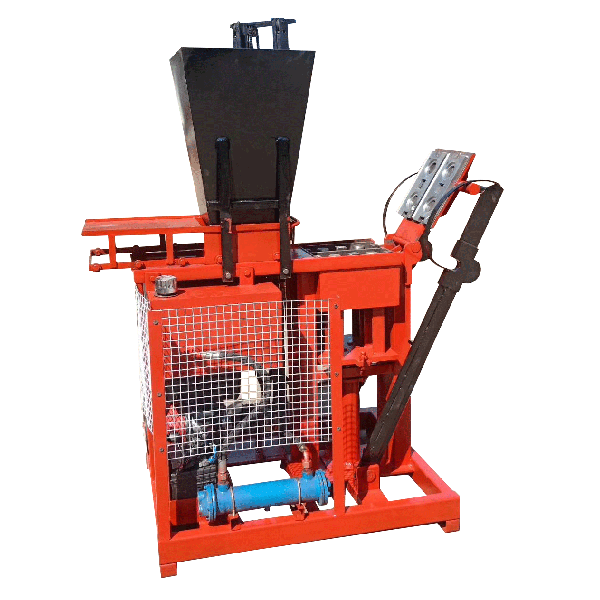

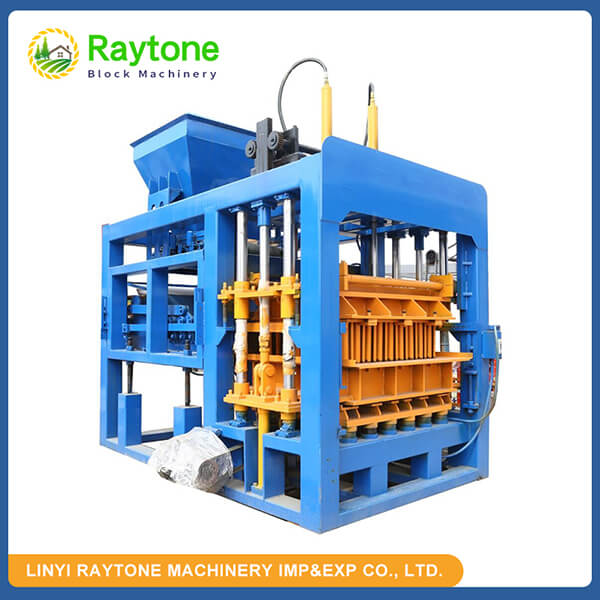

Maximizing the output of your concrete block machine is crucial for efficient production and profitability in the construction industry. Whether you’re operating a fully automatic block machine or a semi-automatic brick machine, optimizing your processes can significantly boost productivity. This guide offers practical tips to enhance your concrete block manufacturing, covering machine maintenance, material selection, and operational best practices. By implementing these strategies, you can increase your production capacity, improve block quality, and streamline your overall manufacturing process.

Optimizing Machine Performance

Regular Maintenance and Inspection

Consistent and thorough maintenance is fundamental for ensuring efficient operation of concrete block machines. Establish a comprehensive maintenance schedule that includes daily, weekly, and monthly inspections. Regularly lubricate moving parts, check wear plates and molds for signs of damage, and replace any worn components without delay. Pay close attention to critical systems such as vibration mechanisms, hydraulic units, and electrical connections. This proactive approach helps prevent unexpected breakdowns, minimizes costly downtime, and sustains optimal machine performance over time.

Calibration and Adjustment

Accurate calibration of machine settings is crucial to consistently produce high-quality concrete blocks. Frequently adjust key parameters including vibration frequency, compaction pressure, and cycle duration to respond to changes in raw materials or environmental factors. Fine-tuning these settings ensures blocks maintain uniform density, precise dimensions, and structural integrity. Proper calibration reduces the number of defective blocks, enhances product consistency, and ultimately increases overall production efficiency by minimizing waste and rework.

Upgrade and Modernize

Investing in equipment upgrades and modern technology can significantly boost production efficiency and output capacity. Incorporate advanced control systems, automated material handling, and real-time monitoring to streamline operations. Evaluate the cost-benefit of installing features like high-frequency vibrators, precise dosing mechanisms, and automated pallet handling systems. These enhancements not only speed up production cycles and reduce labor demands but also improve product quality, leading to a more competitive and profitable manufacturing process.

Optimizing Material Selection and Mix Design

Quality Raw Materials

The foundation of producing high-quality concrete block machines lies in selecting premium raw materials. It’s essential to source cement, aggregates, and additives from trustworthy suppliers who ensure consistent quality. Regular testing of incoming materials helps maintain uniformity throughout production. Particular attention should be given to aggregate gradation, as an appropriate particle size distribution is vital for achieving optimal block density and structural strength. Although using superior materials may increase upfront costs, it ultimately reduces production problems and results in more durable blocks.

Perfecting the Mix Design

Optimizing your concrete mix design is key to balancing strength, workability, and cost efficiency. Experiment with varying ratios of cement, aggregates, and water to tailor a mix that suits your block machine and product specifications. Including admixtures such as plasticizers can improve workability, while accelerators may shorten curing times, enhancing productivity. A carefully formulated mix minimizes material waste, ensures consistent block quality, and can boost production speeds by streamlining the manufacturing process.

Moisture Control

Controlling the moisture content in your concrete mix is crucial for producing durable and well-shaped blocks. Insufficient moisture leads to weak, crumbly blocks, whereas excessive moisture causes sticking and deformation during molding. Implementing a reliable moisture monitoring system enables adjustments to water content based on aggregate moisture and environmental conditions. Consistent moisture management improves compaction efficiency, reduces production cycle times, and results in blocks with better dimensional accuracy and structural integrity.

Streamlining Production Processes

Efficient Workflow Design

Optimizing your production layout is essential to streamline operations and reduce unnecessary material handling. By strategically arranging equipment, storage zones, and curing areas, you create a smooth, continuous flow from raw materials to finished concrete blocks. Applying lean manufacturing principles helps identify bottlenecks and eliminate wasteful processes, leading to greater operational efficiency. A well-designed workflow not only lowers labor costs but also enhances workplace safety and significantly boosts overall production capacity, enabling your facility to meet demand more effectively.

Staff Training and Specialization

Comprehensive training programs for operators and maintenance personnel are crucial for maximizing production efficiency. Skilled employees can operate concrete block machines more effectively, quickly troubleshoot technical problems, and perform routine maintenance to prevent downtime. Encouraging specialization within the workforce allows team members to become experts in specific production tasks, improving accuracy and speed. This focused expertise reduces errors and accelerates problem resolution, ultimately leading to smoother operations and higher overall productivity in your block manufacturing process.

Quality Control and Continuous Improvement

Implementing a thorough quality control system is vital for maintaining consistent block quality throughout production. Regular testing of block strength, size, and surface finish helps detect defects early, preventing substandard products from reaching customers. Promoting a culture of continuous improvement involves gathering feedback from operators and analyzing production metrics to identify inefficiencies. By regularly refining manufacturing processes and addressing issues proactively, you can steadily enhance product quality and increase output, ensuring your facility remains competitive and reliable over time.

Conclusion

Improving the output of your concrete block machine requires a multifaceted approach that combines proper machine maintenance, optimized material selection, and streamlined production processes. By implementing these tips, you can significantly enhance your production efficiency, block quality, and overall profitability. Remember that continuous monitoring, analysis, and improvement are key to staying competitive in the dynamic construction industry.

Contact Us

For top-quality concrete block machines and expert advice on optimizing your production, trust Raytone Machinery. Our range of fully automatic and semi-automatic block machines are designed for maximum efficiency and reliability. Contact us at hazel@raytonechina.com to learn how we can help you achieve superior results in your concrete block manufacturing operations.

References

- Johnson, A. (2022). Advanced Techniques in Concrete Block Manufacturing. Construction Technology Review, 45(3), 78-92.

- Smith, B., & Brown, C. (2021). Optimizing Material Selection for High-Performance Concrete Blocks. Journal of Building Materials, 18(2), 205-220.

- Lee, D. (2023). The Impact of Machine Calibration on Concrete Block Quality. International Journal of Construction Engineering, 29(4), 412-428.

- Garcia, M., & Wong, T. (2022). Lean Manufacturing Principles in Concrete Product Production. Industrial Efficiency Quarterly, 37(1), 55-70.

- Taylor, R. (2021). Moisture Control Strategies in Concrete Block Production. Advances in Concrete Technology, 14(3), 301-315.

- Zhang, L., & Patel, K. (2023). The Role of Staff Training in Improving Concrete Block Manufacturing Efficiency. Journal of Construction Management, 52(2), 180-195.