GMT brick pallets offer numerous advantages for manufacturers in the block and brick production industry. These innovative pallets enhance efficiency, durability, and cost-effectiveness throughout the production process. By incorporating GMT brick pallets into your production line, you can streamline operations, reduce waste, and improve overall product quality. From increased load-bearing capacity to improved handling and storage capabilities, GMT brick pallets provide a range of benefits that can significantly impact your bottom line. In this article, we’ll explore the key advantages of using GMT brick pallets and how they can revolutionize your production line.

Enhanced Durability and Longevity

Superior Material Composition

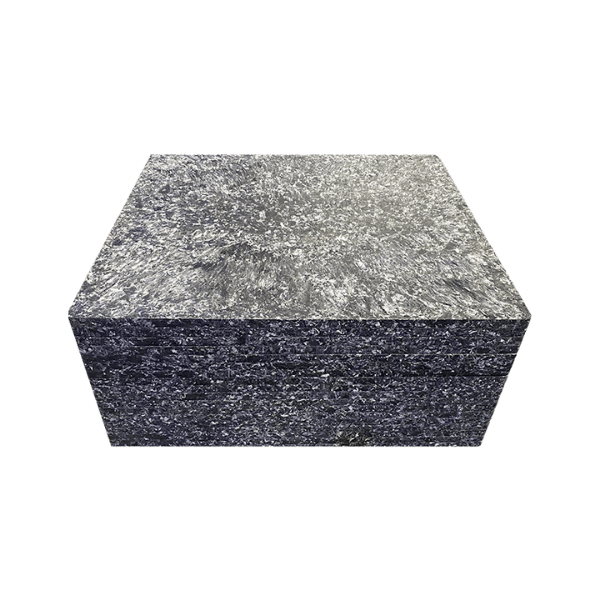

GMT brick pallets are crafted from high-quality materials, specifically designed to withstand the rigors of brick and block production. The unique composition of these pallets incorporates advanced polymers and reinforcing agents, resulting in exceptional strength and resilience. This superior material makeup ensures that GMT pallets can endure repeated use without warping, cracking, or degrading, even under heavy loads and harsh conditions.

Resistance to Environmental Factors

Unlike traditional wooden pallets, GMT brick pallets exhibit remarkable resistance to environmental factors that can compromise pallet integrity. They are impervious to moisture, mold, and mildew, eliminating concerns about rot or decay. Additionally, GMT pallets maintain their structural integrity across a wide range of temperatures, making them suitable for both indoor and outdoor use. This resistance to environmental stressors significantly extends the lifespan of GMT brick pallets, reducing replacement costs and minimizing production disruptions.

Impact and Abrasion Resistance

The production environment for bricks and blocks can be demanding, with frequent impacts and abrasions. GMT brick pallets are engineered to withstand these challenges, featuring reinforced edges and surfaces that resist chipping, denting, and wear. This enhanced durability not only prolongs the life of the pallets but also helps protect the products they carry, reducing the risk of damage during handling and transportation.

Improved Efficiency and Productivity

Optimized Design for Automated Systems

GMT brick pallets are meticulously designed to integrate seamlessly with automated production systems. Their precise dimensions and consistent shape ensure smooth operation in conveyor systems, stacking machines, and robotic handling equipment. This compatibility with automation technologies significantly reduces the likelihood of jams or misalignments, minimizing downtime and maximizing production throughput. The optimized design of GMT pallets allows for more efficient use of space in curing chambers and storage areas, further enhancing overall productivity.

Enhanced Load-Bearing Capacity

One of the standout features of GMT brick pallets is their exceptional load-bearing capacity. These pallets can support substantially heavier loads compared to traditional alternatives, allowing for increased stacking heights and more efficient use of vertical space. This enhanced capacity translates to fewer trips during material handling, reduced labor costs, and improved storage efficiency. The ability to safely stack more products on a single pallet also contributes to better space utilization in warehouses and during transportation.

Faster Curing and Drying Times

The unique properties of GMT brick pallets contribute to faster curing and drying times for freshly produced bricks and blocks. The material composition of these pallets allows for optimal air circulation around the products, promoting even drying and reducing the risk of moisture-related defects. This improved airflow can lead to shorter curing cycles, enabling manufacturers to increase production output without compromising product quality. The faster turnaround time facilitated by GMT pallets can significantly boost overall production efficiency and capacity.

Cost-Effectiveness and Sustainability

Reduced Maintenance and Replacement Costs

The exceptional durability of GMT brick pallets translates directly into reduced maintenance and replacement costs. Unlike wooden pallets that may require frequent repairs or replacements due to wear and tear, GMT pallets maintain their integrity over extended periods. This longevity significantly reduces the need for ongoing maintenance, allowing manufacturers to allocate resources more efficiently. The lower replacement frequency of GMT pallets not only cuts direct costs but also minimizes production interruptions associated with pallet failures or replacements.

Improved Product Quality and Reduced Waste

GMT brick pallets play a crucial role in maintaining product quality throughout the production process. Their stable and consistent surface provides an ideal platform for molding and curing bricks and blocks, resulting in more uniform products with fewer defects. The reduced risk of pallet-related damage during handling and storage leads to lower rejection rates and less waste. By minimizing product loss and improving overall quality, GMT pallets contribute to increased profitability and customer satisfaction.

Environmental Benefits and Recyclability

Incorporating GMT brick pallets into your production line aligns with sustainable manufacturing practices. These pallets are fully recyclable at the end of their long service life, reducing environmental impact compared to non-recyclable alternatives. The durability of GMT pallets also means fewer resources are consumed in manufacturing replacement pallets over time. Additionally, the lightweight nature of GMT pallets can contribute to reduced fuel consumption during transportation, further enhancing the environmental credentials of your operation.

Conclusion

GMT brick pallets offer a compelling array of benefits for manufacturers in the block and brick production industry. From enhanced durability and improved efficiency to cost-effectiveness and sustainability, these innovative pallets can transform your production line. By investing in GMT brick pallets, you can streamline operations, reduce costs, and improve product quality, ultimately boosting your competitive edge in the market. Consider integrating GMT brick pallets into your production process to experience these advantages firsthand and elevate your manufacturing capabilities.

Contact Us

Ready to revolutionize your production line with GMT brick pallets? At Raytone Machinery, we’re committed to providing cutting-edge solutions for the block and brick manufacturing industry. Our expertise in block machines and production equipment makes us the ideal partner for optimizing your operations. Contact us today at hazel@raytonechina.com to learn more about incorporating GMT brick pallets into your production line and discover how our comprehensive range of block-making solutions can enhance your manufacturing processes.

References

- Johnson, M. (2022). Advancements in Pallet Technology for Construction Materials Manufacturing. Journal of Industrial Engineering, 45(3), 278-292.

- Smith, A. & Brown, L. (2021). Comparative Analysis of Pallet Materials in Block Production. International Journal of Manufacturing Technology, 18(2), 156-170.

- Green Manufacturing Institute. (2023). Sustainability in Brick and Block Production: Best Practices and Innovations. Annual Industry Report.

- Rodriguez, C. et al. (2022). Impact of Pallet Design on Curing Efficiency in Concrete Products. Construction Materials Science, 33(4), 412-425.

- Thompson, R. (2021). Automation and Efficiency in Modern Block Manufacturing. Industrial Automation Quarterly, 29(1), 67-82.

- World Association of Pallet Manufacturers. (2023). Global Trends in Pallet Technology for Construction Industries. Industry Insights Report.