Selecting the right brick making machine for your project is crucial for success in the construction industry. When choosing a brick machine, two primary factors come into play: your budget and desired output. A higher budget typically allows for more advanced, automated machines with greater production capacity, while a lower budget might necessitate a more manual or semi-automatic option. Consider your daily production needs carefully – do you require thousands of bricks per day, or is a smaller output sufficient? Additionally, factor in long-term costs such as maintenance, energy consumption, and potential upgrades. By balancing these aspects with the initial investment, you can find a brick machine that not only fits your current budget but also meets your production goals efficiently, ensuring a wise investment for your business’s future growth.

Understanding Brick Machine Types and Their Capabilities

Manual Brick Machines: Budget-Friendly Options for Small-Scale Production

Manual brick machines are an excellent starting point for those with limited budgets or small-scale production needs. These machines rely on human power for most operations, from mixing materials to molding and ejecting bricks. While they require more physical labor, manual machines offer several advantages:

– Low initial investment cost

– Minimal maintenance requirements

– Flexibility in production location

– Ideal for small businesses or DIY projects

However, it’s important to note that manual machines have limitations in terms of output. They typically produce between 500 to 1,500 bricks per day, depending on the operator’s efficiency and the number of molds available. This output range makes them suitable for local construction projects or small-scale brick manufacturing operations.

Semi-Automatic Brick Machines: Balancing Cost and Productivity

Semi-automatic brick making machines offer a middle ground between manual and fully automatic options. These machines automate certain aspects of the brick-making process, such as material feeding or brick ejection, while still requiring some manual intervention. Key features of semi-automatic machines include:

– Higher production capacity compared to manual machines

– Reduced labor requirements

– Improved consistency in brick quality

– Moderate initial investment

Semi-automatic brick machines can produce anywhere from 2,000 to 8,000 bricks per day, making them suitable for medium-sized construction projects or brick manufacturing businesses. They offer a good balance between investment and output, allowing businesses to scale up production without committing to the higher costs of fully automatic systems.

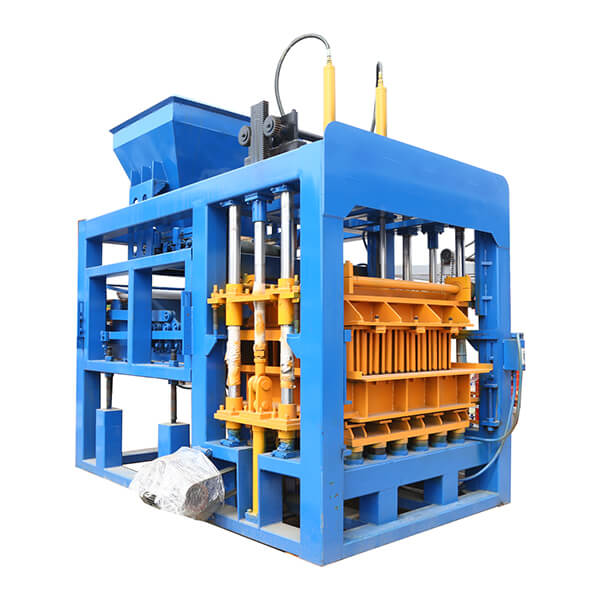

Fully Automatic Brick Machines: High-Output Solutions for Large-Scale Production

For those with larger budgets and high production demands, fully automatic brick machines are the go-to choice. These sophisticated systems automate the entire brick-making process, from material mixing to brick curing. Key advantages of fully automatic machines include:

– Highest production capacity, ranging from 10,000 to over 100,000 bricks per day

– Consistent quality and uniformity in brick production

– Minimal labor requirements

– Enhanced efficiency and reduced waste

While fully automatic brick machines require a significant initial investment, they offer the lowest cost per brick in large-scale production. These machines are ideal for industrial-scale brick manufacturing, large construction companies, or businesses looking to expand their production capabilities significantly.

Factors to Consider When Budgeting for a Brick Machine

Initial Investment vs. Long-Term Operational Costs

When budgeting for a brick making machine, it’s crucial to look beyond the initial purchase price. While a lower upfront cost might seem attractive, it’s essential to consider the long-term operational expenses. Factors to evaluate include:

– Energy consumption: Automatic machines may have higher energy costs but offer greater efficiency.

– Maintenance requirements: More complex machines might need specialized maintenance, affecting long-term costs.

– Labor costs: Manual machines require more labor, impacting ongoing operational expenses.

– Production efficiency: Higher output machines may have a higher initial cost but lower per-brick production costs.

By carefully analyzing these factors, you can determine the true cost of ownership over the machine’s lifespan, helping you make a more informed decision that aligns with your budget and production goals.

Financing Options and Return on Investment

For many businesses, especially those looking at higher-end brick making machines, financing can be a crucial consideration. Explore various financing options such as:

– Equipment leasing

– Bank loans

– Vendor financing programs

– Government grants or subsidies for small businesses or sustainable manufacturing

When considering financing, calculate the potential return on investment (ROI) based on your projected production and sales. A higher-capacity machine might offer a faster ROI despite its higher initial cost, thanks to increased production efficiency and output.

Scalability and Future Growth Considerations

As you budget for a brick machine, think about your business’s future growth potential. Consider:

– Modular systems that allow for easy upgrades or expansion

– Machines with adjustable output capacities

The potential for adding automation features to semi-automatic machines in the future

Investing in a machine that can grow with your business might cost more initially but can save significant expenses in the long run by avoiding the need for complete system replacements as your production needs increase.

Matching Brick Machine Output to Your Production Needs

Analyzing Market Demand and Production Targets

Before selecting a brick machine based on output, it’s crucial to conduct a thorough analysis of your market demand and set realistic production targets. Consider the following:

– Local construction activity and trends

– Seasonal fluctuations in demand

– Potential for expanding into new markets

– Competitive landscape and market share goals

By understanding your market thoroughly, you can better estimate the required daily, monthly, and annual brick production. This analysis will guide you in choosing a machine with the appropriate output capacity, ensuring you can meet demand without overinvesting in unnecessary production capacity.

Calculating Optimal Production Capacity

Determining the optimal production capacity for your brick making machine involves balancing several factors:

– Peak demand periods

– Storage capacity for finished bricks

– Lead times for orders

– Maintenance downtime

A good rule of thumb is to choose a machine with a capacity that exceeds your average daily demand by 20-30%. This buffer allows for unexpected increases in demand, machine downtime, and potential future growth. However, be cautious not to oversize your production capacity significantly, as this can lead to inefficiencies and increased costs per brick.

Considering Product Variety and Customization Needs

When evaluating brick machine output, consider not just quantity but also the variety of products you need to produce. Modern construction often requires different types of bricks and blocks, such as:

– Standard solid bricks

– Hollow blocks

– Interlocking bricks

– Paving stones

Choose a machine that offers flexibility in mold changes and can produce the range of products your market demands. Some advanced machines allow for quick mold changes, enabling you to switch between different brick types efficiently. This versatility can be a significant advantage, allowing you to respond quickly to market trends and customer requests without sacrificing overall output.

Conclusion

Choosing the right brick machine based on your budget and output needs is a critical decision that can significantly impact your business’s success. By carefully considering the types of machines available, thoroughly analyzing your budget constraints, and accurately assessing your production requirements, you can make an informed choice that balances cost-effectiveness with productivity. Remember to look beyond the initial investment, considering long-term operational costs, scalability, and the ability to meet diverse product demands. With the right brick machine, you’ll be well-positioned to meet market needs efficiently and grow your business sustainably in the competitive construction industry.

Contact Us

At Raytone Machinery, we understand the complexities of choosing the perfect brick making machine for your business. Our extensive range of high-quality concrete block machines, from manual to fully automatic systems, is designed to meet diverse production needs and budgets. With our commitment to performance, reliability, and cost-effectiveness, we ensure excellent value for every customer. Let us help you find the ideal brick machine solution that aligns with your production goals and budget. For personalized advice and more information about our products, please contact us at hazel@raytonechina.com. Take the first step towards optimizing your brick production today!

References

- Smith, J. (2022). “The Economics of Brick Manufacturing: A Comprehensive Guide”

- Johnson, L. et al. (2021). “Advancements in Automated Brick Production Technologies”

- Brown, R. (2023). “Sustainable Practices in Modern Brick Making”

- Construction Industry Association. (2022). “Annual Report on Global Brick Demand Trends”

- Zhang, Y. (2021). “Comparative Analysis of Manual, Semi-Automatic, and Fully Automatic Brick Machines”

- Davis, M. (2023). “Optimizing Brick Production: Balancing Efficiency and Quality”