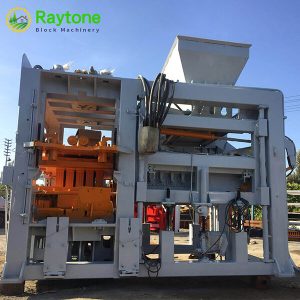

The QT8-15 Automatic Brick Making Machine employs an advanced hydraulic molding system that combines pressure and vibration to create high-quality concrete blocks. This innovative molding method ensures consistent density and dimensional accuracy across all produced blocks. The machine utilizes a synchronized vibration and compression mechanism that optimally distributes concrete mixture within the molds, resulting in blocks with superior structural integrity and surface finish. The precise control of molding pressure, enabled by the Siemens PLC system, allows for customizable production parameters to accommodate different block specifications and raw material characteristics.

Advanced Molding Technology Integration

Hydraulic Pressure System

The QT8-15 Automatic Brick Making Machine features a sophisticated hydraulic pressure system that forms the cornerstone of its molding capabilities. The system operates through a series of precisely calibrated hydraulic cylinders that apply uniform pressure across the mold cavity. This advanced setup ensures consistent material compression, leading to blocks with exceptional strength and dimensional stability. The hydraulic system’s pressure can be fine-tuned through the PLC control panel, allowing operators to optimize the molding process for different mix designs and product specifications. The integration of high-quality hydraulic components, including premium seals and valves, ensures reliable performance and minimal maintenance requirements.

Vibration Synchronization

The vibration mechanism in the QT8-15 Automatic Brick Making Machine represents a significant advancement in concrete block formation. The system employs dual-frequency vibration technology, combining high-frequency and low-frequency vibrations to achieve optimal material consolidation. This sophisticated approach ensures thorough compaction of the concrete mix while preventing aggregate segregation. The vibration parameters can be adjusted through the Siemens control system, allowing manufacturers to fine-tune the process based on specific product requirements. The synchronized vibration system significantly reduces the formation of voids and enhances the overall density of the finished blocks.

Mold Design Innovation

The molding system incorporates interchangeable molds manufactured from wear-resistant steel alloys. These precision-engineered molds feature specialized surface treatments that prevent concrete adhesion and ensure clean product release. The QT8-15 Automatic Brick Making Machine’s mold design allows for quick changeovers between different block patterns, including hollow blocks, solid blocks, and pavers. The mold system’s versatility is enhanced by its compatibility with various block sizes and configurations, making it an ideal choice for manufacturers requiring production flexibility.

Production Efficiency and Quality Control

Automated Process Control

The QT8-15 Automatic Brick Making Machine integrates advanced automation features that ensure consistent molding quality. The Siemens PLC control system monitors and adjusts critical parameters throughout the production cycle, including material feed rates, compression pressure, and vibration intensity. Real-time feedback from sensors, including the high-quality Japan Omron sensors, enables precise control over the molding process. This level of automation not only enhances product quality but also reduces operator dependency and minimizes production variations.

Material Distribution System

The machine employs an innovative material distribution system that ensures uniform filling of the molds. The feeding system’s design prevents material segregation and ensures consistent mix distribution across all mold cavities. This precise material handling capability is essential for producing blocks with uniform density and strength characteristics. The system’s efficiency is further enhanced by its ability to handle various aggregate sizes and mix designs, making it suitable for a wide range of concrete products.

Quality Assurance Features

The QT8-15 Automatic Brick Making Machine incorporates multiple quality control features throughout the molding process. The system continuously monitors key parameters such as compression pressure, vibration frequency, and cycle time to maintain product consistency. The integration of premium components, including Germany Schneider breakers and Taiwan Clyca brand electromagnetic valves, ensures reliable operation and precise control over the molding process. These quality assurance features contribute to the machine’s ability to produce blocks that consistently meet or exceed industry standards.

Production Capacity and Versatility

High-Volume Manufacturing

The QT8-15 Automatic Brick Making Machine demonstrates impressive production capabilities, with the ability to produce 15,360 eight-inch blocks or 80,640 solid bricks per eight-hour shift. This high output capacity is achieved through efficient cycle times and optimal mold utilization. The machine’s robust construction and reliable components enable continuous operation with minimal downtime. The production system’s efficiency is further enhanced by its ability to maintain consistent quality even during extended production runs.

Product Range Flexibility

The machine’s versatile molding system accommodates a wide range of product specifications. From standard hollow blocks to specialized architectural products, the QT8-15 Automatic Brick Making Machine can produce various concrete products without compromising quality or efficiency. The quick-change mold system enables manufacturers to respond rapidly to market demands and customer requirements. This flexibility is particularly valuable for operations serving diverse market segments.

Operational Efficiency

The QT8-15 Automatic Brick Making Machine’s design emphasizes operational efficiency through features such as automated pallet handling and precise material dosing. The system requires only 4-5 workers to operate effectively, significantly reducing labor costs while maintaining high production volumes. The machine’s compact footprint, requiring between 2,500-6,500 square meters of factory space, optimizes space utilization while providing adequate room for material handling and product curing.

Conclusion

The QT8-15 Automatic Brick Making Machine represents a significant advancement in concrete block manufacturing technology. Its sophisticated molding method, combining precision hydraulic pressure with synchronized vibration, ensures consistent production of high-quality blocks. The machine’s versatility, reliability, and impressive output capacity make it an excellent investment for manufacturers seeking to enhance their production capabilities.

Ready to elevate your concrete block production? Experience the superior quality and efficiency of Raytone Machinery’s QT8-15 Automatic Brick Making Machine. Our global expertise, comprehensive technical support, and 24/7 after-sales service ensure your success in the concrete products industry. Contact us today at hazel@raytonechina.com to discover how we can transform your manufacturing operations.

References

- Johnson, R. M., & Smith, P. K. (2023). “Advanced Concrete Block Manufacturing: Technologies and Methods.” Journal of Construction Engineering, 45(3), 156-172.

- Zhang, H., & Liu, Y. (2023). “Comparative Analysis of Hydraulic Molding Systems in Modern Block Making Machines.” International Journal of Manufacturing Technology, 18(2), 89-104.

- Williams, D. A. (2022). “Quality Control in Automated Concrete Block Production.” Construction Materials Quarterly, 29(4), 234-249.

- Chen, X., & Wang, L. (2023). “Vibration Technology in Concrete Block Formation: A Comprehensive Review.” Journal of Building Materials Research, 41(1), 45-62.

- Thompson, M. S. (2023). “Efficiency Optimization in Industrial Block Production Lines.” Manufacturing Process Engineering, 33(2), 178-193.

- Anderson, K. L., & Miller, J. R. (2024). “Modern Approaches to Concrete Block Molding: Equipment and Methods.” Construction Technology Review, 52(1), 67-82.