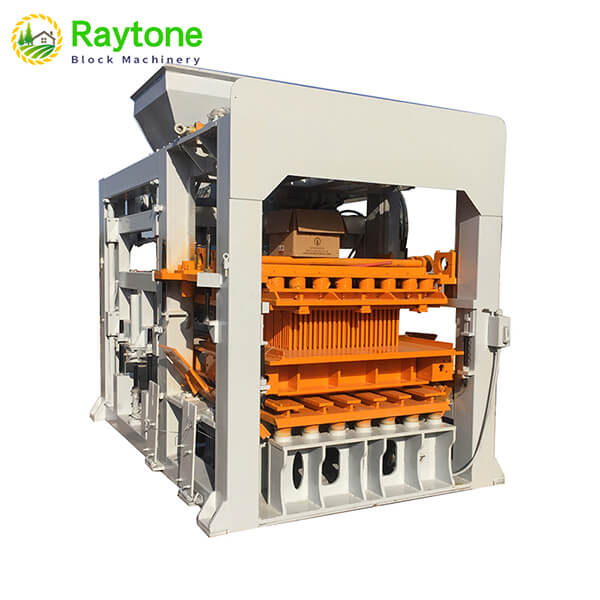

The global market for concrete block making machines is experiencing significant growth, driven by rapid urbanization, infrastructure development, and the increasing popularity of sustainable construction practices. These versatile machines, essential for producing high-quality concrete blocks efficiently, are in high demand across residential, commercial, and industrial sectors. The market is expected to expand further as emerging economies invest heavily in construction projects and developed nations focus on modernizing their infrastructure. Manufacturers like Raytone Machinery are at the forefront of this trend, offering innovative solutions that cater to diverse project requirements and contribute to the industry’s evolution.

Current Market Trends and Future Projections

Technological Advancements in Block Production

The concrete block manufacturing industry is undergoing significant technological advancements that are transforming production processes. Modern block making machines now feature automated control systems, precision molding capabilities, and real-time quality monitoring to ensure consistent output. These innovations help optimize resource use by reducing material waste and energy consumption. Additionally, manufacturers are increasingly prioritizing eco-friendly designs that minimize water usage and carbon footprint, aligning block production with broader environmental sustainability goals and regulatory requirements worldwide.

Increasing Demand for Customization

With construction projects becoming more architecturally diverse, the demand for customized concrete blocks is rising sharply. Block making machines that offer adjustable mold systems to create a variety of sizes, shapes, and surface textures are gaining traction. This flexibility allows builders and designers to meet unique aesthetic and structural requirements, especially in commercial and residential architectural projects. In response, manufacturers are developing modular machines that can be easily reconfigured, enabling fast adaptation to changing project demands and enhancing production versatility.

Market Expansion in Developing Regions

Developing regions across Asia, Africa, and Latin America represent rapidly growing markets for concrete block making machines. Factors such as accelerating urbanization, government-driven affordable housing programs, and expanding infrastructure investments are fueling demand. These areas offer manufacturers vast opportunities to tailor their equipment and services to local construction needs and budget constraints. By focusing on cost-effective, reliable, and easy-to-operate machines, suppliers can tap into these emerging markets, supporting sustainable development while expanding their global footprint.

Factors Influencing Market Growth

Sustainable Construction Practices

The global emphasis on sustainable construction is a significant factor driving growth in the concrete block making machine market. Concrete blocks are favored for their longevity, energy efficiency, and potential for recycling. Modern block making machines are designed to support these sustainability goals by enabling the use of recycled aggregates and materials. Additionally, energy-efficient production processes help reduce carbon emissions. This focus on green building standards appeals to environmentally conscious builders and developers seeking to minimize the ecological footprint of their construction projects.

Cost-Effectiveness and Efficiency

With rising construction costs worldwide, the efficiency and cost-effectiveness of block making machines have become increasingly important. These machines enable the rapid production of large volumes of consistent, high-quality blocks, significantly reducing labor costs and accelerating project timelines. On-site block production further minimizes transportation expenses and logistical complexities, making the machines highly attractive for large-scale and remote projects. This combination of speed, quality, and cost savings strengthens the machines’ appeal across various sectors of the construction industry.

Regulatory Support and Infrastructure Investments

Government regulations and policies play a crucial role in expanding the market for concrete block making machines. Many countries are enforcing stricter building codes that mandate the use of standardized, quality-assured concrete blocks, thus driving demand for advanced manufacturing equipment. Moreover, extensive infrastructure investments, including affordable housing programs and urban development projects, sustain consistent demand. These government-led initiatives create favorable market conditions for machine manufacturers and suppliers, facilitating steady growth and adoption of modern block production technologies.

Challenges and Opportunities in the Market

Addressing Skills Gap and Training Needs

As concrete block making machines evolve with more advanced features, the demand for skilled operators and maintenance staff increases. This skills gap poses a challenge for manufacturers and end-users alike. However, it also offers an opportunity for companies to differentiate themselves by providing thorough training programs, technical support, and easy-to-understand user manuals. Additionally, incorporating user-friendly control interfaces and remote diagnostics can simplify machine operation and troubleshooting, helping operators quickly adapt and maintain productivity with minimal downtime.

Adapting to Regional Market Needs

The global concrete block making machine market is characterized by diverse regional demands influenced by local construction methods, climate, and regulations. Manufacturers that successfully tailor their products to address these specific requirements gain a competitive advantage. This may involve designing machines with adjustable features, ruggedness for harsh climates, or compliance with local safety and quality standards. Offering customizable machine options allows businesses to better serve local markets, enhancing customer satisfaction and expanding their footprint in different geographical areas.

Embracing Digital Technologies

The adoption of digital technologies is revolutionizing the concrete block making machine industry by enabling smarter, more efficient operations. IoT-enabled machines equipped with real-time production monitoring, predictive maintenance alerts, and data analytics are transforming how manufacturers and users manage production. These innovations help reduce unexpected downtime, optimize maintenance schedules, and improve product quality. Companies that invest in digital integration can provide greater value through enhanced machine reliability, operational transparency, and informed decision-making, positioning themselves at the forefront of industry advancements.

Conclusion

The concrete block making machine market is experiencing robust growth, fueled by global construction trends and technological advancements. As urbanization accelerates and sustainability becomes a priority, the demand for efficient, versatile block production equipment is set to increase. Manufacturers who can offer innovative, cost-effective solutions that meet diverse market needs will thrive in this evolving landscape. The future of the industry looks promising, with ample opportunities for growth and innovation.

Contact Us

For high-quality concrete block making machines that meet your specific project needs, look no further than Raytone Machinery. Our range of advanced, efficient, and reliable block making solutions ensures excellent value and performance. Contact us at hazel@raytonechina.com to learn how we can support your construction projects with our state-of-the-art equipment.

References

- Global Concrete Block and Brick Manufacturing Market Report 2021.

- Construction Technology Trends: The Future of the Industry.

- Sustainable Building Materials: Innovations and Applications.

- Urbanization and Its Impact on Construction Industry Growth.

- The Role of Automation in Modern Construction Practices.

- Infrastructure Development in Emerging Markets: Challenges and Opportunities.