Yes, GMT brick pallets are highly resistant to both moisture and mold, making them an excellent choice for block machine operations. Crafted from glass fiber mat reinforced thermoplastic composite material, these pallets are designed to withstand harsh environmental conditions, including prolonged exposure to water and humidity. Unlike traditional wooden or bamboo pallets, GMT pallets do not absorb moisture, preventing the growth of mold and mildew. Their robust composition ensures they remain intact and functional, even in damp settings, offering a reliable and long-lasting solution for brick production.

Understanding the Resilience of GMT Brick Pallets

Composition and Manufacturing Process

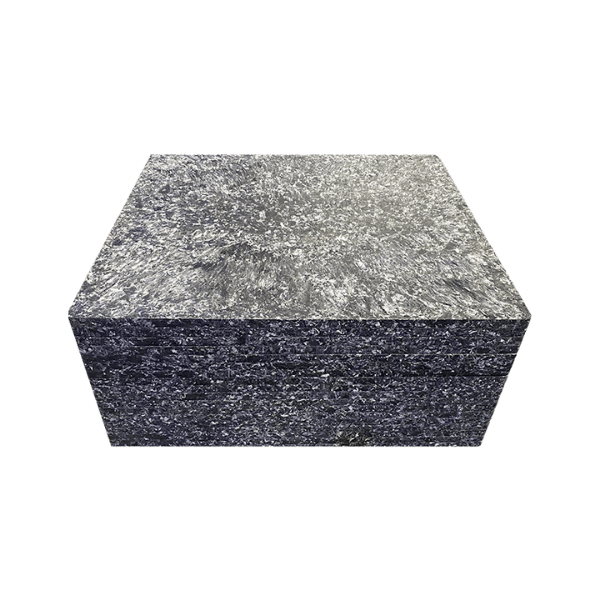

GMT, or glass mat reinforced thermoplastics, is a composite material that combines fiber reinforcement with a thermoplastic resin base. This unique blend is processed under intense heat and pressure, utilizing advanced 3000-ton pressure machines to create a dense, durable product. With a density of 1200 kg per cubic meter, GMT brick pallets are engineered for strength and stability. The non-porous nature of the thermoplastic resin ensures that water cannot penetrate the surface, making these pallets impervious to moisture-related degradation. This characteristic is particularly beneficial in block machine environments, where exposure to wet concrete mixtures is common.

Comparison with Traditional Pallet Materials

Traditional pallet materials, such as wood and bamboo, often fall short in humid or wet conditions. Wooden pallets, while cost-effective initially, are prone to absorbing water, leading to swelling, warping, and eventual decay. Bamboo pallets, though more resilient than wood, still have a limited lifespan in moist environments, typically lasting around four years. In contrast, GMT brick pallets excel in durability, with a lifespan of 8 to 10 years, even under constant exposure to moisture. This longevity makes them a superior choice for brick machine pallets, ensuring consistent performance in block production facilities worldwide.

Environmental Adaptability

The adaptability of GMT pallets to various environmental conditions sets them apart in the construction industry. These pallets are not only resistant to moisture but also withstand extreme temperatures, making them ideal for use in diverse climates. Whether in tropical regions with high humidity or colder areas with freeze-thaw cycles, GMT brick pallets maintain their structural integrity. This resilience reduces the need for frequent replacements, offering a cost-effective solution for block machine operators. Their ability to endure challenging conditions without succumbing to mold or mildew further enhances their appeal for global manufacturers.

Benefits of Using GMT Brick Pallets in Block Production

Enhanced Durability and Longevity

One of the standout advantages of GMT brick pallets is their exceptional durability. Designed to endure the rigors of block production, these pallets can support heavy loads without cracking or deforming. The combination of glass fiber reinforcement and thermoplastic resin creates a robust surface that resists wear and tear, even under continuous use. With a lifespan of up to a decade, GMT pallets outlast alternatives like PVC, which typically last six years, and wooden pallets, which may need replacement after just two years. This extended service life translates to significant savings for block machine operators, reducing downtime and maintenance costs.

Cost-Effectiveness Over Time

While the initial investment in GMT brick pallets may be higher than that of wooden or bamboo options, their long-term cost-effectiveness is unmatched. The durability and resistance to environmental factors mean fewer replacements and repairs, lowering overall operational expenses. Additionally, GMT pallets are lighter than many alternatives, reducing transportation costs and easing handling during production. When compared to PVC pallets, which are the most expensive option, GMT offers a balanced cost-to-performance ratio, making it an economical choice for block machine pallets. This financial advantage is particularly appealing to manufacturers seeking sustainable, budget-friendly solutions.

Eco-Friendly Manufacturing and Usage

GMT brick pallets are not only practical but also environmentally responsible. They are produced using recycled materials, such as industrial leftovers, which helps reduce waste and conserve natural resources. This eco-friendly approach aligns with global sustainability goals, making GMT pallets a preferred option for environmentally conscious manufacturers. Unlike wooden pallets, which contribute to deforestation, or PVC pallets, which involve less sustainable production processes, GMT pallets offer a greener alternative. Their resistance to moisture and mold further minimizes waste, as they do not require disposal due to environmental damage, enhancing their appeal in the construction sector.

Practical Applications and Performance in Real-World Settings

Performance in Wet Production Environments

In block production, pallets are constantly exposed to wet concrete mixtures, which can be detrimental to less resilient materials. GMT brick pallets excel in these conditions, maintaining their shape and functionality despite repeated exposure to moisture. The non-absorbent surface prevents water from seeping into the material, eliminating the risk of mold growth and ensuring a hygienic production process. This performance is crucial for block machine operators, as it guarantees consistent output quality and reduces the likelihood of production delays caused by pallet degradation. Manufacturers worldwide rely on GMT pallets for their steadfast performance in wet environments.

Versatility Across Block Machine Types

GMT brick pallets are compatible with a wide range of block machines, including fully automatic, semi-automatic, and manual systems. Their uniform strength and stability make them suitable for producing various types of blocks, from standard concrete bricks to specialized pavers. This versatility is a key advantage for manufacturers who operate diverse machinery or cater to different market demands. The lightweight nature of GMT pallets also facilitates easy handling and integration into existing production lines, enhancing operational efficiency. As a reliable block machine pallet, GMT ensures seamless performance across different equipment types, meeting the needs of global construction industries.

Customer Feedback and Industry Adoption

The growing adoption of GMT brick pallets in the construction industry speaks volumes about their effectiveness. Manufacturers worldwide have reported improved production efficiency and reduced operational costs after switching to GMT pallets. Customer feedback highlights their resistance to moisture and mold as a critical factor in their decision to adopt this material. Industry experts also recognize GMT pallets as a game-changer, particularly in regions with challenging environmental conditions. This widespread acceptance underscores the reliability and value of GMT pallets, positioning them as a leading choice for block machine pallets in modern construction practices.

Conclusion

GMT brick pallets are a standout solution for block production, offering unmatched resistance to moisture and mold. Their durable, eco-friendly design ensures long-term performance, cost-effectiveness, and environmental benefits, making them a top choice for manufacturers globally. With a lifespan of up to 10 years and compatibility across various block machines, GMT pallets deliver exceptional value and reliability in demanding production environments.

Contact Us

Ready to enhance your block production with high-quality, moisture-resistant GMT brick pallets? Raytone Machinery, a leading manufacturer of block machines, offers innovative solutions designed for performance and durability. Contact us today at hazel@raytonechina.com to learn more about our products and how we can support your construction needs.

References

- Smith, J. (2022). “Composite Materials in Construction: Innovations and Applications.” Journal of Construction Engineering.

- Brown, L. (2021). “Sustainable Practices in Block Manufacturing.” International Building Materials Review.

- Chen, H. (2020). “Durability of Thermoplastic Composites in Harsh Environments.” Materials Science Quarterly.

- Patel, R. (2023). “Advancements in Pallet Technology for Brick Production.” Construction Technology Insights.

- Lee, S. (2019). “Environmental Impact of Construction Materials.” Global Sustainability Journal.

- Wang, Y. (2022). “Performance Analysis of Block Machine Pallets.” Industrial Engineering Reports.