QT4-25 Automatic Cement Block Machine

The QT4-25 automatic block machine is a mechanical concrete block maker that produces hollow blocks, interlocking bricks, and curbstones, with a daily output of up to 4608 pieces and using 880*550*22mm GMT pallets.

Introduction Of QT4-25 Automatic Cement Block Machine

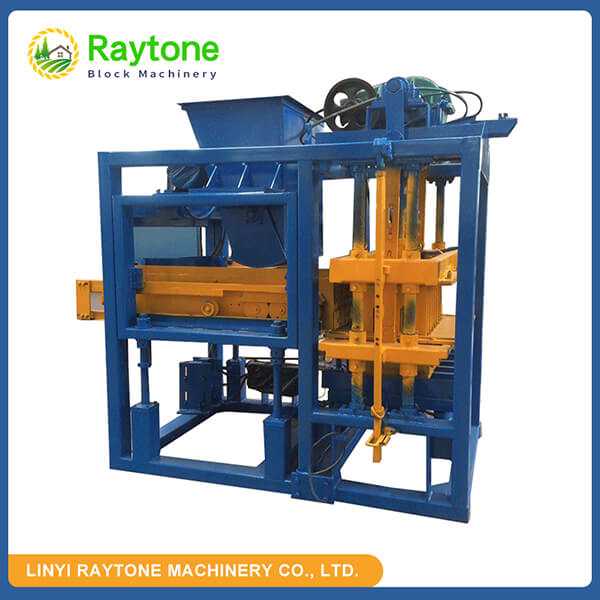

The QT4-25 Automatic Cement Block Machine is a mechanical-driven concrete block making machine ideal for producing various block types, including hollow blocks, interlocking bricks, paver blocks,and curbstones.

Engineered for high efficiency, it completes each mould cycle in 25 seconds, producing up to 4608 pieces of 8-inch hollow blocks per day. Designed for flexibility, the QT4-25 uses 880*550*22mm GMT pallets, providing strong support for uniform, high-density block production.

This QT4-25 Automatic Cement Block Machine is available in a price range of 9600 to 25000 USD, depending on configuration and the number of block moulds included, offering an accessible investment for expanding concrete block production capabilities.

Advantages of the QT4-25 Automatic Cement Block Machine

1. Reliable Brand Motors: The QT4-25 Automatic Cement Block Machine uses China’s famous COPPER brand motors, known for durability and reliability. These high-quality motors ensure stable operation and reduce long-term maintenance costs.

2. Advanced Welding Process: Raytone block machine manufacturer uses Carbon Dioxide Arc Welding, ensuring strong, stable welding points with a smooth surface finish.

3. Durable GMT Brick Pallets: The machine is compatible with 880*550*22mm GMT pallets, known for their durability and strength, providing a stable platform that supports consistent, high-quality block production.

4. Flexible and Cost-Effective Pricing Options: Priced between 9600 USD and 25000 USD based on configuration and number of block moulds, the QT4-25 Automatic Cement Block Machine offers cost-effective choices for various production needs, maximizing return on investment for brick and block manufacturing businesses.

Get Free Quote of QT4-25 Automatic Cement Block Machine

QT4-25 Automatic Cement Block Machine Overview

The QT4-25 automatic cement block machine is a mechanically driven concrete block machine capable of producing hollow blocks, interlocking blocks, curbstones, and plain pavers. However, it does not produce colored pavers due to the lack of a pigment feeding machine.

- Production Capacity: 8-inch hollow blocks: 4 pieces per mold at a cycle time of 25 seconds, or 4,608 pieces per day.

- Price Range: $9,600 to $25,000 USD, depending on number of molds and other configurations.

- Pallet Specifications: Uses 880×550×22mm GMT brick pallets.

1. Versatile Block Production: The QT4-25 Automatic Cement Block Machine is capable of producing various block types, including hollow blocks, interlocking blocks, paver bricks, and curbstones, making it an ideal solution for diverse brick and block manufacturing needs.

2. High-Frequency Vibration System: Equipped with a high-frequency vibration motor with large amplitude and strong excitation force, this QT4-25 Automatic Cement Block Machine delivers uniform compaction, enhancing the density and durability of finished blocks.

3. Efficient Production Cycle: With a 25-second mould cycle, QT4-25 Automatic Cement Block Machine achieves high efficiency, producing up to 4608 pieces of 8-inch hollow blocks per day,making it an optimal choice for high-volume output.

4. Precision Mould Manufacturing: The QT4-25 block moulds are produced through CNC linear cutting for high accuracy and treated with high-temperature heat for hardness and wear resistance, resulting in a significantly extended mould lifespan.

QT4-25 Automatic Cement Block Machine Basic Requirements for Production Start

| Land area | 1000 SQM | Water Consumption | 2.88 T/day |

| Workshop area | 60 SQM | Electricity Voltage &Frequency | 220V/380V/415V; 50HZ/60HZ |

| labors | 6 workers | Power Consumption | 34.8KW*8 Hours= 278.4KWH |

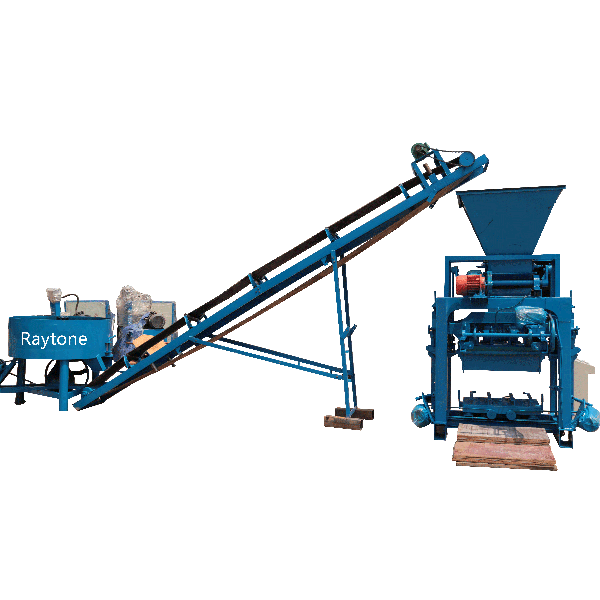

Detailed Introduction of QT4-25 Automatic Cement Block Machine Line

| Number | Item | Function |

| 1 | JQ500 Concrete mixer | Mix raw material including cement, sand, stone |

| 2 | 6M Belt Conveyor | Carry mixed material from mixer to Block machine |

| 3 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 4 | Single Row Block Stacker Machine | Stack the finished hollow blocks to several layers |

| 5 | Manual Trolley | Transport the produced blocks to curing area |

Paraments Of QT4-25 Automatic Cement Block Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area :100 square meters

Factory area:1200 square meters Labor quantity:4 Machine power:21.5kw Vibration force:50-65 KN Moulding Period:15-20 S Diesel Generator Capacity: 50KVA Machine size: 3600*1600*2400mm Machine weight: 4000kg |

QT4-25 Automatic Cement Block Machine Daily Production Capacity

| Theoretical production capacity for QT4-25 Semi Automatic Cement Block Machine | ||||||

| Size(LxWxH) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |  |

25 | 3 | 432 | 3456 |

| (2) | hollow block 400*200*200 |  |

25 | 4 | 576 | 4608 |

| (3) | hollow block 400*150*200 |  |

25 | 5 | 720 | 5760 |

| (4) | hollow block 400*100*200 |  |

25 | 7 | 1008 | 8064 |

| (5) | Solid Brick 240*53*115 |  |

25 | 26 | 3744 | 29952 |

| (6) | Porous Brick 240*115*90 |  |

25 | 12 | 1728 | 13824 |

| (7) | Curbstone 500*200*300 |  |

25 | 2 | 288 | 2304 |

| (8) | “I” shape paver brick without color 200*163*60 |  |

25 | 8 | 1152 | 9216 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |  |

25 | 12 | 1728 | 13824 |

| (10) | Holland Brick without color 200*100*60 |  |

25 | 14 | 2016 | 16128 |

| (11) | Square Paver without color 250*250*60 |  |

25 | 3 | 432 | 3456 |

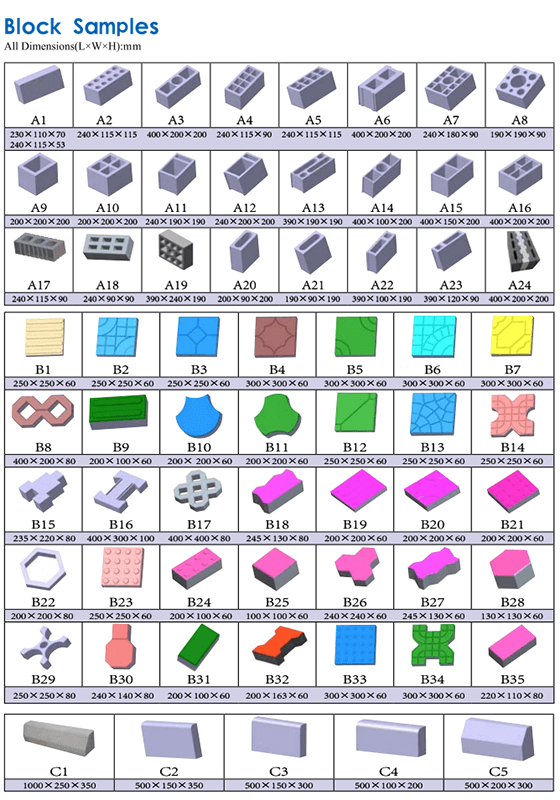

QT4-25 Automatic Cement Block Machine - Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT4-25 Automatic Cement Block Machine Full Production Line

1. What’s the capacity of diesel generator for this QT4-25 automatic cement block machine line?

It needs 50 KVA of a diesel generator.

2. How many labors are required for the QT4-25 Automatic Cement Block Machine Line?

Under normal conditions, it takes 6 workers: 1 worker feeds raw materials into the concrete mixer. 1 worker feeds brick pallets and operates the host brick machine; 2 workers carry the finished blocks to the curing area; 2 workers water the blocks and stack after drying.

3. What is the size of the main electric cable from the electricity transformer?

Copper 3*25+1*16mm electric cable shall be adopted to 380V 3-phase system, or 3*35+1*16mm electrical copper cable for 220V 3-phase.

4. What is the general proportion of concrete block basic raw materials?

Proportion of raw materials for your reference:

- Concrete: 10% of cement, 30% of sand, 60% of small stones

- 10% cement, 90% stone powder

- 10% cement, 30% fly ash, 60% stone powder

Working Videos

1. What’s the capacity of diesel generator for this QT4-25 automatic cement block machine line?

It needs 50 KVA of a diesel generator.

2. How many labors are required for the QT4-25 Automatic Cement Block Machine Line?

Under normal conditions, it takes 6 workers: 1 worker feeds raw materials into the concrete mixer. 1 worker feeds brick pallets and operates the host brick machine; 2 workers carry the finished blocks to the curing area; 2 workers water the blocks and stack after drying.

3. What is the size of the main electric cable from the electricity transformer?

Copper 3*25+1*16mm electric cable shall be adopted to 380V 3-phase system, or 3*35+1*16mm electrical copper cable for 220V 3-phase.

4. What is the general proportion of concrete block basic raw materials?

Proportion of raw materials for your reference:

- Concrete: 10% of cement, 30% of sand, 60% of small stones

- 10% cement, 90% stone powder

- 10% cement, 30% fly ash, 60% stone powder

Related Products

Related News

Yes, GMT brick pallets are highly resistant to both moisture and mold, making them an excellent choice for block machine operations. […]

Manual block machines are essential tools in the construction industry, offering a cost-effective solution for producing various types of concrete […]

The hollow block making machine production process is remarkably efficient due to its advanced automation, streamlined workflow, and precise control […]

The hollow block making machine production process is a fascinating journey that transforms raw materials into sturdy, versatile construction components. […]

Hollow block making machines are essential equipment in the construction industry, revolutionizing the production of concrete blocks. These versatile machines […]

Improving efficiency with a hollow block making machine involves optimizing various aspects of the production process. Key strategies include proper […]

Maintaining your automatic hydraulic concrete block machine is crucial for ensuring its longevity, efficiency, and consistent production of high-quality blocks. […]

If you’re in the market for an automatic hydraulic concrete block machine, you’re in luck. The internet has made it […]