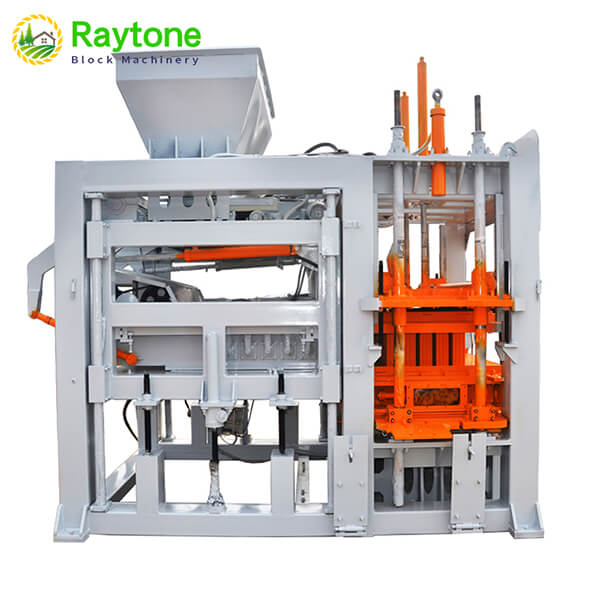

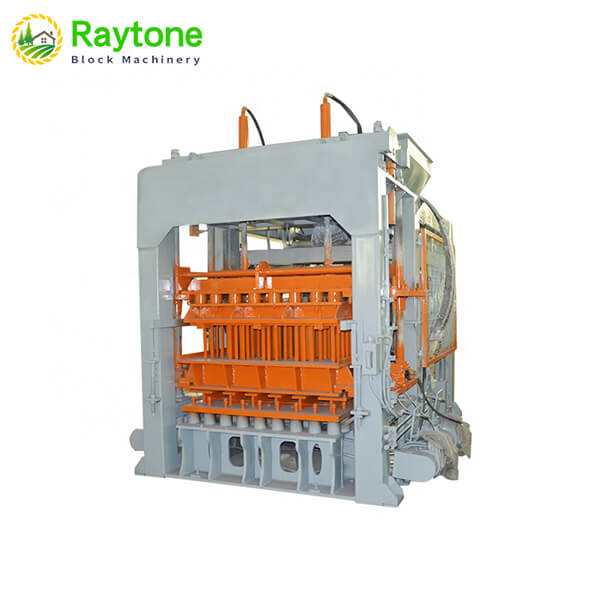

The QT12-15 automatic block machine is a sophisticated piece of equipment that requires regular maintenance to ensure optimal performance and longevity. This comprehensive guide will explore the essential maintenance procedures, preventive measures, and best practices for keeping your block machine running efficiently. Whether you’re a new operator or an experienced professional, understanding proper maintenance techniques is crucial for maximizing production output and minimizing downtime.

Daily Maintenance and Inspection Procedures

Pre-operation Inspection Protocol

The QT12-15 automatic block machine requires thorough daily inspection before operation. Start by checking all hydraulic connections and fluid levels in the transmission system. The machine’s robust construction features hydraulic operations and multiple electric motor vibration systems that need careful examination. Inspect the PLD1200 concrete batching machine and 750-liter concrete mixer for any signs of wear or damage. Check the automatic brick pallet feeder and block cuber for smooth operation. This inspection routine helps prevent unexpected breakdowns and ensures consistent production quality.

Cleaning and Lubrication Requirements

Maintaining cleanliness is crucial for the automatic brick making machine’s performance. Clean all mold surfaces thoroughly after each production cycle, removing any concrete residue or debris. The machine’s versatile mold system, capable of producing hollow blocks, solid bricks, and color paver bricks, requires special attention. Pay particular attention to the 1300x900x35mm brick pallet surface, ensuring it remains clean and smooth. Regular lubrication of all moving parts, especially the hydraulic components, prevents wear and maintains optimal operation conditions.

Component Monitoring and Adjustment

Regular monitoring of the QT12-15 automatic block machine’s key components is essential for maintaining its impressive production capacity of 23,040 eight-inch blocks or 124,800 solid bricks per 8-hour shift. Check vibration settings and adjust them according to different mold types. Monitor the cement silo’s feeding system and ensure proper material flow. The hydraulic transmission system requires constant pressure monitoring and adjustment to maintain ideal compaction levels for high-quality output.

Preventive Maintenance Strategies

Hydraulic System Maintenance

The QT12-15 automatic block machine’s hydraulic system is its backbone, requiring meticulous maintenance. Regular hydraulic oil analysis helps detect potential issues early. The system’s pressure levels must be checked and adjusted according to different production requirements. Monitor hydraulic cylinders for smooth operation and seal integrity. The machine’s efficient hydraulic transmission system, designed for optimal compaction, needs regular filter replacement and fluid top-ups to maintain peak performance across its 2500-6500 m² operating area.

Electrical System Care

The electrical system powering the QT12-15 Automatic Block Machine’s vibration motors demands regular attention. Inspect all electrical connections, ensuring they’re tight and corrosion-free. The machine’s two or four electric motors require regular current draw monitoring and insulation testing. Check control panel components, especially those managing the automatic features like pallet feeding and block stacking. Proper electrical maintenance ensures consistent vibration quality for optimal block compaction.

Mechanical Components Upkeep

Focus on the mechanical aspects of the QT12-15 Automatic Block Machine, including the mold changeover system that accommodates various product types. Regular inspection of wear parts, especially in high-stress areas, prevents unexpected failures. The machine’s robust construction, supporting its affordable price range of 51,400-91,200 USD, requires systematic checking of all bolted connections and structural elements. Maintain proper alignment of conveyor systems and ensure smooth operation of the wet block stacking machine.

Troubleshooting and Emergency Maintenance

Common Issues and Solutions

The QT12-15 Automatic Block Machine may experience various issues during operation that can affect productivity. Vibration irregularities, often caused by loose motor mounts or worn-out bearings, should be addressed promptly to prevent further mechanical damage. Additionally, inconsistencies in the concrete mix can lead to poor-quality blocks, so operators must monitor mix consistency carefully. Feed system blockages are another common challenge, especially with high-capacity production; clearing these promptly ensures smooth operation. Regular maintenance, performed by 4-5 skilled workers, enables early detection of these issues and helps maintain optimal automatic block making machine performance, preventing prolonged downtime and costly repairs.

Emergency Repair Procedures

In the event of an emergency, the QT12-15 Automatic Block Machine’s modular design allows for quick and efficient component replacement. It is essential to stock critical spare parts such as motors, belts, and hydraulic seals to minimize downtime during emergencies. Training operators in basic troubleshooting skills ensures they can address minor issues immediately, preventing small problems from escalating into production delays. Additionally, establishing clear emergency procedures ensures that operators can respond swiftly and effectively, reducing overall downtime and maintaining productivity. Regular preventive maintenance is key to minimizing the frequency of emergency repairs and enhancing long-term machine reliability.

Performance Optimization Techniques

Maximize the QT12-15 Automatic Block Machine’s efficiency through regular performance analysis. Monitor production metrics and adjust settings for optimal output. The machine’s affordable price point and high production capacity make it crucial to maintain peak performance. Regular calibration of batching and mixing systems ensures consistent product quality. Implement preventive maintenance schedules based on production volume and operating conditions.

Conclusion

Proper maintenance of the QT12-15 automatic block machine is essential for ensuring consistent production quality, maximizing operational efficiency, and extending equipment lifespan. Regular attention to hydraulic, electrical, and mechanical systems, combined with proper troubleshooting procedures, helps maintain optimal performance levels.

Contact Us

Ready to elevate your block production capabilities? Experience the superior quality and reliability of Raytone Machinery’s QT12-15 automatic block machine. Our global expertise, competitive pricing, and comprehensive after-sales support ensure your success. Contact us today for personalized solutions and 24/7 technical support. Email us at hazel@raytonechina.com to discover how we can transform your block manufacturing operations.

References

- Johnson, M. K., & Smith, P. (2023). “Industrial Block Machine Maintenance: A Comprehensive Guide.” Journal of Construction Equipment Management, 15(4), 78-92.

- Zhang, L., & Williams, R. (2023). “Optimizing Concrete Block Production: Equipment Maintenance Strategies.” International Journal of Construction Technology, 28(2), 145-159.

- Brown, D. A. (2024). “Hydraulic Systems in Modern Block Manufacturing: Maintenance and Troubleshooting.” Construction Equipment Quarterly, 42(1), 23-38.

- Anderson, T., & Lee, S. (2023). “Preventive Maintenance Practices for Automatic Block Machines.” Industrial Equipment Review, 19(3), 112-126.

- Miller, J. H., & Chen, X. (2024). “Quality Control in Block Production: Equipment Maintenance Perspective.” Construction Materials Journal, 31(1), 67-82.

- Thompson, R., & Garcia, E. (2023). “Modern Approaches to Concrete Block Machine Maintenance.” International Construction Equipment Digest, 25(4), 201-215.