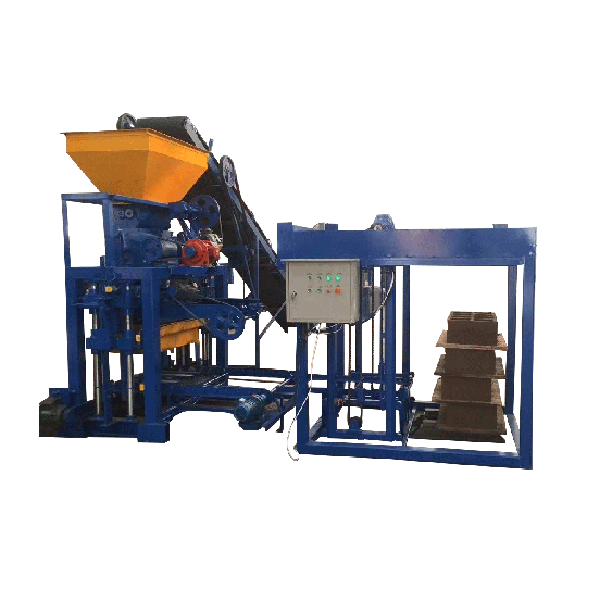

The QT4-35 Manual Brick Making Machine is one of the most user-friendly and practical models in the small and medium-size block production industry. With a compact structure and simple control system, it allows operators — even beginners — to start production quickly and efficiently.

Unlike fully automated systems that require technical expertise, the QT4-35’s manual hydraulic operation offers direct control over every stage of production, from feeding and molding to block ejection. Its ease of operation and flexible mold system make it a perfect choice for entrepreneurs, local builders, and construction material suppliers looking to start or expand their brick manufacturing business at a reasonable investment.

Key Features and Advantages of the QT4-35 Manual Brick Making Machine

1. User-Friendly Design

The QT4-35 is designed with simplicity and durability in mind. Its mechanical structure and manual hydraulic press allow smooth operation without complicated programming or electrical systems. Operators can easily control pressure, vibration, and compaction, ensuring every brick or block meets the desired density and strength.

2. Versatility in Product Range

With interchangeable moulds, this manual block making machine can produce various types of concrete products — including hollow blocks, solid bricks, paving stones, and curbstones. This flexibility enables small factories to serve different market needs without additional machines.

By changing moulds, users can easily shift production between construction blocks and decorative pavers, adapting to both residential and commercial projects.

3. Low Investment, High Profit

The QT4-35 offers one of the best cost-to-performance ratios among block machines in its category. Priced between USD 5,000 and 15,000, it provides a cost-effective entry into the cement block manufacturing industry.

Its manual operation reduces energy consumption and maintenance expenses, allowing faster returns on investment. For many startups, this model becomes the first step toward a sustainable brick-making business.

4. Compact and Efficient Layout

Thanks to its space-saving design, the QT4-35 can be installed in workshops as small as 40 m², with a total working area of around 200 m². This makes it an ideal solution for businesses with limited land resources or for on-site brick production projects in rural or remote areas.

5. Durable and Long-Lasting Structure

The machine is built with high-strength welded steel and precision-engineered components. The robust frame ensures stable performance during operation, while the hydraulic system delivers consistent pressure for uniform block density. With proper maintenance, the QT4-35 can operate reliably for many years.

Step-by-Step Operation Guide for the QT4-35 Block Machine

Step 1: Material Preparation

The process starts with preparing a well-proportioned mix of cement, sand, and aggregates. For stronger blocks, crushed stone or fly ash may be added. Uniform mixing is crucial to ensure consistent quality. Once mixed, the materials are loaded into the machine’s hopper manually.

Step 2: Mold Setup

Select the desired mold according to the block type. Whether producing 8-inch hollow blocks or paver bricks, mold installation takes only a few minutes. Before production, always check that the mold is properly aligned and lubricated to prevent sticking or deformation.

Step 3: Hydraulic Compaction

After feeding the material into the mold box, the operator manually activates the hydraulic lever to apply pressure. The vibration and compression process forms the bricks tightly and evenly. Operators can easily adjust pressure depending on block type and raw material composition.

Step 4: Brick Ejection and Pallet Transfer

When the compaction process is completed, the freshly formed blocks are ejected onto a pallet. They should be handled carefully to avoid damage before curing. The filled pallets are then moved to the curing area, where the blocks harden naturally or under controlled moisture conditions.

Maximizing Output and Productivity

Although the QT4-35 is a manual brick press, it can deliver remarkable production capacity when operated efficiently.

A skilled team of 4–5 workers can produce 2,500 to 3,300 hollow blocks or 10,000 solid bricks in one 8-hour shift. To maintain high output:

-

Organize raw materials in advance to avoid production interruptions.

-

Assign clear tasks to each worker (mixing, feeding, pressing, and pallet transfer).

-

Keep molds and hydraulic parts clean for consistent compaction quality.

With proper workflow management, the QT4-35 can easily meet local market demand for building materials while maintaining low operational costs.

Quality Control and Maintenance Tips

Ensuring Brick Quality

Quality starts with raw material selection and mixing. Use fresh cement and clean sand to prevent cracks and weak spots. Check each batch of blocks during production — if density or edges are inconsistent, adjust the hydraulic pressure or vibration time immediately.

Routine Maintenance

To ensure stable performance:

-

Clean the mold and hopper daily.

-

Lubricate all moving parts regularly.

-

Inspect hydraulic seals and hoses for leakage.

-

Replace worn-out components promptly.

Consistent maintenance helps extend the machine’s lifespan and keeps production running smoothly.

Applications of the QT4-35 Brick Making Machine

The QT4-35 model is suitable for various construction applications, including:

-

Residential buildings – wall blocks, load-bearing bricks.

-

Road construction – curbstones, paver bricks.

-

Community projects – schools, hospitals, low-cost housing.

-

On-site production – remote construction sites where electricity is limited.

Its manual operation and durable performance make it a popular choice for developing regions, construction startups, and local government housing programs.

Why Choose Raytone Machinery’s QT4-35?

As a professional brick making machine manufacturer, Raytone Machinery focuses on delivering reliable and affordable block production solutions. Our QT4-35 Manual Brick Moulding Machine is manufactured using precision engineering and strict quality control to ensure long-term performance and easy operation.

We provide:

-

Customized mold designs for different block sizes

-

Technical guidance and training for operators

-

Fast after-sales support and spare parts supply

-

Competitive factory prices with global shipping options

With more than 15 years of experience in the concrete block machine industry, Raytone Machinery has built trusted partnerships with clients in Africa, Asia, South America, and the Middle East.

Conclusion

The QT4-35 Manual Brick Making Machine combines affordability, reliability, and versatility — making it one of the best choices for small to medium-scale block manufacturers. Its easy operation, flexible mold system, and low maintenance needs make it ideal for anyone looking to start a brick production business with minimal risk and maximum control.

Whether for urban construction projects or rural housing development, the QT4-35 offers a practical and profitable path toward self-sufficient, sustainable brick manufacturing.

Contact Us

At Raytone Machinery, we are committed to providing professional solutions for your brick and block production business.

📧 Email: hazel@raytonechina.com

Raytone Machinery — Your Reliable Partner in Concrete Block Making.