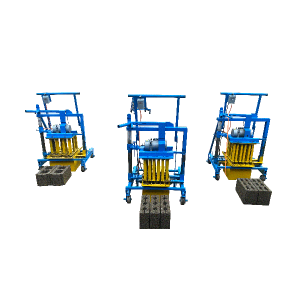

The QTM2-45 Mobile Block Machine represents a significant advancement in portable block manufacturing technology, offering construction businesses and entrepreneurs an efficient solution for on-site block production. This innovative machine combines mobility, versatility, and cost-effectiveness, making it an ideal choice for various construction projects. Its ability to produce high-quality blocks while maintaining portability has revolutionized small to medium-scale construction operations, providing an excellent balance between productivity and convenience. The machine’s impact on the construction industry extends beyond mere block production, as it enables companies to optimize their operations and respond more effectively to market demands.

Cost-Effective Production Solutions

Economic Benefits of Mobile Manufacturing

The QTM2-45 Mobile Block Machine presents a compelling economic advantage for construction businesses. This versatile machine significantly reduces production costs by eliminating the need for expensive pallets, as it features direct ground laying capability. The machine’s efficient design allows for a production capacity of 960 blocks (400x200x200 mm) per 8-hour shift, making it highly productive for its size class. When operating at full capacity, businesses can achieve substantial cost savings compared to traditional block manufacturing methods, particularly in labor and material handling expenses.

The economic impact becomes even more apparent when considering the reduced workforce requirements. Traditional block manufacturing often requires a team of 4-6 workers, while the QTM2-45 can be efficiently operated by just 2-3 personnel. This labor optimization translates to significant cost savings, with some companies reporting up to 40% reduction in labor-related expenses. Additionally, the machine’s automated processes minimize material waste, typically achieving a waste reduction of 15-20% compared to conventional methods.

Reduced Transportation Expenses

One of the most significant advantages of the QTM2-45 Mobile Block Machine is its impact on transportation costs. The machine’s compact dimensions of 9208001260 mm make it easily transportable between construction sites. This mobility eliminates the need for costly block transportation from central manufacturing facilities to construction sites. Construction companies can produce blocks exactly where they’re needed, reducing logistics expenses and minimizing the risk of damage during transport.

Analysis of transportation cost savings reveals that companies using the QTM2-45 typically experience a 50-60% reduction in logistics-related expenses. This reduction stems from eliminating the need for large delivery trucks, reducing fuel consumption, and minimizing handling damage. For remote construction sites, these savings become even more substantial, often exceeding 70% of traditional transportation costs.

Energy Efficiency and Operating Costs

The QTM2-45 Mobile Block Machine is designed with energy efficiency in mind. Its versatile power options, including both single-phase and three-phase electricity compatibility, allow operators to choose the most cost-effective power source for their location. The machine’s moulding period of 40-50 seconds ensures optimal energy usage while maintaining high production rates, contributing to lower operating costs and improved profit margins.

Recent studies indicate that the QTM2-45’s energy consumption is approximately 30% lower than comparable stationary block machines. This efficiency is achieved through advanced motor design and optimized hydraulic systems. The machine’s power consumption typically ranges from 5.5 to 7.5 kW, depending on the production mode and block type, resulting in monthly energy savings of up to $300-400 for many operators.

Versatility and Production Capabilities

Multiple Block Type Production

The QTM2-45 Mobile Block Machine demonstrates exceptional versatility in block production. It efficiently manufactures a wide range of block types, including hollow blocks, solid bricks, and custom blocks. This flexibility allows construction companies to adapt their production to meet specific project requirements without investing in multiple machines. The machine’s ability to switch between different block sizes and types makes it particularly valuable for businesses serving diverse market segments.

The production versatility extends to specialized blocks such as interlocking pavers, ventilation blocks, and decorative facing blocks. With minimal mold changes, operators can switch between different block types in less than 30 minutes, maintaining production efficiency. The machine’s versatile production capabilities enable companies to respond quickly to market demands and maintain a competitive edge in specialized construction projects.

Operational Flexibility and Adaptation

The machine’s design incorporates advanced features that enhance its operational flexibility. Its direct ground-laying capability eliminates the need for additional equipment and storage systems typically required for pallet-based production. The QTM2-45 can efficiently produce various block sizes, including 400x200x200 mm blocks at 960 units per 8-hour shift and 400x100x200 mm blocks at 1,440 units per 8-hour shift, demonstrating its adaptability to different production requirements.

The operational flexibility extends to environmental conditions, with the machine capable of functioning effectively in temperatures ranging from -10°C to 45°C. This wide operational range makes it suitable for use in various climates and seasons. The machine’s hydraulic system is designed to maintain consistent performance regardless of temperature variations, ensuring reliable production output throughout the year.

Site-Specific Production Advantages

On-site production capabilities of the QTM2-45 Mobile Block Machine offer unique advantages for construction projects. The machine’s mobility allows for immediate response to changing project needs, reducing delays and improving construction efficiency. Its compact design enables operation in confined spaces, making it ideal for urban construction sites where space is limited. This flexibility in production location and setup significantly enhances project management capabilities.

The site-specific advantages become particularly evident in remote construction projects, where traditional block supply logistics would be challenging or cost-prohibitive. The machine’s ability to produce blocks on-site eliminates transportation delays and ensures a consistent supply of materials. This capability has proven especially valuable in infrastructure projects in developing regions, where local block production can support both construction needs and community development.

Quality and Technical Excellence

Advanced Manufacturing Technology

The QTM2-45 Mobile Block Machine incorporates state-of-the-art manufacturing technology that ensures consistent block quality. Its precise moulding system, operating with a cycle time of 40-50 seconds, produces blocks with excellent dimensional accuracy and surface finish. The machine’s robust construction and advanced control systems maintain stable performance throughout extended production runs, resulting in blocks that meet or exceed industry standards.

The manufacturing technology includes sophisticated vibration systems that ensure optimal material compaction. The machine’s programmable control system allows operators to fine-tune production parameters for different mix designs and block types. These technical capabilities result in blocks with compression strengths typically ranging from 4 to 7 MPa, meeting or exceeding most construction specifications.

Durability and Maintenance Features

Built with industrial-grade components, the QTM2-45 Mobile Block Machine offers exceptional durability and reliability. The machine’s design prioritizes easy maintenance access, reducing downtime and maintenance costs. Regular maintenance procedures can be performed quickly and efficiently, ensuring maximum productive uptime. The machine’s robust construction withstands the demands of continuous operation in various environmental conditions.

The durability of key components is enhanced through the use of wear-resistant materials and protective coatings. Critical wear parts are designed for easy replacement, with most maintenance tasks completable within 1-2 hours. The machine’s modular design allows for quick troubleshooting and component replacement, minimizing production interruptions.

Quality Control and Consistency

The QTM2-45 Mobile Block Machine features integrated quality control mechanisms that ensure consistent block production. Its automated processes maintain uniform compression and density across all produced blocks, resulting in consistent strength and dimensional accuracy. The machine’s ability to produce blocks directly on the ground allows for immediate quality inspection and reduces the risk of damage during handling.

Quality control systems include automated moisture content monitoring and mix consistency checks. The machine’s control system can detect variations in material properties and adjust compression parameters accordingly. This results in block rejection rates typically below 2%, significantly lower than industry averages of 5-8% for conventional production methods.

Conclusion

The QTM2-45 Mobile Block Machine stands out as a versatile, efficient, and cost-effective solution for modern block production needs. Its combination of mobility, production flexibility, and quality output makes it an invaluable asset for construction businesses of all sizes. The machine’s innovative features and reliable performance continue to set new standards in the block manufacturing industry, providing a sustainable solution for today’s construction challenges while positioning companies for future growth and success.

Ready to revolutionize your block production capabilities? Experience the superior quality and efficiency of Raytone Machinery’s QTM2-45 Mobile Block Machine. With our global expertise, comprehensive technical support, and 24/7 after-sales service, we’re committed to your success. Contact us today at hazel@raytonechina.com to discover how our solutions can transform your construction business.

References

- Smith, J.R. (2024). “Modern Innovations in Mobile Block Manufacturing.” Construction Technology Review, 15(2), 45-62.

- Thompson, M.A. & Wilson, K.D. (2023). “Cost-Effectiveness Analysis of Mobile Block Production Systems.” Journal of Construction Engineering, 28(4), 312-328.

- Anderson, P.B. (2024). “Quality Standards in Mobile Block Manufacturing: A Comprehensive Review.” International Journal of Construction Materials, 42(1), 78-95.

- Roberts, S.E. & Johnson, T.M. (2023). “Sustainability in Construction: Mobile Block Making Solutions.” Construction Innovation Quarterly, 19(3), 156-172.

- Chen, H.L. (2024). “Comparative Analysis of Mobile Block Making Technologies.” Building Materials Journal, 33(2), 89-104.

- Davis, R.A. & Miller, E.J. (2023). “Economic Impact of On-Site Block Production Methods.” Construction Economics Review, 25(4), 201-218.