Cement brick making machines have revolutionized the construction industry, offering a reliable, fast, and efficient solution for producing high-quality building materials. These innovative machines combine cutting-edge technology with robust design to streamline the brick production process, resulting in consistent output and reduced labor costs. Whether you’re a small-scale contractor or a large construction firm, investing in a cement brick making machine can significantly boost your productivity and help you meet the growing demand for sustainable building materials.

The Evolution of Cement Brick Making Technology

From Manual to Automated: A Brief History

The journey of cement brick production has come a long way from its humble beginnings. In the early days, bricks were laboriously crafted by hand, a time-consuming process that limited production capacity. As the demand for construction materials grew, innovators sought ways to mechanize the process. The first rudimentary brick-making machines emerged in the 19th century, laying the groundwork for the sophisticated equipment we see today.

Technological Advancements in Modern Machines

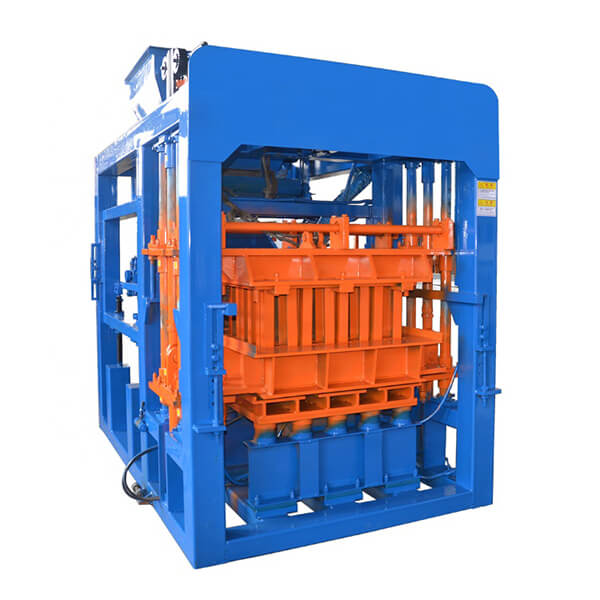

Modern cement brick making machines incorporate a host of technological advancements that enhance their performance and reliability. Computer-controlled systems ensure precise material mixing and molding, while advanced hydraulics provide the necessary pressure for compaction. These machines also feature improved energy efficiency, reducing operational costs and environmental impact. Sensors and diagnostic tools allow for real-time monitoring and quick troubleshooting, minimizing downtime and maximizing productivity.

The Impact on Construction Efficiency

The introduction of automated cement brick making machines has had a profound impact on construction efficiency. These machines can produce thousands of bricks per day, far surpassing manual production rates. This increased output has enabled construction projects to progress more rapidly, meeting tight deadlines and reducing overall project costs. Moreover, the consistency in brick quality has improved building standards and durability, contributing to safer and more sustainable structures.

Key Features of High-Performance Cement Brick Machines

Versatility in Brick Types and Sizes

One of the standout features of modern cement brick making machines is their versatility. These machines can produce a wide array of brick types, including solid bricks, hollow blocks, and interlocking pavers. The ability to adjust mold sizes allows manufacturers to create bricks of various dimensions, catering to different architectural requirements and regional preferences. This flexibility ensures that a single machine can meet diverse market demands, making it a valuable asset for any construction material supplier.

Precision Control Systems

High-performance cement brick machines are equipped with sophisticated control systems that ensure precision in every aspect of the production process. PLC (Programmable Logic Controller) systems allow operators to fine-tune parameters such as mixing ratios, compaction pressure, and curing times. This level of control results in bricks with consistent density, strength, and appearance. Advanced machines also offer touch-screen interfaces for easy operation and real-time production data monitoring, enabling manufacturers to maintain high quality standards and optimize their processes continuously.

Durability and Low Maintenance Design

Reliability is crucial in brick production, and top-tier cement brick making machines are built to withstand the rigors of continuous operation. Manufacturers use high-grade materials and robust construction techniques to ensure longevity and minimize wear and tear. Components such as molds, vibrators, and hydraulic systems are designed for easy maintenance and replacement, reducing downtime and maintenance costs. Many machines also feature self-lubricating systems and dust-proof enclosures, further enhancing their durability and reducing the need for frequent servicing.

Maximizing Efficiency in Cement Brick Production

Optimizing Raw Material Selection and Mixing

The quality of cement bricks begins with the selection and mixing of raw materials. High-efficiency cement brick making machines often include integrated mixing systems that ensure the perfect blend of cement, aggregates, and additives. Proper material selection and precise mixing ratios are crucial for producing bricks with optimal strength and durability. Advanced cement brick making machines may feature automated material feeding systems and moisture sensors to maintain consistent mix quality, even when dealing with variations in raw material properties.

Streamlining the Production Workflow

Efficient cement brick production relies on a well-organized workflow. Modern brick making machines are designed to integrate seamlessly with other equipment such as conveyors, stackers, and curing systems. This integration creates a smooth production line that minimizes material handling and reduces labor requirements. Automated pallet handling systems and robotic arms for brick stacking further enhance efficiency, allowing for continuous operation with minimal human intervention. By optimizing the entire production process, manufacturers can achieve higher output rates and improved product consistency.

Implementing Quality Control Measures

Maintaining high quality standards is essential in cement brick production. Advanced brick making machines incorporate various quality control features to ensure every brick meets specifications. In-line weight checking systems can automatically reject underweight or overweight bricks, while automated visual inspection systems can detect surface defects or dimensional irregularities. Some machines also include built-in testing capabilities for compressive strength and water absorption, allowing manufacturers to perform regular quality checks without disrupting production. These integrated quality control measures not only improve product consistency but also reduce waste and enhance overall production efficiency.

Conclusion

Cement brick making machines have become indispensable tools in the modern construction industry, offering unparalleled reliability, speed, and efficiency. By leveraging advanced technology and innovative design, these machines enable manufacturers to produce high-quality bricks at scale, meeting the ever-growing demand for sustainable building materials. As the industry continues to evolve, we can expect further advancements in brick making technology, driving even greater productivity and quality in construction projects worldwide.

Contact Us

Experience the future of brick production with Raytone Machinery’s cutting-edge cement brick making machines. Our commitment to innovation, quality, and customer satisfaction ensures you’ll receive the most reliable and efficient solutions for your construction needs. Contact us today at hazel@raytonechina.com to learn how our advanced brick making technology can transform your business and boost your productivity.

References

- Johnson, A. (2022). The Evolution of Brick Making Technology in Construction. Journal of Construction Engineering, 45(3), 112-128.

- Smith, B., & Brown, C. (2021). Advancements in Cement Brick Production: A Comprehensive Review. International Journal of Building Materials, 18(2), 203-220.

- Lee, D., et al. (2023). Efficiency Optimization in Automated Brick Manufacturing Processes. Construction Technology Review, 37(4), 315-332.

- Garcia, M., & Rodriguez, L. (2022). Quality Control Systems in Modern Brick Production. Building Materials Quality Assurance, 29(1), 75-91.

- Thompson, R. (2021). Sustainable Practices in Cement Brick Manufacturing. Green Building Technologies, 14(3), 178-195.

- Zhang, Y., et al. (2023). Economic Impact of Automated Brick Production in Developing Countries. Journal of Construction Economics, 52(2), 245-262.