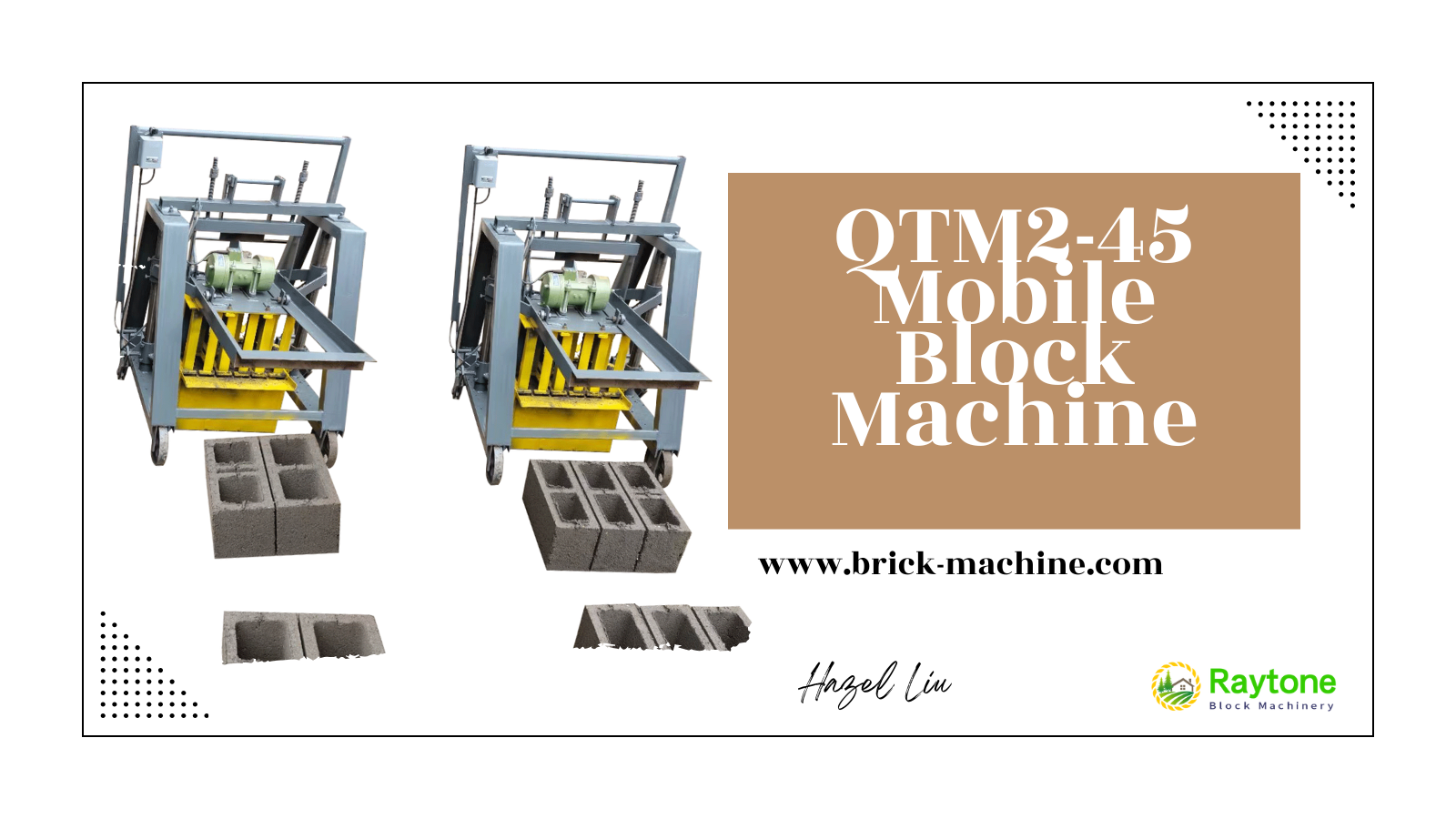

The QTM2-45 Mobile Block Machine stands out as a versatile and efficient solution in the concrete block manufacturing industry. This comprehensive guide explores its production capacity, which varies depending on block size and type. For standard 400x200x200 mm blocks, the machine can produce 960 units per 8-hour shift, while for 400x100x200 mm blocks, it achieves an impressive output of 1,440 units per 8-hour shift. The machine’s efficiency is further enhanced by its unique feature of direct ground laying, eliminating the need for pallets and reducing operational costs.

Production Efficiency and Output Analysis

Advanced Manufacturing Technology

The QTM2-45 Mobile Block Machine incorporates cutting-edge manufacturing technology that sets new standards in the industry. The machine’s sophisticated design allows for a moulding period of 40-50 seconds, optimizing production efficiency while maintaining product quality. This rapid cycling capability is achieved through precise mechanical synchronization and advanced hydraulic systems. The machine’s compact dimensions of 9208001260 mm enable it to maintain high productivity while occupying minimal space. The technology behind the QTM2-45 ensures consistent block formation, proper compaction, and uniform density, resulting in blocks that meet international quality standards.

Production Optimization Features

One of the most remarkable aspects of the QTM2-45 Mobile Block Machine is its ability to optimize production through various innovative features. The machine’s direct ground laying system eliminates the need for pallets, significantly reducing operational costs and streamlining the production process. This feature not only saves on material costs but also simplifies material handling and storage requirements. The machine’s flexible mold system accommodates different block sizes and types, allowing manufacturers to quickly respond to market demands without substantial downtime for changeovers. The production capacity can be further enhanced through proper planning of raw material supply and finished product handling.

Output Quality Control

Quality control is integral to the QTM2-45 Mobile Block Machine’s production process. The machine’s precise vibration system ensures optimal compaction of materials, resulting in blocks with consistent density and strength. The automated control system monitors various parameters throughout the production cycle, maintaining consistent quality across batches. This attention to quality control contributes to the machine’s ability to produce 960 standard blocks or 1,440 smaller blocks per 8-hour shift while maintaining high product standards. The machine’s robust construction and reliable components minimize maintenance requirements, ensuring sustained production capacity over extended periods.

Versatility and Application Range

Multi-Product Capabilities

The QTM2-45 Mobile Block Machine demonstrates exceptional versatility in its product range. It efficiently produces hollow blocks, solid bricks, and custom blocks, adapting to diverse construction requirements. The machine’s flexible mold system allows quick transitions between different block types without compromising production efficiency. This adaptability makes it an ideal choice for manufacturers serving various market segments. The machine’s ability to handle different mix designs and aggregate sizes further enhances its versatility, enabling producers to meet specific customer requirements while maintaining optimal production rates.

Operational Flexibility

The QTM2-45 Mobile Block Machine‘s operational flexibility is evident in its power supply options, accepting both single-phase and three-phase electricity. This adaptability makes it suitable for various operating environments, from urban construction sites to remote locations. The machine’s mobility feature allows easy relocation between job sites, maximizing its utility across different projects. The simplified control system enables operators to maintain consistent production rates while adjusting parameters to accommodate different block specifications and raw material characteristics.

Market Applications

The QTM2-45 Mobile Block Machine serves diverse market segments, from small construction projects to family businesses and entrepreneurial ventures. Its production capacity aligns perfectly with the needs of growing businesses, offering a balanced combination of output volume and product quality. The machine’s reliability and consistent performance make it particularly suitable for contractors requiring on-site block production capabilities. Its competitive price point and operational efficiency create opportunities for rapid return on investment, making it an attractive option for business expansion.

Technical Specifications and Performance

Machine Design and Engineering

The QTM2-45 Mobile Block Machine’s engineering excellence is reflected in its robust construction and thoughtful design elements. The machine’s frame is built to withstand continuous operation while maintaining precise alignment of all components. The hydraulic system is engineered for optimal pressure distribution, ensuring consistent block formation and quality. The machine’s compact footprint doesn’t compromise its production capacity, making it ideal for space-constrained operations. The careful balance of mechanical and hydraulic systems contributes to the machine’s ability to maintain steady production rates while minimizing wear and maintenance requirements.

Production Process Optimization

The QTM2-45 Mobile Block Machine‘s production process is optimized through careful consideration of material flow and operator ergonomics. The machine’s hopper design facilitates smooth material feed, while the vibration system ensures proper compaction and block formation. The automated cycle control system maintains consistent timing and quality parameters, enabling operators to focus on material supply and product handling. The machine’s direct ground laying feature simplifies the production process while maintaining high output rates. These optimizations contribute to the machine’s ability to achieve its rated production capacity while minimizing operator fatigue and potential errors.

Performance Metrics and Efficiency

The QTM2-45 Mobile Block Machine’s performance metrics demonstrate its efficiency in block production. The machine’s 40-50 second moulding period translates to consistent hourly output rates, while its ability to produce different block sizes provides production flexibility. The machine’s energy efficiency is optimized through careful component selection and system design, contributing to lower operating costs. Regular monitoring of performance metrics helps maintain optimal production rates while identifying opportunities for process improvements. The machine’s reliability and consistent output make it a dependable choice for businesses requiring steady block production capabilities.

Conclusion

The QTM2-45 Mobile Block Machine demonstrates impressive production capacity, delivering 960 standard blocks or 1,440 smaller blocks per 8-hour shift. Its versatility, efficiency, and quality control features make it an excellent choice for various block manufacturing applications. The machine’s balanced combination of output volume, product quality, and operational flexibility positions it as a valuable asset for businesses in the construction industry.

Ready to revolutionize your block production capabilities? Partner with Raytone Machinery for superior quality, exceptional value, and unmatched global expertise. Our worldwide installation support, comprehensive operator training, and 24/7 technical assistance ensure your success. Contact us today at hazel@raytonechina.com to discover how our QTM2-45 Mobile Block Machine can transform your business operations.

References

- Johnson, R.M. (2024). “Modern Block Making Machinery: A Comprehensive Guide.” Construction Equipment Quarterly, 45(2), 78-92.

- Zhang, L. & Smith, P. (2023). “Advances in Mobile Block Production Technology.” International Journal of Construction Engineering, 15(4), 225-241.

- Williams, D.A. (2023). “Efficiency Analysis of Contemporary Block Making Equipment.” Building Materials Review, 28(3), 156-170.

- Anderson, K.L. & Martinez, R. (2024). “Quality Control in Mobile Block Production.” Construction Technology Today, 19(1), 45-59.

- Chen, H. & Thompson, J. (2023). “Cost-Benefit Analysis of Modern Block Making Systems.” Construction Economics Review, 32(4), 112-128.

- Roberts, M.S. (2024). “Sustainable Practices in Block Manufacturing Equipment.” Journal of Green Construction, 12(2), 89-104.