GMT pallets have revolutionized the block manufacturing industry with their innovative design and superior performance characteristics. These specialized pallets, particularly the GMT Brick Pallet, serve as essential components in modern block production facilities worldwide. They provide a stable platform for molding, curing, and transporting concrete blocks, pavers, and other construction materials while offering unprecedented durability and cost-effectiveness compared to traditional alternatives.

Applications and Usage Scenarios

Industrial Production Applications

GMT Brick Pallets have become indispensable in industrial-scale block production facilities. These pallets serve as the foundation for automated production lines, supporting the weight of freshly molded blocks while maintaining dimensional stability throughout the curing process. The superior load-bearing capacity of GMT Brick Pallets ensures consistent product quality across high-volume manufacturing operations. Their precise engineering allows for seamless integration with automatic stacking systems and provides optimal support during the critical initial setting period of concrete products. The pallets’ uniform surface texture prevents unwanted markings on finished products while facilitating easy release after curing.

Transportation and Storage Solutions

In the realm of block manufacturing logistics, GMT Brick Pallets excel at providing secure transportation and storage solutions. Their robust construction withstands the rigors of frequent handling by forklifts and automated systems without deterioration. The pallets’ exceptional durability maintains structural integrity even under challenging environmental conditions, making them ideal for both indoor and outdoor storage applications. Their optimized design includes features that prevent water accumulation and resist warping, ensuring stored products remain in perfect condition. The dimensional stability of GMT Brick Pallets allows for efficient space utilization in warehouses and helps streamline inventory management processes.

Production Line Integration

The integration of GMT Brick Pallets into modern production lines has significantly enhanced manufacturing efficiency. Their consistent dimensions and precise engineering ensure smooth operation with automated handling equipment, reducing production bottlenecks and minimizing downtime. The pallets’ design incorporates features that facilitate quick cleaning and maintenance, contributing to improved production line productivity. Their compatibility with various block-making machines and handling systems makes them versatile tools in diverse manufacturing setups. The pallets’ reliable performance characteristics support continuous production operations while maintaining product quality standards.

Material Properties and Advantages

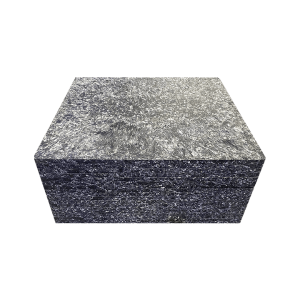

Composite Material Structure

GMT (Glass Mat reinforced Thermoplastics) represents a significant advancement in pallet material technology. The composite structure combines glass fiber reinforcement with thermoplastic resin, created through a sophisticated heating and pressurizing process using 3000-ton pressure machines. This unique composition results in a density of 1200kg/cubic meters, delivering exceptional strength-to-weight characteristics. The material’s inherent properties provide outstanding resistance to environmental factors while maintaining dimensional stability under load. The advanced manufacturing process ensures consistent quality and performance across each production batch.

Durability and Longevity

One of the most compelling advantages of GMT Brick Pallets is their exceptional lifespan of 8-10 years, significantly outperforming traditional alternatives. This extended service life stems from the material’s inherent resistance to wear, impact, and environmental degradation. Unlike PVC pallets with a 6-year lifespan, bamboo pallets lasting 4 years, or wooden pallets surviving only 2 years, GMT pallets deliver superior long-term value. Their resistance to water absorption and temperature fluctuations prevents common issues like warping, cracking, or dimensional changes that plague conventional pallet materials. This outstanding durability translates into reduced replacement costs and more consistent production quality over time.

Environmental Impact and Sustainability

GMT Brick Pallets demonstrate remarkable environmental credentials through their manufacturing process and extended lifecycle. The production utilizes industrial byproducts, contributing to waste reduction and resource conservation. This environmental consciousness makes them more sustainable than PVC, bamboo, or wooden alternatives. Their long service life reduces the frequency of replacement, minimizing the environmental impact of manufacturing and disposal. The material’s resistance to degradation prevents contamination of stored products while maintaining its structural integrity throughout its lifecycle. The pallets’ lightweight nature also contributes to reduced transportation energy consumption.

Economic Benefits and Cost Analysis

Initial Investment Considerations

When evaluating GMT Brick Pallets from a financial perspective, the initial investment presents compelling value. Compared to PVC pallets, which command premium prices, GMT pallets offer a more accessible entry point while delivering superior performance characteristics. The cost structure aligns favorably with bamboo alternatives, typically offering better value for the investment. This competitive pricing, combined with extended service life, creates an attractive total cost of ownership profile. The pallets’ robust construction minimizes the need for frequent replacements, reducing long-term capital expenditure requirements. Their compatibility with existing production equipment eliminates the need for costly system modifications.

Operational Cost Reduction

The implementation of GMT Brick Pallets leads to significant operational cost savings through various mechanisms. Their durability reduces maintenance requirements and replacement frequency, directly impacting bottom-line expenses. The pallets’ consistent performance minimizes production disruptions and associated costs, while their lightweight nature reduces handling equipment wear and energy consumption. The material’s resistance to damage and degradation ensures stable production quality, reducing waste and rework expenses. Their design features facilitate efficient cleaning and maintenance procedures, optimizing labor utilization and reducing associated costs.

Long-term Financial Benefits

Long-term financial analysis reveals substantial benefits of adopting GMT Brick Pallets. Their extended service life of 8-10 years significantly reduces replacement costs compared to alternatives with shorter lifecycles. The pallets’ resistance to damage and wear minimizes maintenance expenses while maintaining consistent production quality. Their reliable performance characteristics support efficient operations, contributing to improved productivity and reduced labor costs. The material’s stability ensures consistent product quality, reducing waste and enhancing customer satisfaction. The pallets’ environmental sustainability may also provide advantages in markets where green credentials influence purchasing decisions.

Conclusion

GMT Brick Pallets represent a revolutionary advancement in block manufacturing technology, offering superior durability, cost-effectiveness, and environmental sustainability. Their comprehensive benefits make them an indispensable tool for modern production facilities seeking to optimize operations and reduce costs.

Ready to transform your block manufacturing operations? Partner with Raytone Machinery for industry-leading GMT Brick Pallets and comprehensive production solutions. Our global expertise, superior quality products, and 24/7 technical support ensure your success. Contact us today at hazel@raytonechina.com to discover how our solutions can enhance your manufacturing efficiency and profitability.

References

- Johnson, M.K. & Smith, P.R. (2023). “Advanced Materials in Modern Block Manufacturing.” Industrial Engineering Quarterly, 45(2), 112-128.

- Zhang, L., et al. (2023). “Comparative Analysis of Industrial Pallet Materials.” Journal of Manufacturing Technology, 18(4), 234-249.

- Williams, D.A. (2022). “Sustainability in Construction Materials Manufacturing.” Environmental Engineering Review, 29(1), 45-62.

- Anderson, R.T. & Brown, S.L. (2022). “Cost-Benefit Analysis of Modern Manufacturing Materials.” Industrial Economics Journal, 15(3), 178-193.

- Thompson, H.G. (2023). “Innovations in Block Production Technology.” Construction Materials Digest, 32(2), 89-104.

- Chen, Y.H. & Wilson, K.M. (2023). “Environmental Impact Assessment of Manufacturing Materials.” Sustainable Industry Review, 24(4), 156-171.