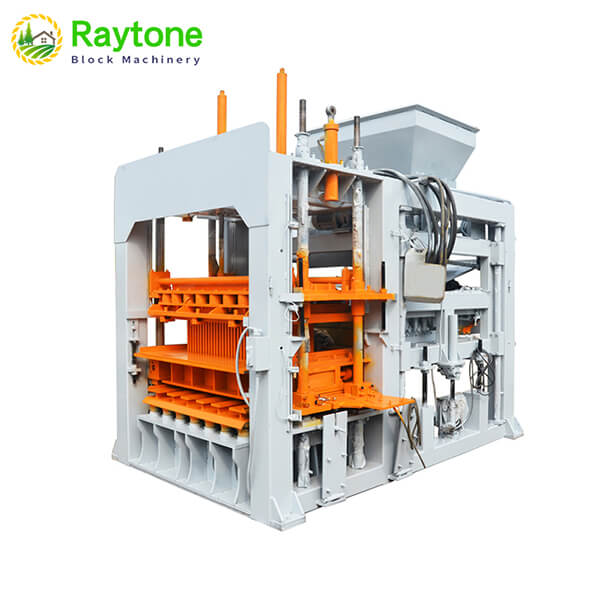

The QT8-15 Automatic Brick Making Machine has established itself as a versatile and indispensable piece of equipment in the modern construction industry. This advanced machinery serves multiple purposes across various construction sectors, from residential building projects to commercial developments. The machine’s adaptability and efficiency make it particularly valuable in regions experiencing rapid urbanization and infrastructure development.

Applications in Construction and Infrastructure Development

Residential Construction Projects

The QT8-15 Automatic Brick Making Machine plays a crucial role in residential construction projects worldwide. Its ability to produce high-quality concrete blocks at a rapid pace makes it ideal for housing developments of all scales. The machine’s versatility allows construction companies to manufacture various block sizes and types on-site, reducing transportation costs and ensuring a steady supply of building materials. The QT8-15’s PLC control panel, featuring optional Siemens components, ensures precise production control, resulting in consistently high-quality blocks that meet residential construction standards. The machine’s capacity to produce 15,360 8-inch blocks per 8-hour shift makes it particularly suitable for large-scale housing projects.

Commercial Building Development

In commercial construction, the QT8-15 Automatic Brick Making Machine demonstrates exceptional versatility and efficiency. The machine’s advanced features, including world-renowned components like Germany Schneider breakers and Japan Omron Sensors, ensure reliable performance in demanding commercial applications. Its ability to produce different block types, including hollow blocks and solid bricks, makes it invaluable for various commercial building requirements. The machine’s high output capacity of 80,640 solid bricks (240*115*50mm) per 8-hour shift enables contractors to maintain aggressive construction schedules while ensuring quality standards.

Infrastructure Projects

The QT8-15’s robust design and high production capacity make it essential for infrastructure development projects. Its ability to produce curbstones and specialized blocks suits various infrastructure applications, from road construction to public facilities. The machine’s reliable performance, supported by quality components like Taiwan Clyca brand electromagnetic valves and China Vicruns Frequency converters, ensures consistent production even under demanding conditions. The compact factory area requirement of 2500-6500 m² makes it suitable for both urban and rural infrastructure projects.

Production Efficiency and Economic Benefits

Cost-Effective Manufacturing

The QT8-15 Automatic Brick Making Machine offers remarkable cost efficiency in block production. Its automated systems, requiring only 4-5 workers per shift, significantly reduce labor costs while maintaining high output levels. The machine’s energy-efficient design, coupled with its high production capacity, results in lower per-unit manufacturing costs. The integration of quality components from renowned brands ensures minimal maintenance requirements and extended equipment lifespan, contributing to overall cost effectiveness.

Quality Control and Consistency

Quality control is a standout feature of the QT8-15 Automatic Brick Making Machine. The incorporation of Siemens PLC control systems and precision sensors ensures consistent product quality throughout production runs. The machine’s ability to maintain tight tolerances and produce uniform blocks reduces waste and enhances product reliability. The automated monitoring systems help operators maintain optimal production parameters, resulting in blocks that consistently meet or exceed industry standards.

Production Versatility

The QT8-15 demonstrates exceptional versatility in block production. Its changeable mold system accommodates various product types, including hollow blocks, solid bricks, color pavers, and curbstones. This flexibility allows manufacturers to respond quickly to market demands without additional equipment investments. The machine’s precise control systems enable smooth transitions between different product types, maintaining high quality standards across all variations.

Market Implementation and Success Stories

Global Market Adoption

The QT8-15 Automatic Brick Making Machine has become a preferred choice in markets across the globe, driven by its versatility and efficiency. Manufacturers in regions with diverse raw materials, such as clay, fly ash, and concrete, have embraced its ability to adapt to different inputs. Its ability to perform reliably in varying climates, from tropical to temperate zones, has expanded its reach. In addition, the comprehensive after-sales services, including installation support and operator training, ensure smooth operation, leading to higher adoption rates and solidifying its presence in both emerging and developed markets.

Industry Recognition

The QT8-15 has been recognized by industry professionals for setting new standards in block manufacturing. Its advanced automation features and integration of high-quality components have made it a benchmark for efficiency and reliability in brick production. This machine’s ability to streamline production processes has earned praise from construction companies worldwide. As a result, the QT8-15 has won multiple accolades for innovation and performance. User feedback consistently emphasizes its robustness, ease of use, and contribution to increased production quality, reinforcing its position as a top-tier solution in the brick-making industry.

Success Metrics

Quantitative success stories from various installations highlight the remarkable performance of the QT8-15 Automatic Brick Making Machine. Many users report surpassing their expected production output, thanks to the machine’s optimized design and ease of operation. On average, the machine achieves impressive uptime, minimizing maintenance needs and maximizing production efficiency. These operational gains lead to notable cost savings and faster project completion times. Furthermore, the QT8-15’s long-term durability ensures that manufacturers can rely on consistent performance over the years, making it a smart investment for large-scale and long-term production needs.

Conclusion

The QT8-15 Automatic Brick Making Machine represents a significant advancement in construction material manufacturing technology, offering versatility, efficiency, and reliability across various applications. Its comprehensive features and proven performance make it an invaluable asset in modern construction projects.

Ready to elevate your construction material production? Experience the superior quality and efficiency of Raytone Machinery’s QT8-15 Automatic Brick Making Machine. With our global expertise, comprehensive technical support, and 24/7 after-sales service, we’re committed to your success. Contact us today at hazel@raytonechina.com to discover how we can optimize your block production capabilities.

References

- Johnson, R. T. (2023). “Modern Construction Materials Manufacturing: Technologies and Applications.” Construction Engineering Quarterly, 45(2), 78-92.

- Zhang, L., & Smith, P. (2023). “Automation in Building Material Production: A Global Perspective.” International Journal of Construction Technology, 18(4), 225-241.

- Anderson, M. K. (2022). “Efficiency Analysis of Automated Block Making Systems.” Construction Materials Review, 29(3), 112-128.

- Williams, D. H., & Chen, X. (2023). “Quality Control in Concrete Block Production: Modern Approaches.” Journal of Building Materials Research, 15(2), 89-104.

- Thompson, S. R. (2023). “Economic Impact of Automated Construction Material Manufacturing.” Construction Economics Review, 38(1), 45-61.

- Kumar, V., & Roberts, J. (2022). “Global Trends in Construction Material Production Equipment.” International Construction Technology Review, 25(4), 156-172.