In today’s competitive brick-making industry, choosing the right pallet for your block machine can significantly impact production efficiency, product quality, and long-term costs. While traditional materials like wood and plastic have been widely used for decades, a new and more advanced material has entered the market — GMT (Glass Mat Reinforced Thermoplastic) brick pallets.

GMT pallets represent the next generation of block machine pallet solutions, offering superior strength, water resistance, and eco-friendliness. As manufacturers worldwide upgrade their concrete block production lines, GMT pallets are fast becoming the preferred choice for those seeking durability and sustainability without compromising on cost-effectiveness.

What Sets GMT Brick Pallets Apart?

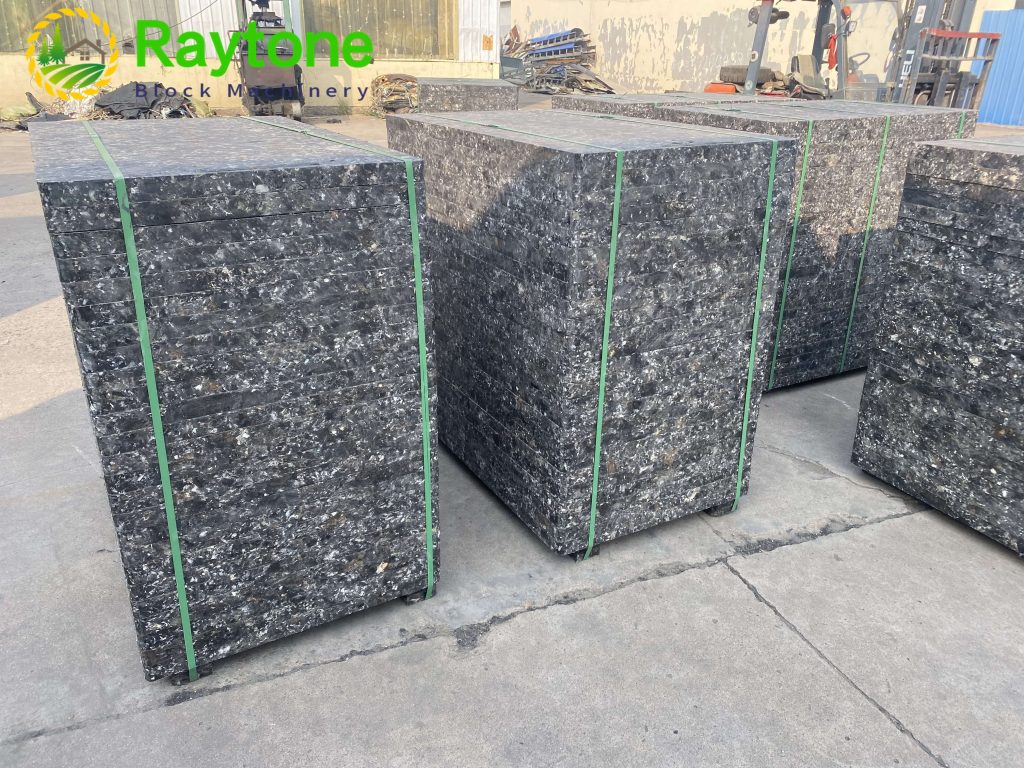

The secret behind the exceptional performance of GMT pallets lies in their innovative composition and manufacturing process. These pallets are produced by combining glass fiber mats with thermoplastic resin, then molding them under extremely high pressure — often up to 3000 tons. The result is a dense, non-porous material with a standard density of 1200 kg/m³, engineered specifically for heavy-duty block-making operations.

Unlike wooden pallets that absorb water and deform over time, or plastic pallets that may crack in extreme conditions, GMT brick pallets maintain their structural integrity even under constant vibration, compression, and moisture exposure. Their ability to withstand these harsh production conditions makes them a perfect match for fully automatic brick machines and semi-automatic block machines alike.

Key Advantages of GMT Brick Pallets

1. Exceptional Durability and Longevity

Durability is a defining feature of GMT pallets. With a service life of 8–10 years, they far exceed the typical lifespan of wooden pallets (1–2 years) and plastic pallets (around 5–6 years). Their glass fiber reinforcement allows them to carry heavy block loads without bending or cracking, even during long-term use in high-capacity cement block production lines.

For factories operating automatic hydraulic block machines, this durability ensures smooth operation and consistent block molding — reducing downtime and the need for frequent pallet replacement.

2. Superior Moisture and Temperature Resistance

Moisture is one of the biggest threats to block machine pallets, as it leads to swelling, warping, and microbial growth. GMT pallets solve this problem completely. Their non-absorbent surface prevents water penetration, eliminating mold and rot issues common in wood or bamboo pallets.

Furthermore, GMT pallets maintain their strength across a wide range of temperatures. Whether you’re running your brick machine in a humid tropical environment or a cold climate with freeze-thaw cycles, GMT pallets stay stable and reliable — ensuring consistent brick and paver production all year round.

3. Cost-Effectiveness Over Time

At first glance, wooden pallets appear cheaper, but their short lifespan means frequent replacements — a hidden cost that quickly adds up. Plastic pallets last longer but come with a high upfront price tag. GMT pallets strike the perfect balance between initial investment and long-term savings.

Their extended service life, combined with lower maintenance and replacement costs, results in significant cost reductions over the pallet’s lifetime. Additionally, their lightweight structure makes handling and transportation easier, lowering logistics expenses for brick manufacturers.

4. Eco-Friendly and Sustainable Design

Modern block-making operations are increasingly focused on sustainability and green manufacturing. GMT brick pallets fully support this mission. They are often made using recycled industrial materials, helping reduce waste and minimize environmental impact.

Unlike wooden pallets that contribute to deforestation or PVC plastic pallets derived from petroleum-based materials, GMT pallets are a sustainable, eco-conscious choice. Their long service life further minimizes resource consumption and landfill waste, aligning with global sustainability standards in the construction machinery sector.

Comparing GMT, Wooden, and Plastic Pallets

| Feature | Wooden Pallets | Plastic Pallets | GMT Brick Pallets |

|---|---|---|---|

| Lifespan | 1–2 years | 5–6 years | 8–10 years |

| Moisture Resistance | Poor | Moderate | Excellent |

| Durability Under Load | Weak | Moderate | Very Strong |

| Temperature Resistance | Poor | Average | Excellent |

| Environmental Impact | High (deforestation) | Moderate (petroleum-based) | Low (recycled materials) |

| Cost-Effectiveness | Low | Moderate | High |

From every perspective — longevity, performance, environmental responsibility, and cost — GMT clearly outshines the traditional alternatives. For manufacturers operating concrete block machines, the choice is straightforward: GMT is the future of block production efficiency.

Performance in Real-World Block-Making Environments

In modern concrete block factories, pallets must withstand continuous vibration, compression, and exposure to wet cement. GMT brick pallets excel under these demanding conditions. Their smooth surface ensures easy demolding and consistent brick dimensions, while their high impact resistance prevents edge chipping and cracking during repeated use.

Whether used with QT4-18, QT6-15, or QT10-15 automatic block machines, GMT pallets maintain their performance and precision over thousands of cycles. This stability helps manufacturers achieve higher output rates, reduced waste, and improved product uniformity.

Adaptability to Various Block Machine Models

GMT brick pallets are compatible with a wide range of block machine types, including:

-

Fully automatic hydraulic block machines

-

Semi-automatic concrete brick machines

-

Manual block-making systems

Their lightweight yet high-strength design makes them easy to handle, load, and align, helping operators save time and improve efficiency. Whether producing hollow blocks, solid bricks, paving stones, or curbstones, GMT pallets deliver dependable performance across all block types.

Why GMT Pallets Are the Future of Block Machine Operations

The shift from wooden and plastic pallets to GMT is more than a material upgrade — it’s a technological evolution in the brick machine industry. With their combination of strength, sustainability, and cost efficiency, GMT pallets offer tangible benefits that go far beyond durability.

As more manufacturers prioritize quality control and eco-friendly production, GMT brick pallets have become the industry benchmark for reliable and sustainable pallet solutions. When paired with high-performance equipment like Raytone Machinery’s automatic block machines, they help create a complete, efficient, and environmentally responsible concrete block production system.

Conclusion

When evaluating pallet options for your block-making operation, consider not just the upfront cost, but the long-term performance and environmental impact. GMT brick pallets deliver an unmatched balance of strength, moisture resistance, and sustainability — lasting up to 10 years with minimal maintenance.

They outperform traditional wooden and plastic pallets in every major category, making them the smartest investment for manufacturers seeking to improve efficiency and profitability in the concrete block industry.

Contact Raytone Machinery

Upgrade your block machine pallets today with GMT technology from Raytone Machinery, a trusted manufacturer of brick-making machines, concrete block machines, and GMT pallets.

📧 Email: hazel@raytonechina.com

Discover how GMT pallets can transform your production efficiency and help you lead in sustainable brick manufacturing.