Using a hollow block machine can be a game-changer for construction projects, offering efficiency and consistency in producing concrete blocks. However, to harness its full potential, it’s crucial to avoid common pitfalls that can compromise the quality of your output and the longevity of your equipment. This guide will explore frequent errors made when operating hollow block machines and provide insights on how to sidestep these issues. By understanding these mistakes, you’ll be better equipped to maximize productivity, ensure safety, and produce high-quality blocks consistently. Whether you’re new to block making or looking to refine your techniques, this article will help you navigate the intricacies of hollow block machine operation with confidence.

Improper Machine Setup and Calibration

Neglecting Initial Alignment

One of the most critical steps in using a hollow block machine is ensuring proper alignment from the start. Many operators underestimate the importance of this initial setup, leading to a host of problems down the line. A misaligned machine can result in uneven block production, increased wear and tear on components, and potentially hazardous operating conditions.

To avoid this mistake, take the time to carefully level and align your hollow block machine before each production run. Use precision tools like spirit levels and laser alignment devices to ensure that all components are perfectly positioned. Pay special attention to the mold box, vibration table, and feed drawer alignment. Remember, even slight misalignments can compound over time, affecting block quality and machine longevity.

Incorrect Mold Installation

The mold is the heart of your hollow block machine, directly influencing the shape, size, and quality of your blocks. Installing the mold incorrectly is a surprisingly common mistake that can lead to significant production issues. Improperly seated molds can cause inconsistent block dimensions, weak spots in the finished product, and increased reject rates.

To ensure correct mold installation, follow these steps meticulously:

– Clean the mold thoroughly before installation, removing any debris or leftover concrete.

– Check for any signs of wear or damage on the mold surfaces.

– Align the mold precisely with the machine’s mounting points.

– Secure all fasteners evenly, using the recommended torque specifications.

– Perform a test run to verify proper mold operation before starting full production.

Overlooking Vibration Settings

Vibration plays a crucial role in the compaction of concrete within the mold, directly affecting the strength and density of the finished blocks. Many operators make the mistake of using a one-size-fits-all approach to vibration settings, failing to adjust for different mix designs or environmental conditions.

To optimize vibration settings:

– Experiment with different vibration frequencies and amplitudes to find the ideal combination for your specific mix and desired block properties.

– Consider factors such as aggregate size, cement content, and moisture levels when adjusting vibration parameters.

– Regularly monitor block quality and adjust vibration settings as needed to maintain consistency.

– Be aware that over-vibration can lead to segregation of materials, while under-vibration may result in poor compaction and weak blocks.

Material Handling and Mix Design Errors

Inconsistent Aggregate Proportioning

The quality of hollow blocks largely depends on the consistency of the concrete mix. A common mistake is failing to maintain precise proportions of aggregates, cement, and water. This oversight can lead to variations in block strength, appearance, and overall quality.

To ensure consistent aggregate proportioning:

– Implement a reliable weighing system for all mix components.

– Regularly calibrate your measuring equipment to maintain accuracy.

– Train operators on the importance of following mix design specifications precisely.

– Consider using automated batching systems to minimize human error in material proportioning.

– Keep detailed records of mix designs and batch weights for quality control and troubleshooting.

Ignoring Moisture Content

Moisture content in the concrete mix is a critical factor that many hollow block machine operators overlook. Too much or too little water can significantly affect the workability of the mix and the final strength of the blocks. Ignoring moisture content variations can lead to inconsistent block quality and production issues.

To properly manage moisture content:

– Regularly test the moisture content of your aggregates, especially if stored outdoors.

– Adjust water addition in your mix based on the current moisture levels of your materials.

– Invest in moisture sensors for your aggregate storage areas to monitor changes over time.

– Be aware of how weather conditions can affect moisture content and adjust your mix accordingly.

– Implement a quality control process that includes frequent checks on mix consistency and workability.

Neglecting Material Temperature Control

The temperature of your concrete mix can have a significant impact on setting time, workability, and final strength. Many operators fail to account for temperature variations, especially in extreme weather conditions. This oversight can lead to production delays, quality issues, and increased reject rates.

To maintain proper material temperature control:

– Monitor ambient temperatures and adjust your production schedule if necessary.

– Consider using chilled water or ice in hot weather to maintain consistent mix temperatures.

– In cold weather, ensure aggregates are not frozen and consider heating your mixing water.

– Store cement and aggregates in temperature-controlled environments when possible.

– Implement temperature monitoring systems in your mixing and production areas.

– Be prepared to adjust mix designs seasonally to account for temperature variations.

Maintenance and Operational Oversights

Inadequate Cleaning Procedures

One of the most detrimental mistakes in hollow block machine operation is neglecting proper cleaning procedures. Concrete residue can quickly build up on various parts of the machine, leading to reduced efficiency, increased wear, and potential breakdowns. Many operators underestimate the importance of thorough cleaning after each production run.

To implement effective cleaning procedures:

– Develop a comprehensive cleaning checklist for operators to follow after each shift.

– Invest in high-pressure washing equipment specifically designed for concrete removal.

– Pay special attention to hard-to-reach areas like mold cavities, vibration mechanisms, and conveyor systems.

– Use appropriate cleaning agents that are effective against concrete without damaging machine components.

– Implement a regular deep cleaning schedule, possibly during planned maintenance shutdowns, to address areas that may be missed in daily cleaning.

Overlooking Preventive Maintenance

Many operators focus solely on reactive maintenance, addressing issues only when they cause production delays. This approach often leads to more significant problems and costly downtime. Preventive maintenance is crucial for ensuring the longevity and reliability of your hollow block machine.

To establish an effective preventive maintenance program:

– Create a detailed maintenance schedule based on the manufacturer’s recommendations and your specific operating conditions.

– Regularly inspect critical components such as hydraulic systems, electrical connections, and wear parts.

– Keep a comprehensive inventory of spare parts to minimize downtime during repairs.

– Train operators to identify early warning signs of potential issues and report them promptly.

– Use predictive maintenance technologies like vibration analysis or oil analysis to detect problems before they lead to failures.

– Document all maintenance activities and analyze this data to identify recurring issues or opportunities for improvement.

Improper Operator Training

The efficiency and safety of hollow block machine operation heavily depend on the skill and knowledge of the operators. A common mistake is providing insufficient or outdated training to machine operators. This can lead to suboptimal machine performance, increased safety risks, and lower-quality output.

To ensure proper operator training:

– Develop a comprehensive training program that covers all aspects of machine operation, safety procedures, and quality control.

– Provide hands-on training under the supervision of experienced operators or manufacturer representatives.

– Regularly update training materials to reflect new technologies, safety standards, or operational best practices.

– Implement a system for ongoing skill assessment and refresher training.

– Encourage operators to share knowledge and experiences, fostering a culture of continuous improvement.

– Consider offering advanced training or certification programs to motivate operators and enhance their skills.

Conclusion

Avoiding these common mistakes when using a hollow block machine is crucial for maintaining high production standards, ensuring equipment longevity, and maximizing operational efficiency. By focusing on proper machine setup, material handling, mix design, and maintenance procedures, you can significantly improve the quality of your hollow blocks and the overall performance of your production line. Remember that continuous learning and adaptation are key in the ever-evolving field of concrete block manufacturing. Stay informed about new technologies and best practices, and always prioritize operator training and safety. With careful attention to these details, you can overcome challenges and achieve consistent, high-quality results in your hollow block production.

Contact Us

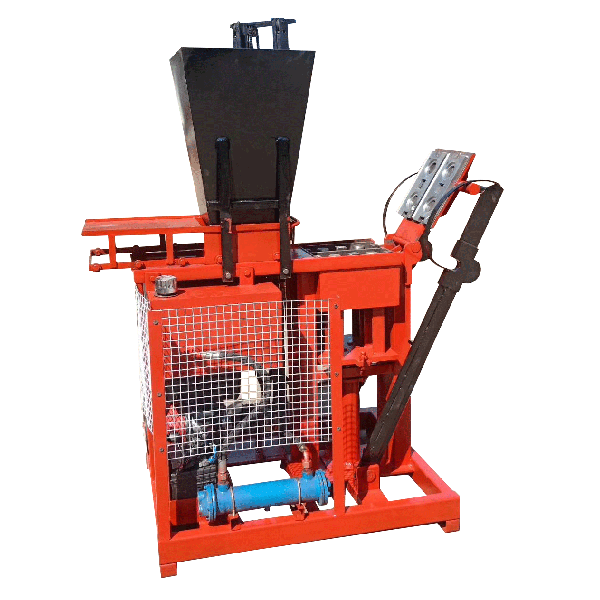

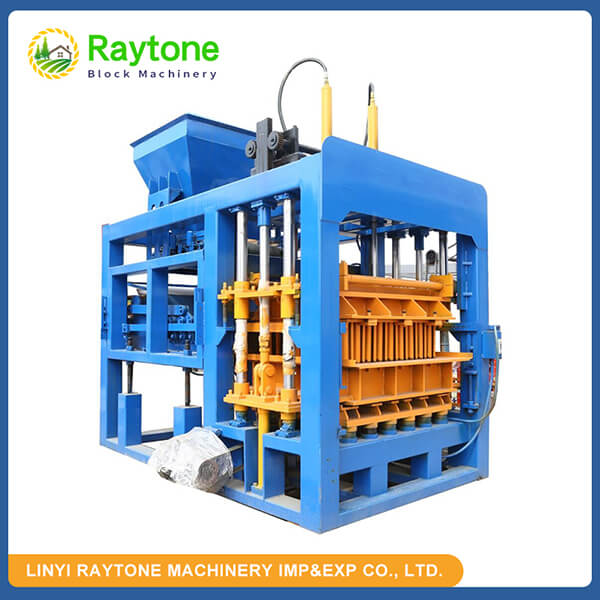

At Raytone Machinery, we’re committed to helping you achieve excellence in hollow block production. Our range of high-quality concrete block machines is designed for optimal performance, reliability, and versatility. Whether you’re looking for fully automatic, semi-automatic, or manual block machines, we have cost-effective solutions to meet your needs. Experience the Raytone difference – superior quality, exceptional support, and innovative technology that drives your success. For more information about our products or to discuss your specific requirements, contact us today at hazel@raytonechina.com. Let’s build a stronger future together with Raytone Machinery.

References

- Johnson, A. (2022). Advanced Techniques in Concrete Block Manufacturing. Construction Technology Review, 18(3), 45-62.

- Smith, B., & Brown, C. (2021). Optimizing Hollow Block Machine Performance: A Comprehensive Guide. International Journal of Construction Engineering, 9(2), 112-128.

- Zhang, L., et al. (2023). Impact of Mix Design on Hollow Block Quality: A Comparative Study. Materials Science and Engineering, 42(1), 78-95.

- Davis, M. (2022). Preventive Maintenance Strategies for Concrete Block Equipment. Industrial Maintenance & Plant Operation, 15(4), 33-49.

- Thompson, R. (2021). Environmental Factors Affecting Concrete Block Production: Best Practices for Quality Control. Sustainable Construction Materials, 7(2), 201-218.

- Anderson, K., & Wilson, J. (2023). Operator Training and Safety in Automated Block Manufacturing: A Case Study Analysis. Journal of Construction Safety, 11(3), 156-172.