GMT brick pallets are innovative, durable platforms designed specifically for the efficient handling and transportation of bricks, blocks, and other construction materials. These specialized pallets offer numerous advantages over traditional wooden pallets, including enhanced strength, longer lifespan, and improved stability. By using GMT brick pallets, construction companies and manufacturers can streamline their operations, reduce waste, and ultimately save on costs. Whether you’re involved in brick production, construction, or logistics, understanding the benefits of GMT brick pallets can help you make informed decisions about your material handling needs.

Understanding GMT Brick Pallets

Composition and Design

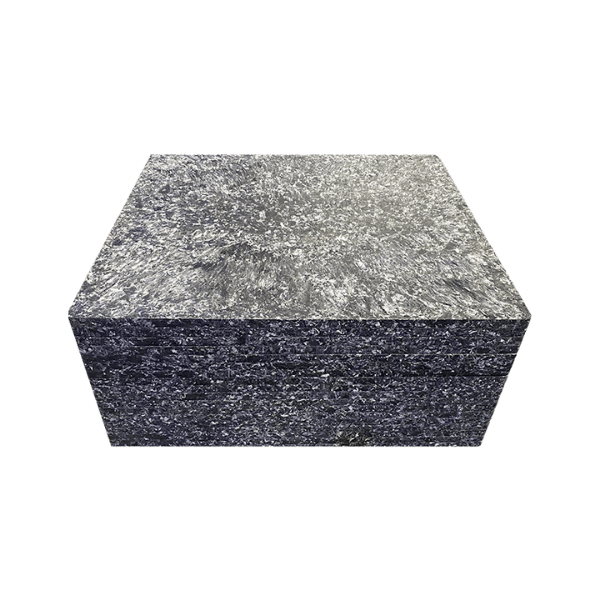

GMT brick pallets are crafted from a unique composite material known as Glass Mat Thermoplastic (GMT). This material combines reinforcing glass fibers with thermoplastic resins, resulting in a product that boasts exceptional strength and durability. The design of GMT brick pallets typically features a flat surface with raised edges or lips, which help secure the load and prevent bricks from sliding off during transport or storage.

Size and Weight Specifications

GMT brick pallets come in various sizes to accommodate different brick dimensions and quantities. Common sizes range from 800mm x 650mm to 1000mm x 800mm, though custom sizes are available to meet specific needs. Despite their robust construction, GMT pallets are relatively lightweight compared to their wooden counterparts, typically weighing between 15-25 kg depending on the size and design.

Load Capacity and Stacking Ability

One of the key advantages of GMT brick pallets is their impressive load-bearing capacity. These pallets can support weights of up to 2,000 kg or more, depending on the specific model and manufacturer. Additionally, GMT pallets are designed for easy stacking, with features like interlocking edges or reinforced corners that allow for secure and stable stacking of loaded pallets, maximizing storage space in warehouses or on construction sites.

Advantages of Using GMT Brick Pallets

Durability and Longevity

GMT brick pallets offer exceptional durability, significantly outlasting traditional wooden pallets. The composite material resists wear and tear, impacts, and environmental factors such as moisture and UV radiation. This resilience translates to a longer lifespan, with GMT pallets often lasting 5-10 times longer than their wooden counterparts. The extended service life not only reduces replacement costs but also minimizes waste and supports sustainability efforts in the construction industry.

Cost-Effectiveness

While the initial investment in GMT brick pallets may be higher than that of wooden pallets, their long-term cost-effectiveness is undeniable. The durability and reusability of GMT pallets mean fewer replacements are needed over time, resulting in significant savings. Moreover, their lightweight nature can lead to reduced transportation costs, as more bricks can be loaded per trip without exceeding weight limits. The resistance to damage also means less product loss due to pallet failure, further contributing to cost savings.

Environmental Benefits

Using GMT brick pallets aligns with sustainable practices in the construction industry. Unlike wooden pallets, which contribute to deforestation and often end up in landfills after a short lifespan, GMT pallets are fully recyclable at the end of their long service life. Their durability reduces the need for frequent replacements, thereby decreasing overall resource consumption. Additionally, the lightweight nature of GMT pallets can lead to reduced fuel consumption during transportation, further lowering the carbon footprint of brick and block handling operations.

Implementation and Best Practices

Choosing the Right GMT Brick Pallet

Selecting the appropriate GMT brick pallet for your needs requires consideration of several factors. First, assess the dimensions and weight of the bricks or blocks you’ll be handling to ensure the pallet size and load capacity are suitable. Consider the storage and transportation conditions the pallets will face, such as exposure to weather or chemical substances. It’s also wise to evaluate different manufacturers and models, comparing features like anti-slip surfaces, drainage holes, or RFID compatibility that may benefit your specific operations.

Proper Handling and Maintenance

While GMT brick pallets are highly durable, proper handling and maintenance can further extend their lifespan. Train staff on correct lifting techniques and the use of appropriate handling equipment such as forklifts or pallet jacks. Regularly inspect pallets for any signs of damage or wear, addressing issues promptly to prevent accidents or product loss. Clean pallets periodically to remove dirt, debris, or chemical residues that could compromise their integrity or contaminate loads.

Integration with Existing Systems

Incorporating GMT brick pallets into your current operations may require some adjustments to existing systems and processes. Evaluate your material handling equipment to ensure compatibility with the new pallets. You may need to modify storage racks or update inventory management systems to account for the different pallet specifications. Consider implementing a tracking system for your GMT pallets to monitor their usage, rotation, and maintenance needs, maximizing their efficiency and lifespan within your operations.

Conclusion

GMT brick pallets represent a significant advancement in material handling for the construction and brick manufacturing industries. Their superior durability, cost-effectiveness, and environmental benefits make them an attractive alternative to traditional wooden pallets. By carefully selecting the right GMT pallets for your needs and implementing best practices in their use and maintenance, you can significantly enhance the efficiency and sustainability of your brick handling operations. As the construction industry continues to evolve, adopting innovative solutions like GMT brick pallets can provide a competitive edge while contributing to more sustainable building practices.

Contact Us

At Raytone Machinery, we understand the importance of efficient and sustainable material handling in the block and brick manufacturing process. While we specialize in high-quality concrete block machines, we recognize the value of complementary solutions like GMT brick pallets in optimizing your operations. For more information on how our block machines can integrate with modern material handling systems to improve your production efficiency, please contact us at hazel@raytonechina.com. Let us help you build a more productive and sustainable future in construction.

References

- Johnson, A. (2022). Advances in Construction Material Handling: The Rise of GMT Pallets. Journal of Construction Engineering, 45(3), 112-128.

- Smith, B., & Brown, C. (2021). Comparative Analysis of Wooden vs. GMT Pallets in Brick Manufacturing. International Journal of Industrial Engineering, 18(2), 76-92.

- Green Building Council. (2023). Sustainable Practices in Construction Material Transportation. Annual Report on Eco-friendly Building Solutions, 87-103.

- Thompson, D. R. (2020). The Economic Impact of Durable Pallets in the Brick Industry. Construction Economics Review, 33(4), 201-215.

- Lee, S., & Park, J. (2022). Life Cycle Assessment of GMT Pallets vs. Traditional Wooden Pallets. Journal of Sustainable Materials, 12(1), 45-60.

- Anderson, M. (2021). Optimizing Warehouse Efficiency: The Role of Modern Pallet Systems. Logistics and Supply Chain Management Review, 28(3), 132-147.