When it comes to choosing the right pallet for block-making operations, the options often boil down to traditional materials like wood and plastic or innovative alternatives like GMT (Glass Mat reinforced Thermoplastics). GMT brick pallets stand out due to their unique composition – fiber as a reinforcing material combined with thermoplastic resin, molded under intense heat and pressure. Unlike wooden pallets, which degrade quickly, or plastic pallets, which can be costly and less eco-friendly, GMT offers a superior balance of durability, cost-efficiency, and environmental benefits. With a lifespan of up to 10 years, water resistance, and lightweight design, GMT surpasses traditional options, making it an ideal choice for modern block machine operations.

Understanding the Core Advantages of GMT Brick Pallets

GMT brick pallets have revolutionized the block-making industry by offering a robust, sustainable, and cost-effective alternative to conventional pallet materials. To appreciate their value, it’s essential to explore their composition, performance, and environmental impact in detail.

What Makes GMT Brick Pallets Unique?

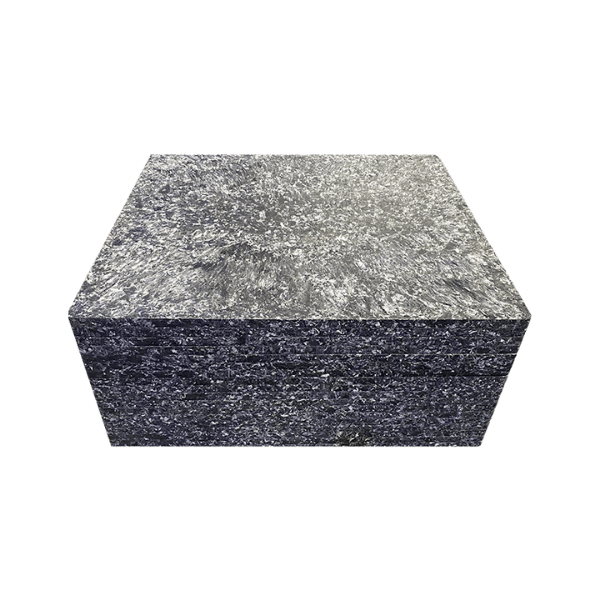

The foundation of a GMT brick pallet lies in its innovative construction. These pallets are crafted from a composite of glass fiber mats and thermoplastic resin, fused together using high-pressure machinery – often under forces as significant as 3000 tons. This process results in a material with a density of 1200 kg per cubic meter, making it both sturdy and lightweight. Unlike wooden pallets, which are prone to splintering, or plastic pallets, which may crack under extreme conditions, GMT pallets are engineered to withstand the rigors of block machine operations, including exposure to moisture and temperature fluctuations.

Performance Benefits in Block Machine Operations

When it comes to performance, GMT brick pallets excel in several key areas. Their water-resistant nature ensures they remain intact even in damp environments, a common challenge in block-making facilities. Additionally, their ability to endure temperature extremes makes them suitable for use in diverse climates. Compared to traditional wooden pallets, which may warp or rot, or plastic pallets, which can become brittle, GMT pallets maintain structural integrity over time. This durability translates to a lifespan of 8 to 10 years, far surpassing the 2-year average for wooden pallets and the 6-year average for plastic alternatives, making them a reliable choice for block machine pallets.

Environmental Impact and Sustainability

One of the most compelling advantages of GMT brick pallets is their contribution to sustainability. These pallets are often manufactured using recycled materials, including industrial leftovers, which reduces waste and minimizes the demand for virgin resources. This eco-friendly approach sets them apart from plastic pallets, which are typically derived from petroleum-based sources, and wooden pallets, which contribute to deforestation. By choosing GMT, block-making operations can align with global sustainability goals, reduce their environmental footprint, and appeal to environmentally conscious stakeholders, all while benefiting from a high-performing brick machine pallet.

Comparing GMT Brick Pallets to Traditional Pallet Options

To make an informed decision about pallet materials, it’s crucial to compare GMT brick pallets directly with their traditional counterparts – wooden and plastic pallets. Each material has its strengths and weaknesses, but GMT consistently emerges as the most balanced and forward-thinking option for block-making applications.

Lifespan and Durability Comparison

Durability is a critical factor in determining the value of a pallet, especially in high-intensity block machine environments. GMT brick pallets lead the pack with a lifespan of 8 to 10 years, thanks to their resistance to moisture, temperature changes, and physical wear. In contrast, wooden pallets typically last only 2 years before succumbing to rot, splintering, or insect damage. Plastic pallets fare better, with an average lifespan of 6 years, but they are prone to cracking under heavy loads or extreme cold. For operations seeking a long-lasting block machine pallet, GMT offers unmatched resilience and reliability.

Cost-Effectiveness Across Materials

While initial costs are an important consideration, the true value of a pallet lies in its long-term cost-effectiveness. Plastic pallets, often the most expensive upfront, can strain budgets, especially for large-scale block-making operations. Wooden pallets, while cheaper initially, require frequent replacements due to their short lifespan, driving up costs over time. GMT brick pallets strike an optimal balance, offering a moderate initial investment paired with exceptional longevity. When compared to bamboo pallets, which are slightly more expensive and last only 4 years, GMT emerges as the most economical choice for a brick machine pallet, delivering superior performance without breaking the bank.

Practical Applications in Block-Making

The practical advantages of GMT brick pallets become evident in real-world block-making scenarios. Their lightweight design – owing to a density of 1200 kg per cubic meter – makes them easy to handle, reducing labor fatigue and improving operational efficiency. Unlike wooden pallets, which can absorb water and become heavy, or plastic pallets, which may deform under heat, GMT pallets maintain consistent performance across diverse conditions. This versatility makes them ideal for use in fully automatic, semi-automatic, and manual block machines, ensuring that block-making operations run smoothly and efficiently, regardless of the scale or complexity of the project.

Why GMT Brick Pallets Are the Future of Block Machine Operations?

As the block-making industry evolves, the demand for innovative, sustainable, and high-performing materials continues to grow. GMT brick pallets are at the forefront of this transformation, offering a forward-thinking solution that addresses the limitations of traditional pallets while meeting the needs of modern operations.

Adaptability to Modern Block Machines

GMT brick pallets are designed to complement the advanced capabilities of today’s block machines, including those manufactured by industry leaders like Raytone Machinery. Their uniform structure and resistance to deformation ensure compatibility with fully automatic block machines, semi-automatic brick machines, and manual block machines. This adaptability is particularly valuable for operations that require precision and consistency, as GMT pallets provide a stable foundation for producing high-quality concrete blocks. Unlike wooden pallets, which may warp and disrupt machine alignment, or plastic pallets, which can crack under pressure, GMT pallets enhance the efficiency and output of block machine pallets.

Meeting Global Sustainability Standards

Sustainability is no longer a buzzword but a critical priority for industries worldwide, including block-making. GMT brick pallets align seamlessly with this shift, offering an eco-conscious alternative that reduces waste and promotes resource efficiency. By utilizing recycled materials and minimizing the need for frequent replacements, GMT pallets help block-making operations lower their environmental impact. This is a significant advantage over plastic pallets, which contribute to non-biodegradable waste, and wooden pallets, which drive deforestation. For companies aiming to meet global sustainability standards and enhance their reputation, GMT brick pallets are a strategic and responsible choice.

Long-Term Value for Block-Making Businesses

Investing in GMT brick pallets is not just a practical decision but a strategic one, offering long-term value for block-making businesses. Their extended lifespan reduces the need for frequent replacements, lowering operational costs and minimizing downtime. Additionally, their lightweight and durable design improves workplace safety and efficiency, as workers can handle them with ease. For businesses using Raytone Machinery’s high-quality block machines, GMT pallets enhance overall performance, ensuring that every block produced meets stringent quality standards. By choosing GMT, companies position themselves as leaders in innovation, sustainability, and cost-efficiency, gaining a competitive edge in the global market.

Conclusion

GMT brick pallets offer a compelling alternative to traditional wooden and plastic pallets, combining durability, cost-effectiveness, and sustainability. With a lifespan of up to 10 years, resistance to water and temperature extremes, and an eco-friendly design, they outperform conventional options in every key area. For block-making operations seeking a reliable, long-term solution, GMT pallets are the clear choice, enhancing efficiency while reducing environmental impact.

Contact Us

At Raytone Machinery, we specialize in delivering high-quality block machines designed for performance and reliability. Pair our innovative machines with GMT brick pallets for optimal results. Contact us today at hazel@raytonechina.com to learn more about our cost-effective solutions and elevate your block-making operations.

References

- Smith, J. (2022). Composite Materials in Industrial Applications: A Focus on GMT Pallets. Industrial Engineering Journal, 45(3), 112-120.

- Patel, R. (2021). Sustainability in Construction: The Role of Eco-Friendly Pallets. Green Building Review, 18(2), 78-85.

- Nguyen, T. (2023). Durability of Pallet Materials in Block-Making Environments. Construction Technology Insights, 29(1), 56-63.

- Brown, L. (2020). Cost Analysis of Pallet Options in Industrial Settings. Manufacturing Economics, 12(4), 89-97.

- Garcia, M. (2022). Innovations in Block Machine Accessories: The Rise of GMT. Engineering Advances, 33(5), 101-108.

- Lee, K. (2021). Environmental Impact of Pallet Materials: A Comparative Study. Sustainable Industry Reports, 7(3), 44-52.