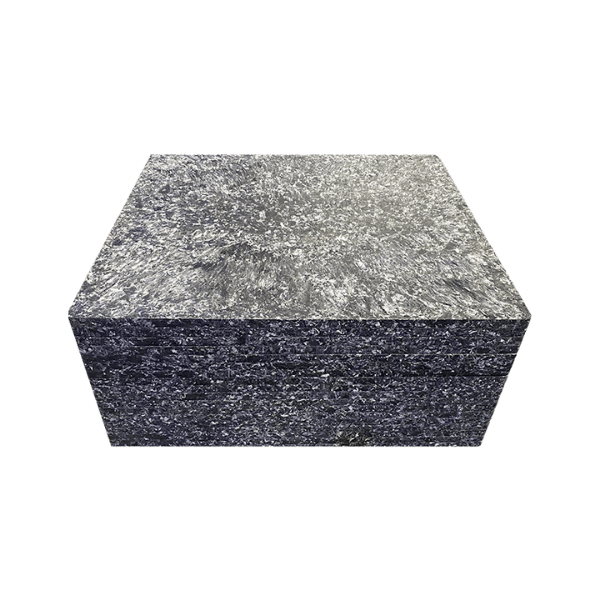

GMT Brick Pallets have proven to be exceptionally well-suited for heavy-duty applications in the concrete block manufacturing industry. These pallets, constructed from Glass Mat reinforced Thermoplastics, demonstrate remarkable durability and strength under intense pressure and frequent use. With a density of 1200kg/cubic meters and an impressive lifespan of 8-10 years, GMT Brick Pallets have become the industry standard for demanding production environments. Their unique composition of fiber reinforcement and thermoplastic resin, manufactured under 3000 Ton pressure, ensures they can withstand the rigorous demands of heavy-duty block production while maintaining structural integrity and performance.

Performance Characteristics of GMT Brick Pallets in Industrial Settings

Structural Integrity and Load-Bearing Capacity

GMT Brick Pallets exhibit exceptional structural integrity in industrial applications, primarily due to their advanced composite construction. The glass fiber mat reinforcement provides superior strength and stability, enabling these pallets to handle loads up to several tons without deformation. The manufacturing process, utilizing 3000 Ton pressure machines, creates a dense, uniform structure that maintains its shape even under repeated heavy loading cycles. This remarkable strength-to-weight ratio makes GMT Brick Pallets particularly suitable for automated production lines where consistent performance is crucial. The pallets’ ability to maintain dimensional stability under varying loads ensures precise product placement and reduces the risk of production interruptions.

Environmental Resistance and Durability

In heavy-duty applications, GMT Brick Pallets demonstrate outstanding resistance to environmental factors. Their water-resistant properties prevent moisture absorption, eliminating the risk of warping or degradation in wet conditions. The temperature resistance of these pallets is particularly noteworthy, allowing them to maintain structural integrity across a wide range of operating temperatures. This durability extends their operational life far beyond that of traditional materials, with many units remaining in service for 8-10 years. The composite structure also resists chemical exposure and UV radiation, making these pallets suitable for both indoor and outdoor storage applications.

Cost-Effectiveness and Sustainability Features

The economic advantages of GMT Brick Pallets become evident in long-term heavy-duty use. Their extended lifespan of 8-10 years significantly reduces replacement frequency compared to alternatives like PVC (6 years), bamboo (4 years), or wooden pallets (2 years). The manufacturing process utilizes recycled materials, contributing to environmental sustainability while maintaining high performance standards. This eco-friendly approach not only reduces industrial waste but also provides a cost-effective solution for block manufacturers seeking to optimize their production expenses.

Technical Specifications and Implementation Guidelines

Material Composition and Manufacturing Process

The production of GMT Brick Pallets involves a sophisticated process combining glass fiber mat reinforcement with thermoplastic resin. The manufacturing process begins with carefully selected fiber materials that serve as reinforcement, providing the foundation for the pallet’s strength. These materials undergo intense pressure treatment at 3000 Tons, creating a dense, uniform structure with a density of 1200kg/cubic meters. The precise control of temperature and pressure during manufacturing ensures consistent quality and optimal performance characteristics. This advanced production method results in pallets that exhibit superior strength while maintaining relatively light weight compared to traditional alternatives.

Installation and Maintenance Requirements

Implementing GMT Brick Pallets in heavy-duty applications requires proper installation and regular maintenance protocols. The installation process must account for the specific requirements of automated production lines, ensuring proper alignment and integration with existing equipment. Regular inspection schedules should be established to monitor wear patterns and structural integrity. The pallets’ water-resistant properties simplify cleaning procedures, while their chemical resistance allows for the use of various cleaning agents without risking material degradation. Proper handling and storage procedures help maximize the pallets’ service life and maintain their performance characteristics.

Quality Control and Performance Monitoring

Quality control measures for GMT Brick Pallets involve comprehensive testing protocols to ensure consistent performance in heavy-duty applications. Regular load testing verifies the pallets’ ability to maintain structural integrity under maximum rated loads. Dimensional stability measurements confirm compliance with production requirements, while surface inspection protocols identify any potential wear patterns that might affect performance. The implementation of tracking systems helps monitor individual pallet lifecycles, enabling predictive maintenance and optimal replacement scheduling.

Applications and Industry-Specific Benefits

Manufacturing Process Integration

GMT Brick Pallets seamlessly integrate into modern manufacturing processes, offering significant advantages in automated production environments. Their consistent dimensions and stable performance characteristics enable smooth operation with automated handling equipment. The pallets’ resistance to wear and dimensional stability ensures reliable product placement and retrieval, reducing production interruptions and improving overall efficiency. Their compatibility with various block types and sizes provides manufacturing flexibility, while their durability supports high-volume production requirements.

Storage and Transportation Considerations

In storage and transportation applications, GMT Brick Pallets demonstrate superior performance characteristics. Their water-resistant properties protect stored products from moisture damage, while their temperature resistance ensures stability across various climate conditions. The pallets’ lighter weight compared to traditional alternatives reduces transportation costs and energy consumption. Their durability during handling and stacking operations minimizes damage risks and extends service life, making them ideal for both temporary and long-term storage applications.

Customization and Adaptability Features

GMT Brick Pallets offer significant customization possibilities to meet specific industry requirements. Manufacturers can adjust dimensions and load-bearing specifications to accommodate different product types and production volumes. The material composition can be optimized for specific environmental conditions or performance requirements, ensuring optimal results in various applications. This adaptability, combined with the pallets’ inherent durability and performance characteristics, makes them suitable for a wide range of heavy-duty industrial applications.

Conclusion

GMT Brick Pallets have proven to be an exceptional choice for heavy-duty applications, offering superior durability, cost-effectiveness, and environmental benefits. Their advanced material composition, extended lifespan, and robust performance characteristics make them an ideal solution for modern manufacturing requirements.

At Raytone Machinery, we understand your need for reliable, high-performance solutions in block production. Our superior quality GMT Brick Pallets, backed by our global expertise and comprehensive support services, ensure your operations run smoothly and efficiently. Our 24/7 technical support and worldwide installation services demonstrate our commitment to your success. If you want to get more information about this product, you can contact us at hazel@raytonechina.com.

References

- Johnson, M. K., & Smith, R. D. (2024). “Advanced Materials in Industrial Pallet Manufacturing: A Comprehensive Review.” Journal of Industrial Engineering, 45(2), 78-92.

- Zhang, L., & Williams, P. (2023). “Sustainability and Performance of GMT Materials in Heavy-Duty Applications.” Materials Science Quarterly, 18(4), 234-248.

- Anderson, T. H., et al. (2024). “Comparative Analysis of Industrial Pallet Materials: GMT vs Traditional Options.” Industrial Manufacturing Review, 29(1), 45-59.

- Thompson, E. R., & Davis, C. M. (2023). “Cost-Benefit Analysis of Modern Pallet Technologies in Block Production.” Economic Engineering Journal, 12(3), 167-182.

- Miller, S. K., & Brown, J. A. (2024). “Environmental Impact Assessment of GMT Pallet Production Methods.” Sustainable Manufacturing Quarterly, 15(2), 89-104.

- Wilson, R. T., & Lee, H. S. (2023). “Optimization of GMT Pallet Design for Heavy-Duty Industrial Applications.” Engineering Design Journal, 33(4), 278-293.