT4-24 Semi Automatic Cement Block Machine is equipped with a JZQ350 reducer and a link chain conveyor, providing more stability and durability compared to the commonly used JZQ250 reducer and V-belt conveyor, extending the machine’s lifespan.

3. Advanced Automated Control System:

The QT4-24 Semi Automatic Cement Block Machine features an automatic up-mould lifting system and an automatic vibration system under the bottom mould, improving production efficiency, reducing manual intervention, and delivering better vibration effects without damaging machine components.

Get Free Quote of QT4-24 Semi Automatic Cement Block Machine

QT4-24 Semi-Automatic Block Machine Overview

QT4-24 is a semi-automatic cement block machine that can produce various sizes of hollow blocks, paver bricks, interlocking blocks, and curbstones by changing molds. It is highly popular for its affordability and ease of operation.

- Production Capacity: 8-inch Hollow Blocks: Up to 4,428 pieces per 8-hour shift.

- Price Range: $6,000 to $12,000 USD, depending on the configuration.

1. Improved Durability and Strength:

The mixer provides greater durability, ensuring longer machine lifespan and more reliable performance.

2. Increased Production Efficiency:

The automatic control system and suspended vibration motors reduce the need for manual intervention, improving overall productivity and reducing operational errors.

3. Longer-Lasting Components:

The high-quality block trolley wheels last up to 2 years.This reduces the frequency of replacements and maintenance costs.

4. Cost-Effective with High Performance:

The high configuration offers superior performance, ensuring more efficient and consistent production. This higher investment leads to better value in the long term.

QT4-24 Semi Automatic Cement Block Machine Line Basic Requirements for Production Start

| Land area | 300 Square Meters | Water Consumption | 2.5 T/day |

| Workshop area | 50 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 6 workers | Power Consumption | 22.45KW*8 Hours=179.6 KWH; |

| Cement Consumption | 7.3Tons per day | Sand consumption | 29.2 tons per day |

| Crushed stones consumption | 36.5 tons per day |

Detailed Introduction of QT4-24 Semi Automatic Cement Block Machine Line

| Number | Item | Function |

| 1 | JQ350 Concrete mixer | Mix raw material including cement, sand, stone |

| 2 | 6M Belt Conveyor | Carry mixed material from mixer to Block machine |

| 3 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 4 | Manual Trolley | Transport the produced blocks to curing area |

Paraments Of QT4-24 Semi Automatic Cement Block Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area:60 square meters

Factory area:600 square meters Labor quantity:4 Machine power:13.25kw Vibration force:50kn Reducer model: JZQ250 Diesel Generator Capacity: 30KVA Machine size: 1800*1500*2520mm Machine weight: 1500kg |

QT4-24 Semi Automatic Cement Block Machine Daily Production Capacity

| Theoretical production capacity for QT4-24 Semi Automatic Cement Block Machine | ||||||

| Size(LxWxH) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |  |

24 | 3 | 415 | 3321 |

| (2) | hollow block 400*200*200 |  |

24 | 4 | 554 | 4428 |

| (3) | hollow block 400*150*200 |  |

24 | 5 | 692 | 5535 |

| (4) | hollow block 400*100*200 |  |

24 | 7 | 969 | 7749 |

| (5) | Solid Brick 240*50*115 |  |

24 | 26 | 3598 | 28782 |

| (6) | Porous Brick 240*115*90 |  |

24 | 12 | 1661 | 13284 |

| (7) | Curbstone 500*200*300 |  |

24 | 2 | 277 | 2214 |

| (8) | “I” shape paver brick without color 200*163*60 |  |

24 | 8 | 1107 | 8856 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |  |

24 | 12 | 1661 | 13284 |

| (10) | Holland Brick without color 200*100*60 |  |

24 | 14 | 1938 | 15498 |

| (11) | Square Paver wihtout color 250*250*60 |  |

24 | 3 | 415 | 3321 |

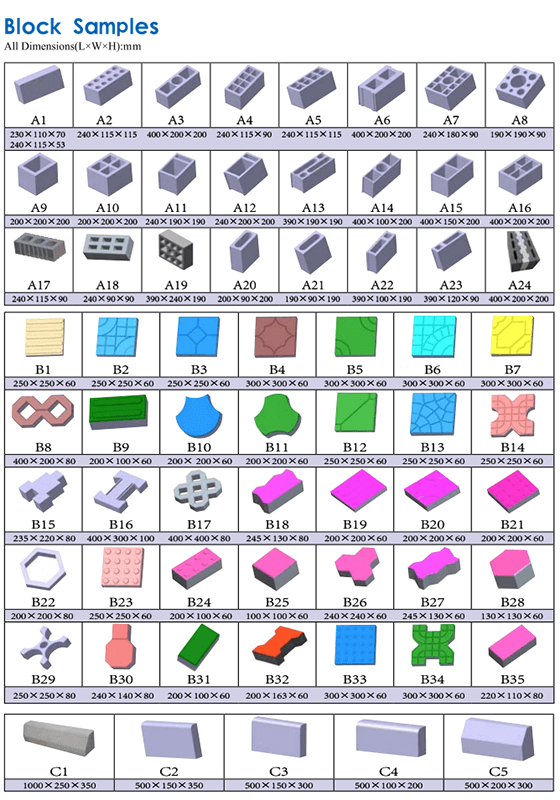

QT4-24 Semi Automatic Cement Block Machine - Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT4-24 Semi Automatic Cement Block Machine Full Production Line

1. How many workers are needed for the QT4-24 Semi Automatic Cement Block Machine line?

Simple QT4-24 Semi Automatic Cement Block Machin Line:

For a basic semi-automatic brick making line, 2 workers are needed to manually feed raw materials into the pan mixer and control the mixing process. 1 worker operates the main QT4-24 block machine, while 2 workers transport the produced blocks to the curing area. Additionally, 1 worker waters the blocks for curing, totaling 6 workers required.

QT4-24 Semi Automatic Cement Block Machine with Stacking Machine:

With the addition of a stacking machine, the process becomes more automated. 1 worker operates a small wheel loader to load raw materials into the pan mixer and controls the mixer. 1 worker operates the main brick machine, while 1 worker drives an electric forklift to transport the blocks to the curing area. 1 worker is responsible for curing the blocks by watering them. In total, only 4 workers are needed with the stacking machine in place.

2. What is the brick pallet size?

The size of the brick pallet depends on the machine configuration:

- With Stacking Machine: For a QT4-24 Semi Automatic Cement Block Machine Line with a stacking machine, the recommended brick pallet size is 880mm x 550mm x 22mm. This size ensures optimal performance with the stacking system for easy block handling and storage.

- Without Stacking Machine: If not using a stacking machine, the standard pallet size of 850mm x 550mm x 20mm is sufficient. This option also helps to reduce costs associated with pallets while still providing effective performance for semi-automatic brick production.

Working Videos

1. How many workers are needed for the QT4-24 Semi Automatic Cement Block Machine line?

Simple QT4-24 Semi Automatic Cement Block Machin Line:

For a basic semi-automatic brick making line, 2 workers are needed to manually feed raw materials into the pan mixer and control the mixing process. 1 worker operates the main QT4-24 block machine, while 2 workers transport the produced blocks to the curing area. Additionally, 1 worker waters the blocks for curing, totaling 6 workers required.

QT4-24 Semi Automatic Cement Block Machine with Stacking Machine:

With the addition of a stacking machine, the process becomes more automated. 1 worker operates a small wheel loader to load raw materials into the pan mixer and controls the mixer. 1 worker operates the main brick machine, while 1 worker drives an electric forklift to transport the blocks to the curing area. 1 worker is responsible for curing the blocks by watering them. In total, only 4 workers are needed with the stacking machine in place.

2. What is the brick pallet size?

The size of the brick pallet depends on the machine configuration:

- With Stacking Machine: For a QT4-24 Semi Automatic Cement Block Machine Line with a stacking machine, the recommended brick pallet size is 880mm x 550mm x 22mm. This size ensures optimal performance with the stacking system for easy block handling and storage.

- Without Stacking Machine: If not using a stacking machine, the standard pallet size of 850mm x 550mm x 20mm is sufficient. This option also helps to reduce costs associated with pallets while still providing effective performance for semi-automatic brick production.

Related Products

Related News

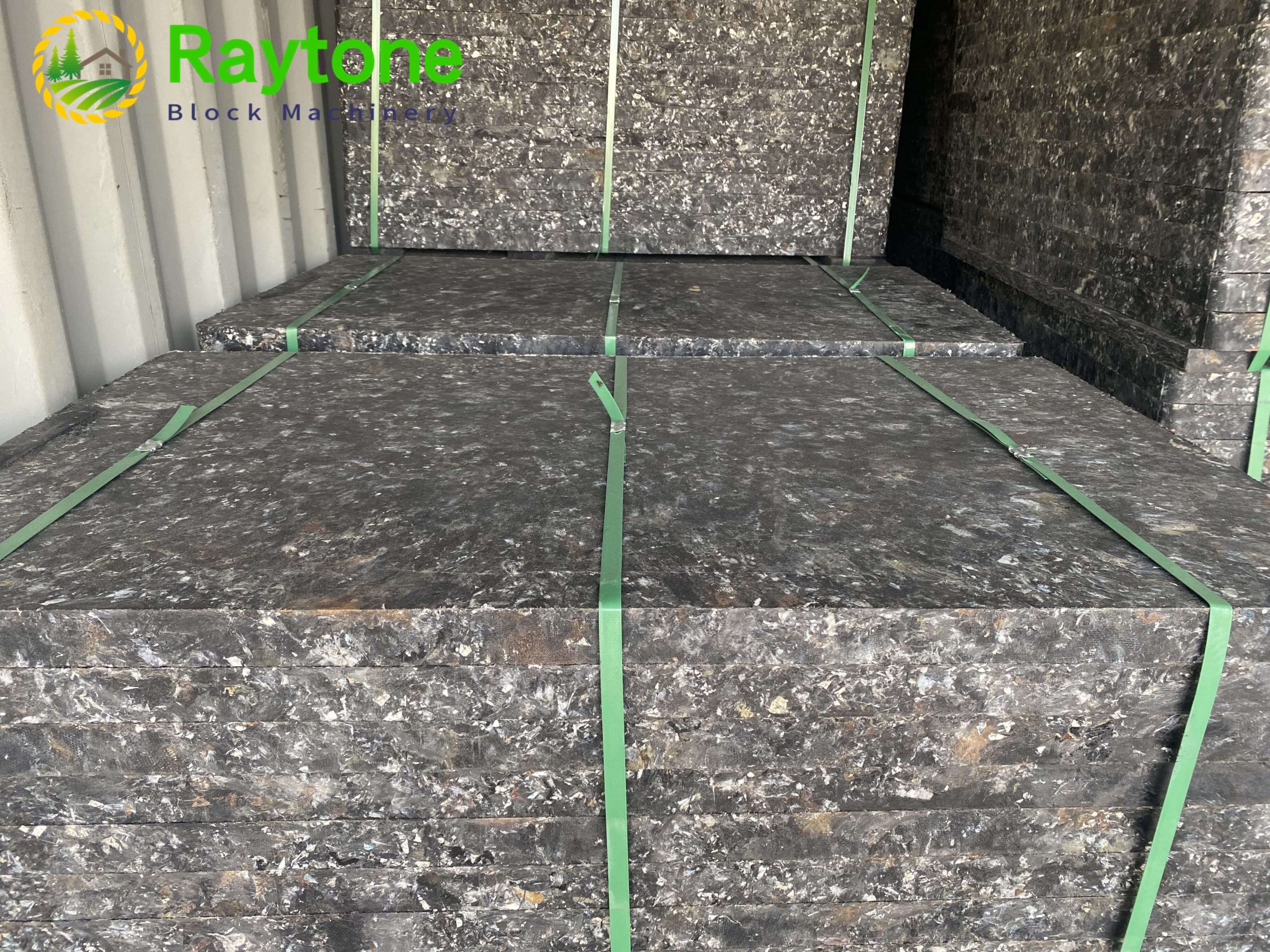

When it comes to choosing the right pallet for block-making operations, the options often boil down to traditional materials like […]

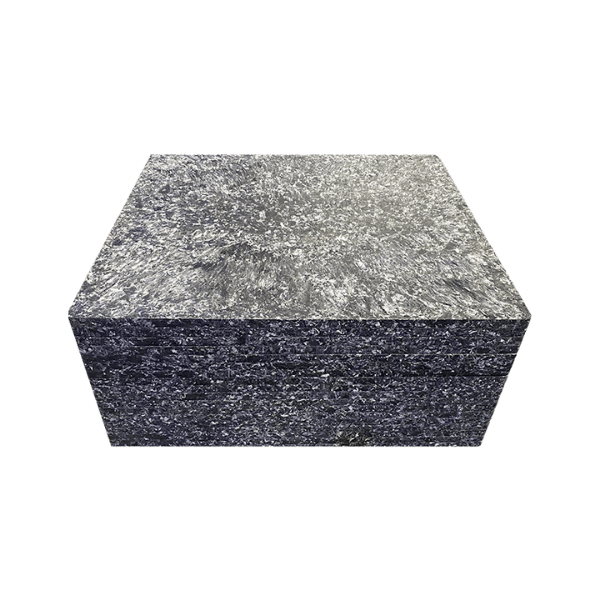

Yes, GMT brick pallets are highly resistant to both moisture and mold, making them an excellent choice for block machine operations. […]

Yes, GMT brick pallets are indeed eco-friendly. Made from glass fiber mat reinforced thermoplastic composite material, these pallets utilize leftover materials, […]

Setting up a manual block machine like the QT4-35 requires careful planning and consideration of several key elements. To successfully […]

Manual block machines, like the QT4-35 manual brick making machine, offer impressive productivity for small to medium-sized construction projects. These […]

The hollow block making machine production process is remarkably efficient due to its advanced automation, streamlined workflow, and precise control […]

The hollow block making machine production process is a fascinating journey that transforms raw materials into sturdy, versatile construction components. […]

Hollow block making machines are essential equipment in the construction industry, revolutionizing the production of concrete blocks. These versatile machines […]