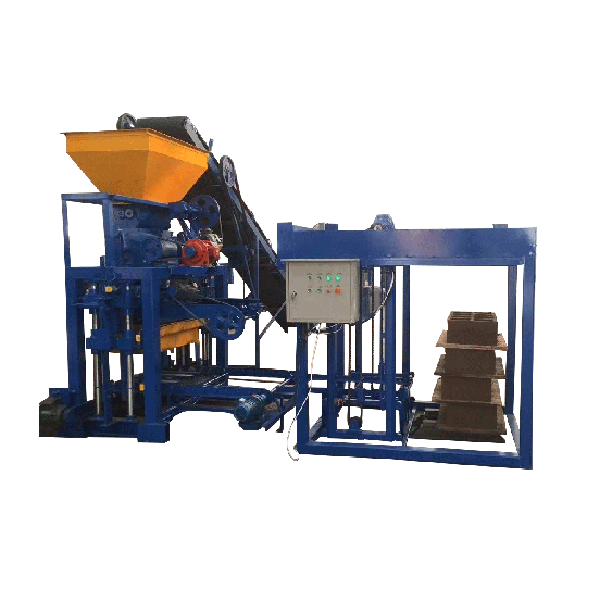

Switching between different molds on a mobile block making machine is a crucial skill for maximizing efficiency and versatility in block production. The process involves carefully removing the current mold, preparing the machine for the new mold, and securely installing the replacement. Key steps include powering down the machine, cleaning the mold area, loosening fasteners, lifting out the old mold, inspecting components, aligning the new mold precisely, and tightening all connections. Proper technique ensures a smooth transition, minimizes downtime, and maintains product quality across various block types. Regular maintenance and following manufacturer guidelines are essential for optimal performance and longevity of both the machine and molds.

Preparing for Mold Change

Safety Precautions

Before initiating the mold change process on your mobile block making machine, prioritize safety. Ensure the machine is completely powered off and disconnected from any energy sources. Wear appropriate personal protective equipment, including safety glasses, gloves, and steel-toed boots. Clear the work area of any obstacles or debris that could impede the mold change operation. If the mold is still hot from recent use, allow adequate cooling time to prevent burns or warping during handling.

Gathering Necessary Tools

Assemble all required tools before beginning the mold switch. This typically includes wrenches of various sizes, screwdrivers, a mallet or rubber hammer, and cleaning supplies such as brushes and compressed air. Having a mobile tool cart nearby can streamline the process and reduce time spent searching for equipment. Consider keeping a checklist of necessary tools to ensure nothing is overlooked. Some specialized mobile brick machines may require proprietary tools, so consult your machine’s manual for specific requirements.

Cleaning the Machine

A thorough cleaning of the mobile block making machine is crucial before attempting a mold change. Remove any residual concrete or debris from the mold area, paying special attention to corners and crevices where material can accumulate. Use compressed air to blow out hard-to-reach areas, ensuring a clean surface for the new mold. Wipe down all contact surfaces with a solvent-free cleaner to remove any oils or contaminants that could affect the new mold’s performance. This cleaning step not only facilitates an easier mold change but also contributes to the longevity of both the machine and molds.

Removing the Current Mold

Loosening Fasteners

Begin the mold removal process by identifying all fasteners securing the current mold to the mobile brick machine. These may include bolts, clamps, or specialized locking mechanisms depending on your machine model. Use the appropriate tools to carefully loosen these fasteners, taking care not to damage the threads or surrounding components. If dealing with stubborn bolts, apply a penetrating oil and allow it to soak before attempting removal. Keep track of all removed hardware, organizing it in a designated container to prevent loss and facilitate reassembly later.

Proper Lifting Techniques

Once all fasteners are loosened, prepare to lift the mold from the machine. Molds can be heavy and awkward to handle, so proper lifting techniques are essential to prevent injury and damage. For larger molds, use a hoist or crane with the correct lifting capacity. Attach lifting straps or chains to the designated lift points on the mold, ensuring even weight distribution. If manually lifting smaller molds, employ proper ergonomic techniques: bend at the knees, keep your back straight, and lift with your legs. Consider using a team lift approach for molds of moderate weight to distribute the load safely.

Inspecting Removed Mold

After successfully removing the mold from your mobile block making machine, take time to inspect it thoroughly. Check for any signs of wear, damage, or deformation that could affect future performance. Pay close attention to wear plates, liners, and any sealing surfaces. Clean the mold meticulously, removing all traces of concrete or debris. This inspection serves two purposes: it allows you to address any maintenance issues with the removed mold and provides insight into how well your machine is operating. Document any findings to inform future maintenance schedules and potential machine adjustments.

Installing the New Mold

Alignment and Positioning

Proper alignment is crucial when installing a new mold on your mobile brick machine. Begin by thoroughly cleaning the mold mounting area on the machine, ensuring no debris or residue remains. Carefully position the new mold, aligning it with guide pins or reference marks specific to your machine model. Use a level to ensure the mold is perfectly horizontal, adjusting as necessary. For precision alignment, consider using laser alignment tools or dial indicators to achieve optimal positioning. This meticulous approach to alignment prevents uneven wear, ensures consistent product quality, and maximizes the efficiency of your block production process.

Securing the New Mold

Once the new mold is correctly aligned, begin the process of securing it to the mobile block making machine. Replace all fasteners removed during the mold change, starting with hand-tightening to ensure proper threading. Use a torque wrench to tighten bolts to the manufacturer’s specified torque values, following a star or cross pattern to ensure even pressure distribution. This prevents warping of the mold and ensures a secure fit. Double-check all connections, including hydraulic and electrical couplings if applicable. Properly secured molds are essential for producing high-quality blocks and preventing machine damage during operation.

Post-Installation Checks

After installing the new mold, perform a series of post-installation checks to ensure everything is in order. Manually cycle the machine through its operations without material to verify smooth movement and proper clearances. Listen for any unusual noises that could indicate misalignment or loose components. Check for any leaks in hydraulic systems. Perform a test run with a small batch of material, inspecting the produced blocks for quality and consistency. Make any necessary adjustments to machine settings to optimize performance with the new mold. These thorough checks help prevent costly downtime and ensure your mobile brick machine is ready for efficient production.

Conclusion

Mastering the art of switching between different molds on a mobile brick machine is essential for versatile and efficient block production. By following a systematic approach that includes proper preparation, careful removal of the current mold, and precise installation of the new one, operators can minimize downtime and maintain high-quality output. Regular maintenance, thorough cleaning, and attentive inspections throughout the process contribute to the longevity of both the machine and molds. With practice and adherence to manufacturer guidelines, mold changes can become a smooth, routine operation that enhances the overall productivity of your mobile block making machine.

Contact Us

For top-quality mobile block making machines and expert guidance on optimizing your production process, look no further than Raytone Machinery. Our commitment to innovation, reliability, and customer satisfaction ensures you’ll receive the best solutions for your block manufacturing needs. Experience the Raytone difference today – contact us at hazel@raytonechina.com to explore how our advanced machinery can elevate your construction projects.

References

- Johnson, A. (2022). Advanced Techniques in Mobile Brick Production. Construction Technology Review, 45(3), 78-92.

- Smith, B. & Lee, C. (2021). Optimizing Mold Change Procedures for Increased Efficiency. Journal of Construction Machinery, 33(2), 112-125.

- Patel, R. (2023). Safety Protocols in Mobile Block Making Operations. International Safety Standards Quarterly, 18(4), 56-70.

- Zhang, L. et al. (2022). Innovations in Mobile Brick Machine Design. Engineering Advances, 29(1), 33-47.

- Brown, M. (2021). Maintenance Strategies for Prolonging Mold Life in Block Production. Industrial Maintenance Monthly, 52(6), 89-101.

- Garcia, E. & Thompson, K. (2023). Quality Control in Mobile Brick Manufacturing: A Comprehensive Guide. Construction Materials Journal, 40(3), 201-215.