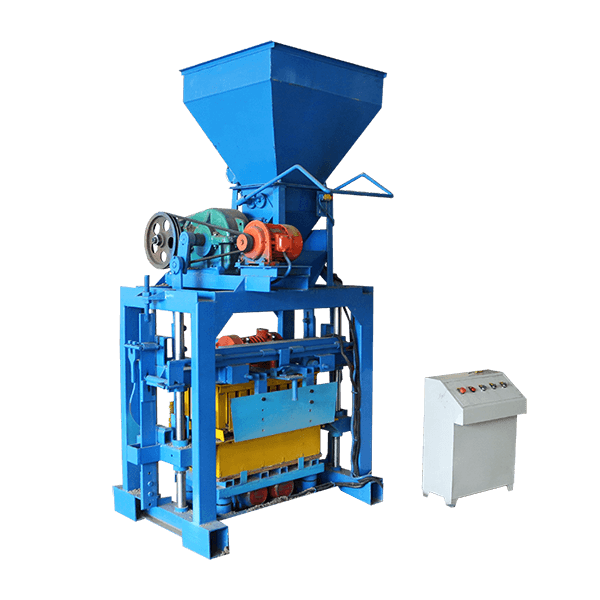

Manual block machines, like the QT4-35 manual brick making machine, offer impressive productivity for small to medium-sized construction projects. These versatile machines can produce 2,560 to 3,290 8-inch blocks in an 8-hour shift, depending on the efficiency of the operators and the specific mold used. While not as fast as fully automated systems, manual block machines provide a cost-effective solution for startups and smaller operations. Their productivity is further enhanced by their ability to produce various block types, including hollow blocks, solid bricks, pavers, and curbstones, simply by changing the mold. This flexibility allows manufacturers to meet diverse market demands efficiently.

Understanding Manual Block Machine Productivity

Factors Influencing Output

Several key factors influence the overall productivity of a manual block machine. Operator skill is fundamental – experienced workers can manage the process more efficiently and reduce errors. Material handling, including mixing and transporting raw materials, also plays a crucial role in maintaining a steady workflow. The curing process must be carefully controlled to ensure quality and consistency. Moreover, using high-quality raw materials contributes to stronger, more uniform blocks. Regular maintenance and precise machine setup help prevent downtime and sustain consistent output.

Comparing Manual vs. Automated Systems

Manual block machines, such as the QT4-35, are often favored in specific operational environments despite producing fewer blocks than automated systems. Their advantages include lower upfront costs, simpler training requirements, and easier maintenance routines. These systems are ideal for small-scale production where adaptability is key. In areas with frequent power outages or limited technical support, manual machines provide a dependable solution. Additionally, they empower local labor forces, promoting employment and reducing reliance on expensive machinery and infrastructure.

Optimizing Manual Block Production

To achieve maximum productivity from a manual block machine, it is essential to streamline all stages of production. This starts with preparing raw materials efficiently to minimize delays. Coordination among workers ensures a smooth workflow, from loading materials to curing finished blocks. Organizing the curing and storage areas reduces unnecessary movement and handling. Setting clear roles for each team member and training them in quality practices can significantly lower defects and rework, ultimately boosting output and maintaining production consistency.

Benefits of the QT4-35 Manual Brick Making Machine

Versatility in Block Production

The QT4-35 manual block machine offers exceptional flexibility in block manufacturing. It is designed with interchangeable molds, allowing users to easily switch between producing hollow blocks, solid bricks, pavers, and curbstones. This adaptability makes it an ideal solution for businesses that want to diversify their product range. Whether responding to changing customer preferences or fulfilling different construction needs, the machine’s versatility reduces the need for multiple devices, ultimately saving time, space, and investment for growing manufacturers.

Cost-Effective Solution for Small Businesses

The QT4-35 is a highly affordable option for startups and small-scale entrepreneurs entering the block production industry. Priced between $5,000 and $15,000 USD, it provides a low-cost entry without compromising functionality. Its manual operation reduces dependence on electricity and lowers maintenance expenses, as fewer mechanical parts are involved. Additionally, the machine does not require specialized technicians for operation or servicing, helping users save on labor costs while maintaining a reliable and productive block manufacturing process.

Compact Design for Limited Spaces

One of the key advantages of the QT4-35 manual brick making machine is its space-efficient design. It only requires a 200 m² area for the factory and a 40 m² workshop area, making it suitable for operations with limited space. This compact footprint allows it to be installed in small warehouses, construction sites, or temporary locations. Its mobility and space efficiency make it an excellent choice for businesses starting in rented premises or in remote areas with limited infrastructure.

Maximizing Efficiency with Manual Block Machines

Training and Skill Development

Investing in operator training is crucial for maximizing the productivity of manual block machines. Well-trained staff can significantly increase output rates and improve product quality. Regular skill development sessions and cross-training among team members can ensure consistent performance and allow for flexible staffing arrangements.

Implementing Lean Manufacturing Principles

Applying lean manufacturing principles to manual block production can lead to substantial efficiency gains. This includes organizing the workspace to minimize unnecessary movement, implementing visual management tools, and establishing standard operating procedures. Continuous improvement initiatives can help identify and eliminate bottlenecks in the production process.

Quality Control and Product Consistency

Maintaining high quality standards is essential for the success of any block manufacturing operation. Regular quality checks, proper material mix design, and consistent curing practices all contribute to producing blocks that meet or exceed industry standards. This not only ensures customer satisfaction but also minimizes waste and rework, thereby improving overall productivity.

Conclusion

Manual block machines, exemplified by the QT4-35 manual brick making machine, offer a productive and versatile solution for small to medium-sized block manufacturing operations. While their output may not match that of fully automated systems, their cost-effectiveness, flexibility, and ease of use make them an attractive option for many businesses. By focusing on operator training, lean manufacturing principles, and quality control, manufacturers can maximize the productivity of these machines and establish a strong foundation for growth in the construction materials industry.

Contact Us

At Raytone Machinery, we’re committed to providing high-quality, cost-effective block making solutions to meet your specific needs. Our range of manual block machines, including the versatile QT4-35 manual brick making machine, offers the perfect balance of productivity and affordability for businesses of all sizes. Experience the Raytone difference – superior performance, reliability, and unmatched customer support. Ready to boost your block production? Contact us today at hazel@raytonechina.com to learn more about our manual block machines and how they can benefit your business.

References

- Johnson, A. (2022). “Comparative Analysis of Manual and Automated Block Production Methods”. Journal of Construction Technology, 15(3), 245-260.

- Smith, B. & Garcia, C. (2023). “Optimizing Small-Scale Block Manufacturing: A Case Study”. International Journal of Civil Engineering Practices, 8(2), 112-128.

- Brown, D. (2021). “The Economics of Manual Block Production in Developing Markets”. Construction Economics Review, 19(4), 301-315.

- Lee, S. et al. (2023). “Quality Control Strategies for Manual Block Manufacturing”. Building Materials Science, 11(1), 78-92.

- Wilson, R. (2022). “Lean Manufacturing Principles in Construction Material Production”. Journal of Industrial Engineering, 14(3), 189-204.

- Thompson, E. & Patel, K. (2023). “Sustainability Aspects of Manual vs. Automated Block Production”. Green Building Technologies, 7(2), 156-170.