In today’s construction industry, sustainability and performance go hand in hand. Manufacturers are looking for ways to reduce environmental impact while improving production efficiency and product lifespan. One innovation that perfectly balances these needs is the GMT brick pallet — a new-generation block machine pallet made from glass fiber mat reinforced thermoplastic (GMT) material. Durable, recyclable, and cost-effective, GMT brick pallets are rapidly becoming the preferred choice for modern block-making plants worldwide.

What Are GMT Brick Pallets?

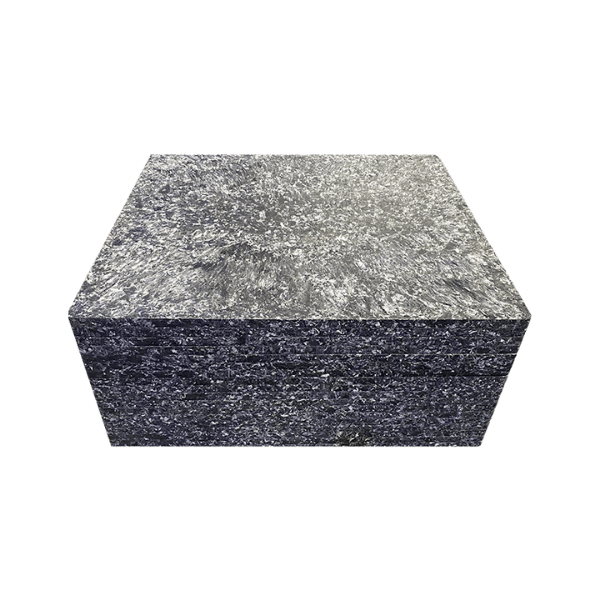

GMT (Glass Mat Thermoplastic) brick pallets are composite pallets specially designed for concrete block machines. They are manufactured using fiberglass reinforcement combined with thermoplastic resin under high temperature and high pressure (around 3000 tons). This advanced process ensures superior strength, rigidity, and dimensional stability.

Unlike traditional wooden, bamboo, or PVC pallets, GMT brick pallets are engineered for industrial applications that demand both toughness and environmental responsibility. With a density of around 1200 kg/m³, they offer a lightweight yet solid solution for smooth block molding and long-term durability.

Eco-Friendly Advantages of GMT Brick Pallets

Environmental protection has become a key priority for the global construction sector. GMT block pallets stand out as a truly eco-friendly alternative for several reasons:

-

Made from Recycled Materials

The base materials used in GMT pallets can include recycled thermoplastics and industrial waste fibers. This reuse of leftover resources reduces landfill waste and supports circular economy principles. -

Non-toxic and Safe

GMT materials are free from harmful chemicals or formaldehyde — unlike some wooden or PVC pallets. They do not release toxic substances during production or use, making them safer for workers and the environment. -

Longer Lifespan, Less Waste

With a service life of 8–10 years, GMT brick pallets outlast wooden pallets (2 years) and bamboo pallets (4 years). This durability dramatically lowers replacement frequency and reduces waste over time. -

Conservation of Natural Resources

By replacing wood and bamboo, GMT pallets help minimize deforestation and over-harvesting, protecting forests and ecosystems while providing a sustainable alternative. -

Fully Recyclable

At the end of their life cycle, GMT pallets can be reprocessed and reused, creating a closed-loop production system with minimal environmental impact.

Performance and Durability Beyond Comparison

While being eco-friendly, GMT brick pallets also deliver exceptional performance for modern block-making machines. Their mechanical strength and resistance to external stress ensure consistent, reliable operation in demanding production environments.

-

High Strength and Stability

GMT pallets maintain shape under pressure and vibration, ensuring the uniformity of bricks and blocks. Their bending strength and impact resistance outperform both bamboo and PVC alternatives. -

Waterproof and Moisture-Resistant

Unlike wooden pallets that absorb water and deform easily, GMT pallets are 100% waterproof. This makes them ideal for humid or coastal regions. -

Temperature and Chemical Resistance

GMT pallets can endure extreme temperatures and exposure to cement slurry or alkaline environments without warping, cracking, or corroding — a key factor for long-term block production stability. -

Smooth Surface for Better Block Quality

The non-stick surface of GMT pallets prevents cement adhesion, ensuring smoother, cleaner brick shapes and reducing maintenance needs for block machines.

Economic and Operational Benefits

Choosing GMT pallets for block machines is not just an environmental decision — it’s also a smart business investment.

-

Lower Lifecycle Cost: Although the initial cost may be slightly higher than wooden pallets, the 10-year service life means far less replacement and lower long-term expense.

-

Energy and Labor Savings: The lighter weight of GMT pallets simplifies manual handling and reduces power consumption during production and transport.

-

Reduced Downtime: Their high strength and consistency minimize machine wear and downtime caused by pallet deformation.

-

Improved Production Efficiency: GMT pallets work perfectly with automatic, semi-automatic, and manual block machines, making them a universal, cost-efficient choice for all manufacturers.

For companies aiming to enhance operational efficiency while maintaining eco-conscious standards, GMT pallets offer the best balance between durability, cost, and sustainability.

Comparing GMT Brick Pallets with Traditional Materials

| Pallet Type | Average Lifespan | Main Material | Environmental Impact | Durability | Cost Efficiency |

|---|---|---|---|---|---|

| Wooden Pallet | 2 years | Natural wood | Causes deforestation | Weak | Low |

| Bamboo Pallet | 4 years | Bamboo fiber | Renewable but short life | Medium | Medium |

| PVC Pallet | 6 years | Plastic resin | Non-biodegradable | Good | High cost |

| GMT Pallet | 8–10 years | Glass fiber + thermoplastic | Recyclable, eco-friendly | Excellent | High value |

It’s clear that GMT block machine pallets outperform traditional materials in almost every category — especially when considering long-term environmental and economic benefits.

GMT Pallets and the Global Push for Sustainable Construction

The shift toward sustainable construction is not just a trend — it’s the future of the building materials industry. Using GMT brick pallets directly supports global environmental goals by:

-

Reducing carbon footprint and raw material consumption

-

Minimizing industrial waste

-

Extending product life cycles

-

Promoting recycling and resource efficiency

For manufacturers, distributors, and construction companies, adopting GMT pallets means taking an active role in green manufacturing while maintaining competitive advantages in product performance and quality.

Why Choose Raytone Machinery’s GMT Brick Pallets

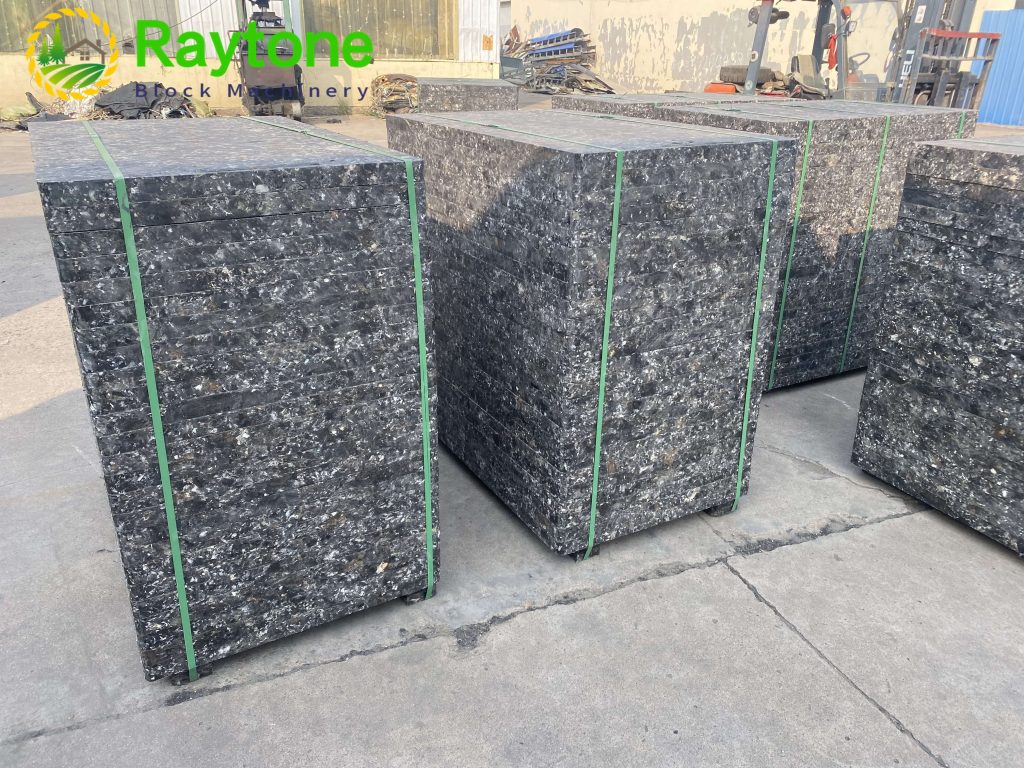

As a leading manufacturer and exporter of brick-making machines and accessories, Raytone Machinery provides premium-quality GMT brick pallets that meet international standards. Our pallets are:

-

Produced under strict quality control using advanced compression molding technology.

-

Compatible with QT4-18, QT4-24, QT6-15, QT10-15 and other block machine models.

-

Available in custom sizes (e.g., 850×680×35mm, 1200×900×40mm, etc.) to fit your exact production requirements.

-

Designed for high performance, long lifespan, and eco-friendly operation.

By partnering with Raytone, you gain not only reliable equipment but also a commitment to sustainable progress and customer satisfaction.

Conclusion: Building a Greener Future with GMT Brick Pallets

The transition to GMT block machine pallets marks a major step toward sustainability in the construction materials industry. Combining eco-friendliness, exceptional durability, and cost-efficiency, they provide a long-term solution for block manufacturers seeking to balance productivity with environmental responsibility.

By choosing Raytone GMT brick pallets, you’re not just upgrading your production system — you’re investing in a smarter, cleaner, and more sustainable future.

Contact Raytone Machinery

Make your block production greener today.

📧 Email: hazel@raytonechina.com

🌍 Website: www.raytonechina.com

📞 WhatsApp: +86 18953993388

Discover how Raytone’s GMT brick pallets can boost your efficiency, reduce waste, and elevate your brand’s environmental reputation.