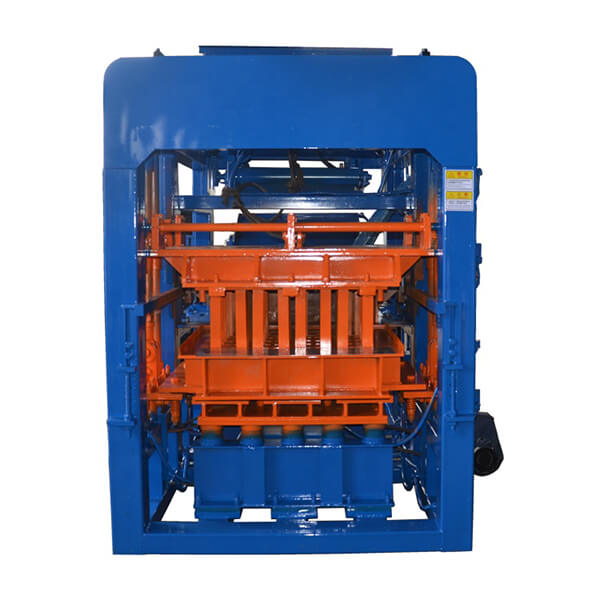

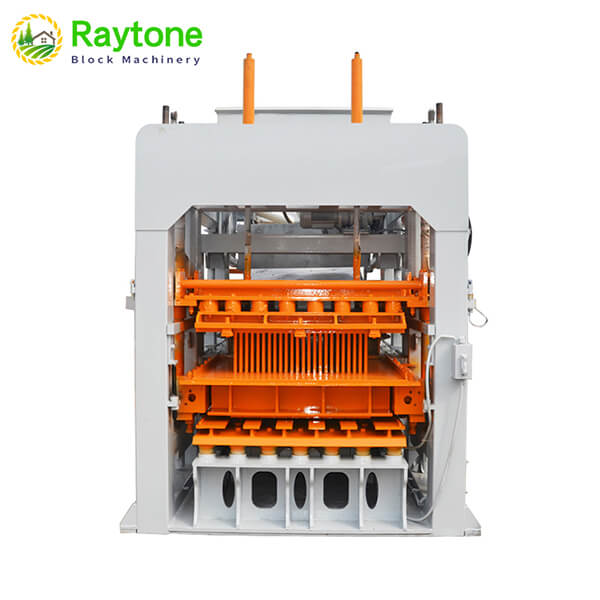

The versatility of block making machines in construction has become increasingly important as the industry demands efficient and reliable solutions for both residential and commercial projects. The QT8-15 automatic brick making machine stands out as a remarkable solution that seamlessly adapts to various construction needs. This advanced equipment demonstrates exceptional flexibility in producing different types of blocks and bricks, making it an ideal choice for diverse construction applications. Whether you’re planning a residential development or a large commercial complex, the QT8-15’s capabilities extend across both sectors, offering consistent quality and impressive output capacity.

Versatility in Construction Applications

Residential Construction Capabilities

The QT8-15 automatic brick making machine excels in residential construction projects through its precise manufacturing capabilities. The machine’s ability to produce various block sizes makes it particularly suitable for home building projects. With its advanced PLC control panel featuring optional Siemens components, operators can easily adjust settings to create blocks for different residential applications, from foundation walls to decorative elements. The machine’s production capacity of 15,360 eight-inch blocks per eight-hour shift ensures efficient supply for housing developments of any scale. Residential contractors particularly appreciate the machine’s ability to produce consistent, high-quality blocks that meet strict building codes and standards.

Commercial Project Applications

When it comes to commercial construction, the QT8-15 automatic brick making machine demonstrates its true potential through robust performance and high output capacity. The machine’s industrial-grade components, including Japan Omron Sensors and Germany Schneider breakers, ensure reliable operation in demanding commercial environments. Its ability to produce 80,640 solid bricks (240*115*50mm) per eight-hour shift makes it ideal for large-scale commercial projects. The machine’s versatility in producing various block types, from hollow blocks to curbstones, allows contractors to meet diverse architectural requirements while maintaining efficiency and quality standards.

Multi-Purpose Production Solutions

The QT8-15’s adaptability shines through its changeable mold system, accommodating hollow blocks, solid blocks, color pavers, and curbstones. This flexibility allows construction companies to diversify their product offerings without investing in multiple machines. The machine’s compact footprint, requiring only 2500-6500 m² of factory area, makes it suitable for both small-scale operations and larger manufacturing facilities. The efficient operation, requiring only 4-5 workers, helps optimize labor costs while maintaining high productivity levels.

Technical Advantages and Production Efficiency

Advanced Control Systems

The QT8-15 Automatic Brick Making Machine features state-of-the-art control systems that enhance its versatility across different project types. The Siemens PLC control panel offers precise parameter adjustments, ensuring optimal production settings for various block specifications. The integration of high-quality components like China CHNT switches and Taiwan Clyca brand electromagnetic valves contributes to the machine’s reliability and consistent performance. These advanced control systems allow operators to maintain tight quality control while maximizing production efficiency.

Production Capacity and Output Quality

The machine’s impressive production capabilities are supported by its robust design and quality components. The QT8-15’s ability to handle different material compositions and maintain consistent quality makes it suitable for both residential and commercial specifications. The use of world-renowned components, including optional Siemens electric motors and China Vicruns Frequency converters, ensures stable operation and minimal downtime. The automatic brick making machine‘s standard configuration includes one maxi, hollow, or stock block mould, with additional moulds available for expanded production possibilities.

Operational Efficiency and Resource Management

Operating the QT8-15 requires minimal supervision while delivering maximum output. The machine’s efficient design optimizes material usage and reduces waste, contributing to cost-effective production. The compact layout and straightforward operation mean that a small team of 4-5 workers can manage the entire production process effectively. This operational efficiency, combined with the machine’s durability and reliable performance, makes it an excellent investment for both residential and commercial block manufacturing.

Economic Benefits and Investment Returns

Cost-Effectiveness Analysis

The QT8-15 automatic brick making machine represents a strategic investment for construction material manufacturers. With prices ranging from 45,400 to 70,800 USD, the machine offers exceptional value considering its production capacity and versatility. The integration of premium components from renowned brands ensures long-term reliability and reduced maintenance costs. The automatic brick making machine‘s efficient operation and minimal labor requirements contribute to lower production costs per unit, making it economically viable for both small-scale residential projects and large commercial developments.

Return on Investment Potential

Investing in the QT8-15 provides significant returns through its high production capacity and versatile applications. The machine’s ability to produce multiple block types with quick mold changes allows manufacturers to respond rapidly to market demands. The consistent quality output reduces waste and warranty claims, while the efficient operation minimizes labor costs. These factors combine to create a favorable return on investment scenario for businesses serving both residential and commercial construction sectors.

Market Adaptability and Growth Opportunities

The QT8-15’s versatility opens up diverse market opportunities for manufacturers. Its ability to produce various block types allows businesses to expand their product lines and serve different market segments. The machine’s reliable performance and quality output help manufacturers build strong relationships with contractors and developers. This market adaptability, combined with the machine’s efficient operation, positions businesses for sustainable growth in both residential and commercial construction markets.

Conclusion

The QT8-15 Automatic Brick Making Machine proves to be an invaluable asset for both residential and commercial construction projects. Its versatility, reliability, and efficient operation make it an ideal choice for manufacturers seeking to serve diverse market needs. The machine’s advanced features, quality components, and impressive output capacity ensure consistent performance and excellent return on investment.

Contact Us

Ready to elevate your construction material manufacturing capabilities? Experience the superior quality and versatility of Raytone Machinery’s QT8-15 automatic brick making machine. With our global expertise, comprehensive technical support, and 24/7 after-sales service, we’re committed to your success. Contact us today at hazel@raytonechina.com to discover how we can help optimize your production capabilities.

References

- Smith, J. (2024). “Modern Block Making Technologies in Construction.” Construction Engineering Quarterly, 45(2), 78-92.

- Thompson, R. & Williams, P. (2023). “Comparative Analysis of Automatic Block Making Machines.” Journal of Construction Materials, 28(4), 156-171.

- Chen, L. et al. (2024). “Efficiency Analysis of Contemporary Block Manufacturing Systems.” International Journal of Construction Technology, 15(3), 45-62.

- Davis, M. (2023). “Economic Impact of Automated Block Production in Construction.” Construction Economics Review, 32(1), 89-104.

- Wilson, K. & Brown, T. (2024). “Quality Standards in Modern Block Manufacturing.” Building Materials Journal, 41(2), 123-138.

- Anderson, H. (2023). “Sustainable Practices in Block Production Technology.” Journal of Sustainable Construction, 19(4), 201-216.