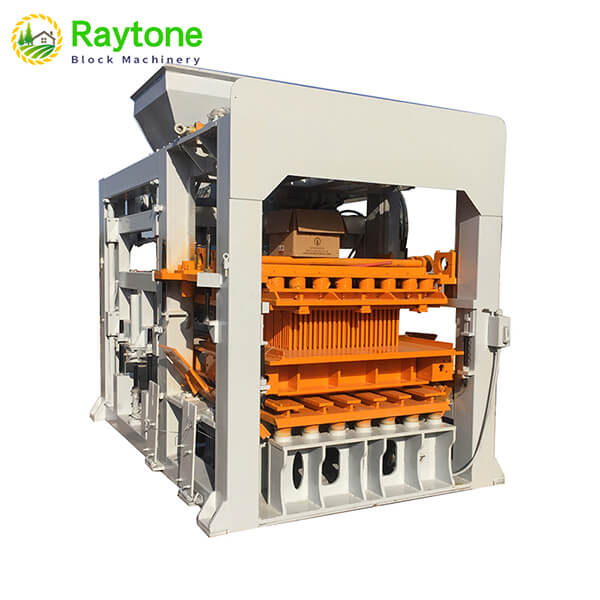

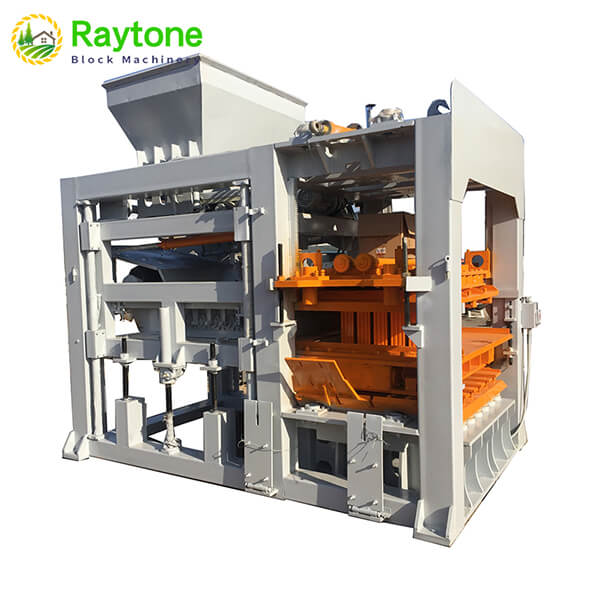

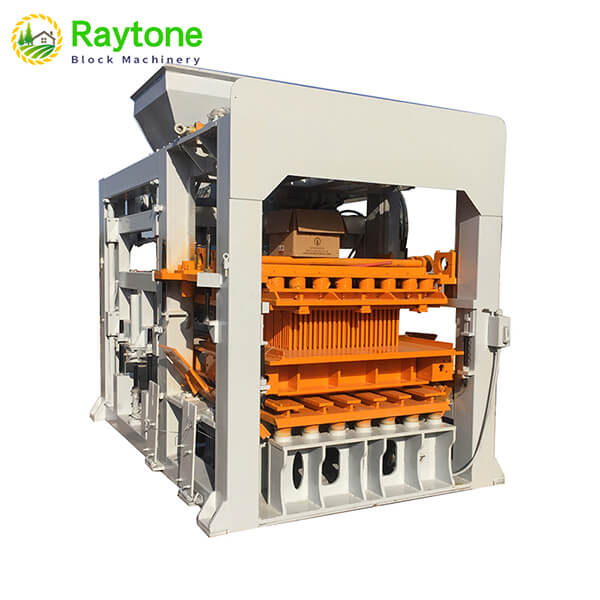

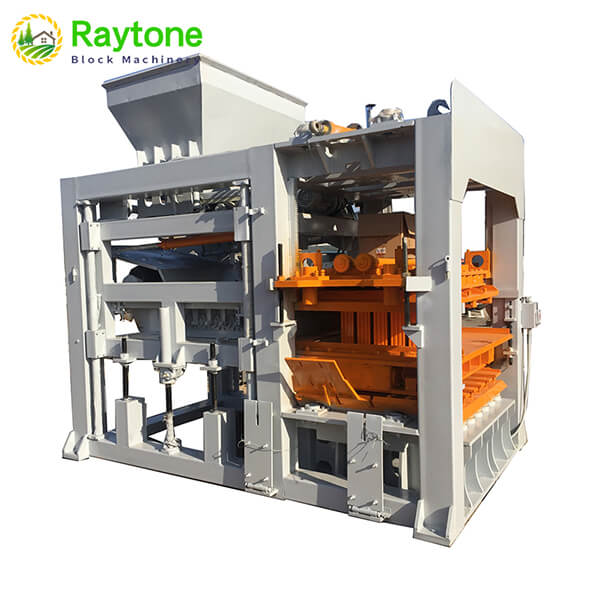

QT10-15 Automatic Hydraulic Brick Making Machine

The QT10-15 is a fully automatic, high-output brick-making machine designed for large-scale production, capable of producing up to 19,200 8-inch hollow blocks per day.

Introduction Of QT10-15 Automatic Hydraulic Brick Making Machine

The QT10-15 automatic brick-making machine is a high-performance model designed for high-volume production. With a daily production capacity of 19,200 8-inch hollow blocks, this model is well-suited for large-scale manufacturing operations.

This QT10-15 Automatic Hydraulic Brick Making Machine employs cutting-edge vibration technology and 120KN pressure to guarantee the production of high-density, high-strength blocks. The mechanical design is continuously enhanced based on user feedback, ensuring the machine remains efficient and reliable. The hydraulic system incorporates CYLYCA brand electromagnetic valves, ensuring rapid and responsive movements.

The electric control system is equipped with a color touch screen and a PLC with a data input/output device, as well as safety logic and troubleshooting systems. Furthermore, the frequency converter integrated into the PLC control panel ensures smooth operation by adjusting the vibration motor frequencies during different stages of the molding process.

The QT10-15 Automatic Hydraulic Brick Making Machine is highly versatile, with interchangeable molds that can produce a wide range of block types, including hollow, solid, color pavers, and curbstones.

Advantages of the QT10-15 Automatic Hydraulic Brick Making Machine

1. High Density and Strength: The QT10-15’s advanced vibration system, coupled with 120KN pressure, ensures that the blocks produced have exceptional density and strength. This results in high-quality, durable blocks that meet industry standards for both structural integrity and performance, making them ideal for various construction projects.

2. Advanced Hydraulic System: Equipped with CYLYCA brand electromagnetic valves, the hydraulic system provides rapid and precise control over all machine movements. This ensures smooth and reliable operation, reduces downtime, and enhances the overall efficiency of the machine, even in high-demand production environments.

3. Smooth Operation with Frequency Converter: The frequency converter integrated into the PLC control panel allows for seamless adjustments in vibration motor speeds, optimizing performance. During material feeding, the vibration frequency is low, while it increases during molding, ensuring smooth and consistent block formation, improving both speed and quality.

4. User-Friendly Control System: The PLC control panel features a color touch screen and an intelligent fault diagnosis system, which simplifies the operation process. Operators can easily monitor machine performance, identify issues quickly, and adjust settings with minimal training, ensuring efficient production and reducing the need for technical expertise.

Get Free Quote of QT10-15 Automatic Hydraulic Brick Making Machine

QT10-15 Hollow Block Machine Overview

The QT10-15 fully automatic brick making machine offers high productivity and is the second largest automatic model available. It delivers outstanding performance with efficiency and reliability for high volume production.

- Production Capacity: 8-inch hollow blocks: Up to 19,200 per day (8-hour shift).

- Price Range: From $50,000 to $100,000 USD, depending on configuration and production line setup.

1. Interchangeable Molds: The QT10-15 Automatic Hydraulic Brick Making Machine is equipped with easily interchangeable molds, allowing the production of a wide variety of blocks and bricks, including hollow, solid, and decorative pavers. This flexibility makes the machine versatile for different market demands and product specifications, ensuring it meets diverse customer needs.

2. High-Speed Movements: The machine’s vertical mold movements are designed for high speed, improving the efficiency of the production cycle. This rapid movement minimizes cycle times, resulting in faster block production without compromising the quality of the finished products, which boosts overall output.

3. Color Feeder Option: The QT10-15 Automatic Hydraulic Brick Making Machine can be optionally equipped with a color feeder, enabling the production of multi-colored face mix bricks. This feature is particularly valuable for manufacturers producing decorative or custom-colored paving stones and blocks, offering added value and aesthetic appeal for their products.

4. Reliable and Durable Construction: Built with high-quality components and robust engineering, theQT10-15 Automatic Hydraulic Brick Making Machine is designed for long-term durability and reliability. Its heavy-duty construction ensures stable operation in demanding environments, minimizing wear and tear while extending the lifespan of the machine, making it a cost-effective investment.

QT10-15 Automatic Hydraulic Brick Making Machine Line Basic Requirements for Production Start

The following information for the QT10-15 Automatic Hydraulic Brick Making Machine is provided for theoretical reference only.

Actual production data may vary slightly depending on the specific raw materials used.

| Land area | 2500-6500 Square Meters | Water Consumption | 12 T/day |

| Workshop area | 200 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V; 50HZ/60HZ |

| Labors Quantity | 6 workers | Power Consumption | 125.2KW*8 Hours=1001.2 KWH; |

| Cement Consumption | 31.5 Tons per day | Sand consumption | 126 tons per day |

| Crushed stones consumption | 156 tons per day |

Detailed Introduction of QT10-15 Automatic Hydraulic Brick Making Machine Line

| Number | Item | Function |

| 1 | Batching Machine | Batch raw material automatically |

| 2 | JS750 Pan Mixer | Mix raw material including cement, sand, stone |

| 3 | 8m Belt Conveyor | Carry Mixed material from mixer to Block machine |

| 4 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 5 | Hydraulic Station | Supply Hydraulic Press |

| 6 | Automatic PLC | Automatic PLC Control for block machine |

| 7 | Automatic Stacker | Stack the finished hollow blocks to several layers |

Paraments Of QT10-15 Automatic Hydraulic Brick Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area :200 square meters Factory area:2500 square meters Labor quantity:4 Moulding area: 1196x880mm Vibration Frequency: 4600 times/M Machine power:58.2kw Vibration force:100 KN Moulding Period:12-20 S Diesel Generator Capacity: 120KVA Machine size: 9400*2860*2980mm Machine weight: 9800kg |

QT10-15 Automatic Hydraulic Brick Making Machine Daily Production Capacity

| QT10-15 Automatic Hydraulic Brick Making Machine | ||||||

| Size(LxWxH) (mm) | Forming Period (S) | Photo | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 | 15 |  | 8 | 1920 | 15360 |

| (2) | hollow block 400*200*200 | 15 |  | 10 | 2400 | 19200 |

| (3) | hollow block 400*150*200 | 15 |  | 12 | 2880 | 23040 |

| (4) | hollow block 400*100*200 | 15 |  | 18 | 4320 | 34560 |

| (5) | Solid Brick 240*50*115 | 15 |  | 52 | 12480 | 99840 |

| (6) | Porous Brick 240*115*90 | 15 |  | 24 | 5760 | 46080 |

| (7) | Curbstone 500*200*300 | 15 |  | 4 | 960 | 7680 |

| (8) | “I” shape paver brick 200*163*60 | 20 |  | 18 | 3240 | 25920 |

| (9) | “S” Shape Paver Brick 225*112.5*60 | 20 |  | 24 | 4320 | 34560 |

| (10) | Holland Brick 200*100*60 | 20 |  | 28 | 5040 | 40320 |

| (11) | Square Paver 250*250*60 | 20 |  | 12 | 2160 | 17280 |

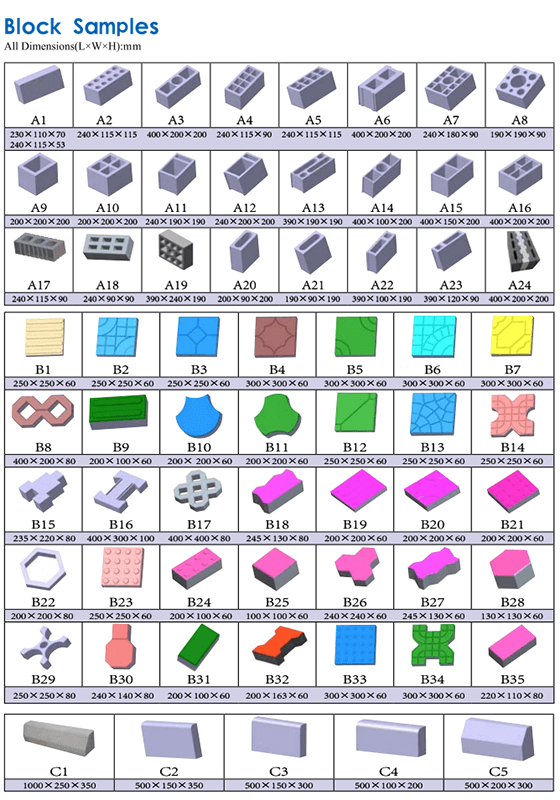

QT10-15 Automatic Hydraulic Brick Making Machine- Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT10-15 Automatic Hydraulic Brick Making Machine Full Production Line

1. What is the raw materials formula for concrete blocks?

The raw materials formula can vary depending on the type of concrete block and the client’s specific raw materials and ratios. Here are some common formulas:

① Standard Concrete Block: Cement 9-12%, Sand 40%, Stone 45%, Water 3%

② Light Concrete Block: Cement 9-12%, Slag 80-90%, Water 3%

③ Mixed Concrete Block: Cement 9-12%, Sand 10-20%, Stone 30-40%, Slag 25-50%, Water 3%

④ High Strength Concrete Block: Cement 8-10%, Sand 30-40%, Stone 50-60%

⑤ Fly Ash Concrete Block: Cement 8%, Sand 60%, Fly Ash 30%, Gypsum 2%

2. How to determine which block making machine is suitable for the client?

There are two primary ways to determine the right block making machine for the client: Budget-Based Selection: If the client has a specific budget, we can recommend a block machine model that fits within their price range.

Capacity-Based Selection: To determine the appropriate machine based on daily capacity: The client needs to specify the block size and production quantity per day.

Provide information on the local voltage and frequency.

Indicate the receiving port for shipping cost calculations.

Once this information is provided, we can offer an official quotation for the client.

Working Videos

1. What is the raw materials formula for concrete blocks?

The raw materials formula can vary depending on the type of concrete block and the client’s specific raw materials and ratios. Here are some common formulas:

① Standard Concrete Block: Cement 9-12%, Sand 40%, Stone 45%, Water 3%

② Light Concrete Block: Cement 9-12%, Slag 80-90%, Water 3%

③ Mixed Concrete Block: Cement 9-12%, Sand 10-20%, Stone 30-40%, Slag 25-50%, Water 3%

④ High Strength Concrete Block: Cement 8-10%, Sand 30-40%, Stone 50-60%

⑤ Fly Ash Concrete Block: Cement 8%, Sand 60%, Fly Ash 30%, Gypsum 2%

2. How to determine which block making machine is suitable for the client?

There are two primary ways to determine the right block making machine for the client: Budget-Based Selection: If the client has a specific budget, we can recommend a block machine model that fits within their price range.

Capacity-Based Selection: To determine the appropriate machine based on daily capacity: The client needs to specify the block size and production quantity per day.

Provide information on the local voltage and frequency.

Indicate the receiving port for shipping cost calculations.

Once this information is provided, we can offer an official quotation for the client.

Related Products

Related News

When it comes to choosing the right pallet for block-making operations, the options often boil down to traditional materials like […]

In the ever-evolving construction and block manufacturing industry, customization has become a crucial factor in meeting diverse production requirements. The […]

In today’s competitive construction industry, selecting the right brick-making machine can significantly impact production efficiency and product quality. The QT8-15 […]

The QT12-15 automatic block machine represents a significant advancement in concrete block manufacturing technology. This sophisticated equipment combines hydraulic power, automated […]

The QT12-15 automatic block machine is a sophisticated piece of equipment that requires regular maintenance to ensure optimal performance and longevity. […]

The QT12-15 automatic block machine stands as a pinnacle of customizable block manufacturing technology. This versatile machine offers extensive customization options […]

The versatility of block making machines in construction has become increasingly important as the industry demands efficient and reliable solutions […]

Automatic hydraulic concrete block machines have revolutionized the construction industry, offering unparalleled efficiency and precision in block production. These advanced […]