Yes, GMT pallets are engineered to meet the diverse demands of the modern block and brick production industry. Designed for compatibility, durability, and operational efficiency, GMT pallets serve as a reliable solution for virtually all types of block machines, including manual, semi-automatic, and fully automatic systems. Whether you operate a QT series, HESS, MASA, ZENITH, or other major brand, GMT pallets are engineered to integrate seamlessly into your production line, optimizing performance and minimizing downtime.

Versatility and Compatibility of GMT Pallets

Customizable Dimensions for Different Machine Specifications

One of the primary advantages of GMT pallets is their customizable design. Manufacturers can tailor the pallet dimensions to match specific block machine requirements, ensuring precise alignment and smooth operation. This flexibility is crucial for facilities operating multiple brands or models, as GMT pallets can be adapted to both small-scale manual machines and high-capacity automated block production lines. By providing a perfect fit, these pallets help maintain uniform block quality and enhance overall production efficiency.

Material Properties Enhancing Strength and Longevity

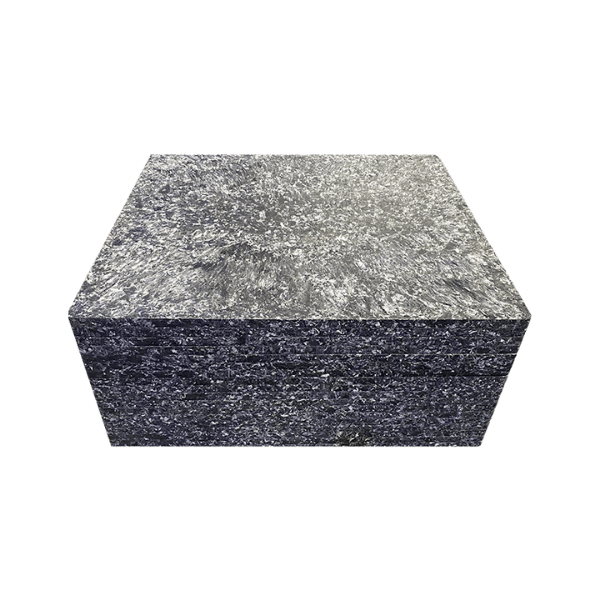

GMT pallets are constructed from high-quality, high-density polymer composites reinforced with glass fiber, offering excellent resistance to wear, deformation, and impact. This robust material composition ensures long-term durability even under heavy-duty use. The pallets maintain structural integrity during frequent handling, high-speed machine cycles, and exposure to wet concrete mixtures, significantly reducing the need for frequent replacements. Their material properties also make them resistant to corrosion and chemical effects, ensuring stable performance across a variety of production environments.

Thermal Resistance for Steam Curing Applications

A standout feature of GMT pallets is their exceptional thermal resistance. Many modern block production facilities utilize steam curing to accelerate the hardening process of concrete blocks. GMT pallets can withstand high temperatures without warping or compromising structural integrity, ensuring consistent block shape and quality. This thermal resilience contributes to reduced production defects and enhances the reliability of the curing process.

Compatibility with Leading Block Machine Brands

GMT plastic pallets have demonstrated high compatibility across an extensive range of block machine brands. From industry leaders like HESS and MASA to manufacturers including ZENITH, HAREX, FRIMA, KVM, OMAG, REKERS, and PRENSOLAND, these pallets integrate seamlessly into existing production lines. This broad compatibility reduces the need for multiple pallet types, simplifying inventory management and streamlining operations in facilities that operate mixed-brand block machines.

Advantages of Using GMT Pallets in Production

Enhanced Efficiency and Reduced Downtime

The durable design and precise dimensions of GMT pallets improve production efficiency. Smooth surfaces allow for effortless stacking and handling, reducing the risk of block damage during transfer between machines or storage. Their lightweight yet sturdy construction enables faster machine cycles, contributing to higher overall output without compromising product quality.

Cost-Effectiveness in Long-Term Operations

While the initial investment in GMT pallets may be higher than traditional wooden or steel pallets, their long-term cost-effectiveness is undeniable. The extended service life reduces the frequency of replacements, cutting both material costs and associated labor. Moreover, their adaptability across different machine types allows facilities to standardize pallet use, achieving operational economies of scale and minimizing the complexity of maintenance and storage.

Maintenance and Care for GMT Pallets

Cleaning and Inspection Protocols

To maximize the lifespan of GMT pallets, regular maintenance is essential. Pallets should be cleaned daily to remove concrete residue or debris. Periodic inspections help identify signs of wear, cracking, or minor deformation early, allowing timely repairs that prevent more serious issues. A combination of daily visual checks and detailed monthly inspections is recommended for optimal pallet upkeep.

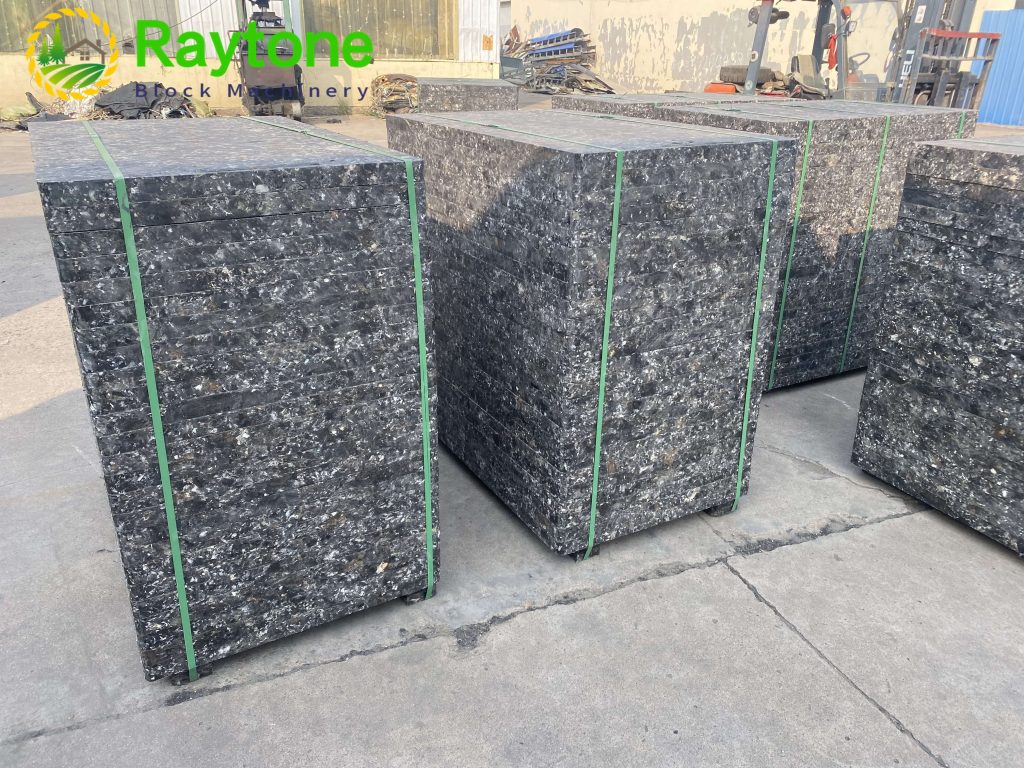

Storage and Handling Best Practices

Proper storage and handling are key to extending the service life of GMT pallets. When not in use, pallets should be stored in a clean, dry area away from direct sunlight to prevent UV damage. Pallets should be stacked carefully to avoid excessive weight on lower units, which could cause deformation. Training operators in proper lifting techniques and the use of handling equipment further reduces the risk of damage during transportation and handling.

Addressing Common Issues

Despite their durability, GMT pallets may encounter minor issues, such as surface scratches, slight warping, or wear at contact points. Most of these problems are easily remedied with simple maintenance. Minor warping can often be corrected using moderate heat and pressure, while surface scratches can be smoothed to prevent concrete adhesion. Maintaining a troubleshooting guide and repair kit ensures that production is not interrupted by minor pallet issues.

Conclusion

GMT pallets represent a versatile, durable, and highly efficient solution for block and brick production facilities. Their customizable dimensions, superior material properties, and compatibility with major block machine brands make them an indispensable tool in modern block-making operations. By implementing proper maintenance and handling practices, manufacturers can maximize pallet lifespan, reduce operational costs, and maintain consistent high-quality block production.

Contact Us

Enhance your block production line with GMT pallets from Raytone Machinery. Our expertise in block machines, brick pallets, and production line accessories ensures you receive tailored solutions that meet your operational needs. Reach out to us today at hazel@raytonechina.com to discuss how GMT pallets can improve your efficiency, reduce costs, and optimize your block production process.