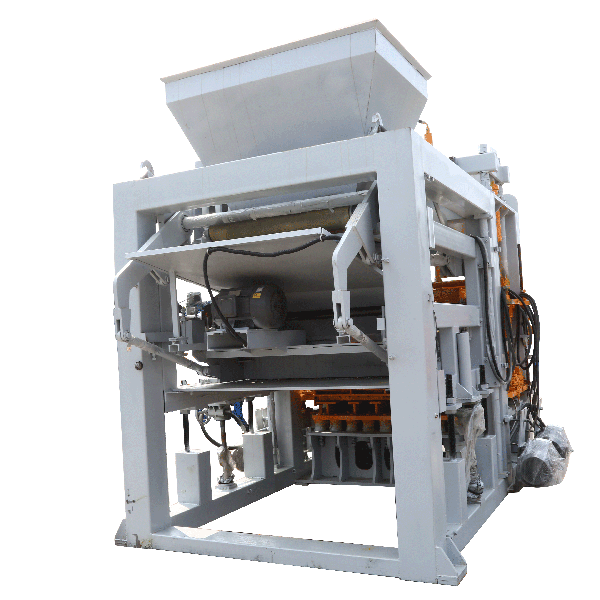

Maintaining your automatic hydraulic concrete block machine is crucial for ensuring its longevity, efficiency, and consistent production of high-quality blocks. Regular upkeep not only prevents costly breakdowns but also optimizes performance, reducing downtime and increasing productivity. This comprehensive guide will walk you through essential maintenance practices for your block making equipment, including the popular QT4-18 automatic brick making machine. By following these tips, you’ll keep your machinery running smoothly, extend its lifespan, and maximize your return on investment in the competitive construction industry.

Daily Inspection and Cleaning Routines

Pre-operation Checks

Before starting your automatic hydraulic concrete block machine each day, it’s essential to perform a thorough visual inspection. Check for any signs of wear, such as frayed hoses or loose bolts, and look for damaged components that may impact machine performance. Inspect hydraulic hoses for leaks or cracks, ensuring there are no potential safety hazards. Confirm that all safety guards are securely in place, and verify that the control panel is functioning properly. Lastly, ensure emergency stop buttons are easily accessible and in good working condition for operator safety.

Cleaning Procedures

Cleanliness is essential for the optimal performance and longevity of your block making equipment. After each production cycle, ensure you thoroughly remove any excess concrete or debris from the mold box, tamper head, and feeder box to prevent block defects. Use compressed air to clean hard-to-reach areas, but be cautious not to force debris into delicate components. For machines like the QT4-18 automatic brick making machine, pay extra attention to the pallet feeder mechanism, ensuring it remains free from blockages that could disrupt the flow of production or cause malfunctions.

Lubrication Points

Identify and lubricate all grease points on your automatic hydraulic concrete block machine daily to ensure smooth operation. This includes bearings, sliding surfaces, and pivot points. Always use the manufacturer-recommended lubricant and avoid over-greasing, as excess grease can attract dust and debris, leading to wear. For hydraulic components, regularly check the oil levels and top up if necessary, using the correct hydraulic fluid for your specific machine model. Keeping these systems well-maintained reduces friction, extends the machine’s lifespan, and ensures consistent, high-quality production.

Weekly and Monthly Maintenance Tasks

Hydraulic System Maintenance

The hydraulic system is the heart of your automatic hydraulic concrete block machine. Weekly, inspect hydraulic cylinders for smooth operation and any signs of leakage. Check and clean hydraulic filters, replacing them as needed. Monthly, analyze hydraulic fluid samples to detect contamination or degradation. If your QT4-18 automatic brick making machine shows signs of reduced hydraulic pressure, consult the manual for troubleshooting steps or contact a specialist.

Electrical System Checks

Regularly inspect electrical connections to ensure they are tight and free from signs of corrosion, which could lead to electrical failures. Clean control panels to keep them free from dust, moisture, or debris, as these can interfere with the system’s performance. Test safety interlocks and emergency stop functions to ensure they’re operating correctly for operator safety. For PLC-controlled machines, don’t forget to back up program settings and review error logs, as these may highlight potential issues that could cause downtime or affect production efficiency.

Vibration System Upkeep

The vibration system of an automatic hydraulic concrete block machine plays a key role in ensuring efficient block compaction, directly affecting the quality of the final product. Regularly check the vibrator mounts to ensure they are securely fastened and free from signs of wear. Vibrator bearings should be inspected periodically, and any unusual noise or heat buildup should prompt an immediate replacement to avoid further damage. Additionally, for machines with adjustable vibration settings, it’s important to ensure they are correctly calibrated according to the specific block types and mix designs, as this ensures optimal performance and consistency.

Long-term Maintenance Strategies

Scheduled Overhauls

Plan for comprehensive overhauls of your automatic hydraulic concrete block machine at intervals recommended by the manufacturer. This typically involves disassembling major components, inspecting for wear, and replacing parts as necessary. For the QT4-18 automatic brick making machine, pay particular attention to the mold box, tamper head, and hydraulic cylinders, as these components undergo the most stress during operation.

Operator Training and Documentation

Invest in ongoing training for machine operators and maintenance staff working with the automatic hydraulic concrete block machine. Well-trained personnel can spot potential issues early and perform routine maintenance tasks efficiently. Maintain detailed maintenance logs for each machine, recording all inspections, repairs, and part replacements. This documentation is invaluable for tracking machine history and planning preventive maintenance.

Upgrading and Modernization

Stay informed about technological advancements in block making equipment. Consider upgrading control systems or retrofitting older machines with newer, more efficient components. This can breathe new life into older equipment, improving productivity and reducing energy consumption. For example, upgrading the control system on an older automatic hydraulic concrete block machine can provide more precise control over mix design and compaction, resulting in higher quality blocks.

Conclusion

Proper maintenance of your automatic hydraulic concrete block machine is essential for ensuring consistent production, high-quality output, and long-term reliability. By implementing these maintenance tips, from daily cleaning routines to long-term overhaul strategies, you’ll maximize the efficiency and lifespan of your equipment. Remember that preventive maintenance is always more cost-effective than reactive repairs. Invest the time and resources in caring for your block making machinery, and it will reward you with years of dependable service and quality block production.

Contact Us

At Raytone Machinery, we’re committed to helping you get the most out of your block making equipment. Our range of automatic hydraulic concrete block machines, including the popular QT4-18 automatic brick making machine, are designed for durability and ease of maintenance. For more information on our products or expert advice on maintaining your block making equipment, don’t hesitate to reach out to us at hazel@raytonechina.com. Let us help you build a stronger future, one block at a time.

References

- Johnson, R. (2022). Hydraulic Systems Maintenance for Construction Equipment. Industrial Machinery Digest.

- Smith, A. (2023). Optimizing Concrete Block Production: Machine Maintenance and Best Practices. Construction Technology Review.

- Zhang, L. et al. (2021). Predictive Maintenance Strategies for Automated Concrete Block Manufacturing. Journal of Construction Engineering.

- Brown, T. (2023). Energy Efficiency in Block Making: The Role of Well-Maintained Equipment. Sustainable Construction Magazine.

- Davies, M. (2022). Safety First: Maintenance Protocols for Concrete Block Machines. Occupational Safety in Construction.

- Patel, S. (2023). Innovations in Concrete Block Machine Design: Maintenance Considerations. Advanced Manufacturing Technology.