In the competitive landscape of modern block manufacturing, efficiency, precision, and durability define success. As block making technology continues to evolve, the demand for high-performance supporting equipment, particularly GMT brick pallets, has surged. These innovative pallets have become an essential component in block machine production lines, offering outstanding load-bearing capacity, dimensional stability, and customization flexibility.

The Role of GMT Brick Pallets in Block Machine Production

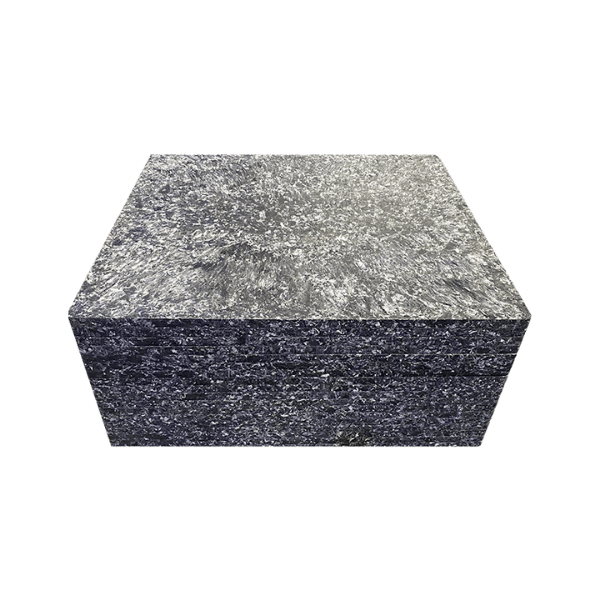

Every block making machine—whether it’s a fully automatic brick machine like QT4-15, a semi-automatic QT4-24, or a mobile unit such as QTM6-25—requires reliable pallets for molding, curing, and transporting concrete blocks. GMT (Glass Mat Thermoplastic) pallets have emerged as the top choice for manufacturers due to their superior mechanical properties and long lifespan. Unlike traditional wooden or PVC pallets, GMT pallets deliver consistent performance under high pressure and intensive vibration, ensuring stable block shape and smooth production cycles.

Customization: Meeting Every Manufacturing Need

The strength of custom GMT brick pallets lies in their adaptability. Each production line has its unique operational parameters, and pallet specifications must align with machine models and block sizes. Manufacturers can fully customize:

-

Dimensions and Thickness: Common sizes like 850×680mm, 1000×550mm, and 1100×950mm can be modified to meet specific block machine mold requirements. Thickness typically ranges from 8mm to 12mm, depending on load demands.

-

Surface Texture: Anti-slip surfaces or reinforced grid patterns can be applied for better grip and block stability during vibration.

-

Load Capacity: Depending on production needs, GMT pallets can support loads from 1000kg to 2500kg, maintaining strength without excess weight.

-

Reinforcement Design: Internal fiber layout and density can be adjusted for heavy-duty brick machine operations.

Such customization ensures compatibility with diverse block production systems, from hollow block machines to paving brick and curb stone production lines.

Technical Advantages of GMT Material

GMT composite material combines glass fiber with thermoplastic resin, forming a lightweight yet extremely durable matrix. With a density of around 1200 kg/m³, GMT pallets maintain optimal stiffness and toughness, even under continuous vibration and hydraulic pressure. Key advantages include:

-

Waterproof and corrosion-resistant – ideal for wet concrete environments.

-

Temperature stability – performance remains steady in both tropical and cold regions.

-

Long service life – up to 8–10 years, outlasting wooden and bamboo pallets.

-

Eco-friendly production – made from recycled materials and recyclable after use.

These properties make GMT pallets the preferred choice for manufacturers aiming to upgrade their automatic block making machines or expand production capacity.

Economic and Operational Benefits

While the upfront investment in GMT pallets is moderate, their long-term value is unmatched. Reduced breakage, minimal maintenance, and consistent production quality translate into significant cost savings. Compared with PVC pallets, GMT options are typically 20–30% more affordable while offering better performance and longevity.

Moreover, the dimensional precision of GMT pallets enhances machine compatibility, reducing downtime and improving overall output rates. Factories using Raytone Machinery’s GMT brick pallets report improved block uniformity, lower defect rates, and smoother automation in stacking and curing systems.

Sustainable Manufacturing and Global Compliance

In today’s environmentally conscious market, manufacturers are under increasing pressure to adopt sustainable materials. GMT brick pallets are not only eco-friendly but also compliant with international environmental regulations. Their recyclable composition and long lifespan help minimize industrial waste and carbon footprint, supporting global sustainability goals in the construction industry.

Why Choose Raytone Machinery

As a leading manufacturer in the block making machine industry, Raytone Machinery offers complete customization for GMT brick pallets tailored to your specific production line. With years of experience serving clients in Africa, the Middle East, and Latin America, Raytone provides:

-

Tailor-made pallet design for all major block machine models (QT4-15, QT6-15, QT10-15, etc.)

-

Factory-direct pricing and quality assurance

-

Global technical support and on-site installation

-

24/7 after-sales service and spare parts supply

Conclusion

Customized GMT brick pallets represent a powerful upgrade for any modern block production line. Their blend of durability, customization flexibility, and sustainability ensures maximum productivity and long-term savings. Whether you’re running a large-scale concrete block factory or a local construction materials business, adopting Raytone’s GMT pallet solutions will elevate your manufacturing performance and profitability.

Contact Raytone Machinery today at 📧 hazel@raytonechina.com to explore customized GMT brick pallet options that perfectly match your block making machine and production requirements. Experience the synergy of innovation, quality, and efficiency—built for the future of brick manufacturing.