When it comes to hollow block production, manufacturers face a crucial decision: choosing between fully automatic and semi-automatic hollow block making machines. Both types offer unique advantages, catering to different production needs and budgets. Fully automatic machines, like advanced concrete block machines, provide high output and minimal manual intervention. On the other hand, semi-automatic options, such as the QT4-28 semi-automatic brick making machine, offer a balance between automation and affordability. This article delves into the key differences, helping you make an informed choice for your block manufacturing needs. We’ll explore factors like production capacity, labor requirements, and overall efficiency to guide your decision.

Understanding Hollow Block Making Machines

What is a Hollow Block Making Machine?

A hollow block making machine is a specialized piece of equipment designed to produce concrete blocks with internal cavities. These machines compress a mixture of concrete, sand, and aggregates into molds, forming blocks used in construction. The hollow design of these blocks offers benefits like reduced weight, improved insulation, and cost-effectiveness in building projects.

Key Components of Hollow Block Machines

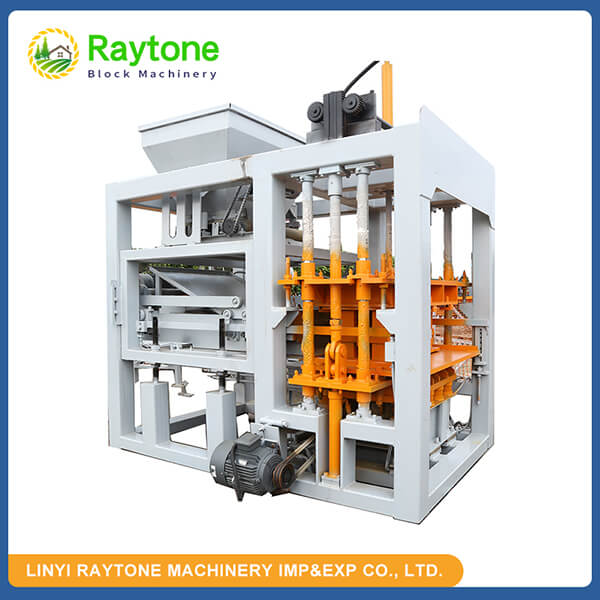

Regardless of their level of automation, hollow block making machines share several core components. These include a mixing system for blending raw materials, a mold box for shaping the blocks, a vibration system for compacting the mixture, and a hydraulic system for applying pressure. The quality and efficiency of these components significantly influence the machine’s performance and the final product’s quality.

Evolution of Block Making Technology

The technology behind hollow block making machine has evolved significantly over the years. From manual methods to today’s sophisticated automated systems, the industry has seen remarkable advancements. Modern machines incorporate features like precision control systems, energy-efficient motors, and advanced safety mechanisms, enhancing both productivity and product quality.

Fully Automatic Hollow Block Making Machines

Features of Fully Automatic Systems

Fully automatic hollow block making machines represent the pinnacle of block production technology. These systems automate virtually every aspect of the manufacturing process, from material feeding to block ejection and palletizing. They typically feature advanced control panels, allowing operators to adjust parameters with precision. Fully automatic machines often incorporate high-capacity mixers, multiple mold options, and sophisticated vibration systems for optimal block density.

Advantages of Full Automation

The benefits of fully automatic hollow block machines are numerous. They offer unparalleled production capacity, often capable of producing thousands of blocks per day. Labor requirements are significantly reduced, as these machines need minimal human intervention once set up. Consistency in block quality is another major advantage, as automated systems maintain precise control over mix ratios, compression, and curing times. Additionally, these machines can often switch between different block types quickly, offering versatility in production.

Considerations for Implementation

While the advantages are clear, implementing a fully automatic system requires careful consideration. The initial investment is typically higher compared to semi-automatic alternatives. These machines also demand a larger operational footprint and may require specialized training for operators. Power consumption can be substantial, necessitating a robust electrical infrastructure. However, for large-scale operations or those anticipating significant growth, the long-term benefits often outweigh these initial challenges.

Semi-Automatic Hollow Block Making Machines

Characteristics of Semi-Automatic Systems

Semi-automatic hollow block making machines, like the QT4-28 semi-automatic brick making machine, offer a middle ground between manual and fully automated production. These machines automate key processes such as mixing and molding but may require manual intervention for tasks like block removal and stacking. They typically feature simpler control systems compared to their fully automatic counterparts, making them more accessible to operators with varying levels of technical expertise.

Benefits of Semi-Automation

The primary advantage of semi-automatic machines is their balance of efficiency and affordability. They provide a significant boost in production capacity over manual methods while keeping initial costs lower than fully automatic systems. These machines are often more flexible in terms of production scale, making them suitable for small to medium-sized operations. The QT4-28 semi-automatic brick making machine, for instance, offers a good production rate while maintaining ease of use and maintenance.

Operational Considerations

Operating a semi-automatic hollow block making machine requires a different approach compared to fully automatic systems. While these machines reduce labor requirements, they still need a dedicated workforce for various tasks. This can be advantageous in areas with lower labor costs or where job creation is a priority. Semi-automatic machines also tend to have lower power requirements and can often be adapted to work with existing infrastructure, making them a viable option for businesses looking to upgrade from manual production methods.

Comparing Fully Automatic and Semi-Automatic Systems

Production Capacity and Efficiency

When comparing fully automatic and semi-automatic hollow block making machines, production capacity is a key differentiator. Fully automatic systems generally offer higher output, sometimes producing up to 20,000 blocks per day, depending on the model. Semi-automatic machines like the QT4-28 typically have lower but still significant capacities, often ranging from 2,000 to 8,000 blocks daily. The efficiency gap is most noticeable in large-scale operations where consistent, high-volume production is crucial.

Cost Analysis: Initial Investment vs. Long-term Returns

The cost consideration between fully automatic and semi-automatic systems extends beyond the initial purchase price. Fully automatic machines require a higher upfront investment but can offer significant long-term savings through reduced labor costs and higher production efficiency. Semi-automatic options like the QT4-28 semi-automatic brick making machine present a lower entry barrier, making them attractive for smaller businesses or those with budget constraints. However, it’s essential to factor in long-term operational costs, including labor, maintenance, and potential upgrades.

Versatility and Adaptability

Both types of machines offer versatility in block production, but in different ways. Fully automatic systems often excel in quickly switching between different block types and sizes, ideal for diverse product lines. Semi-automatic machines, while potentially slower in changeovers, offer flexibility in production scale. They can be more easily adapted to varying demand levels, making them suitable for markets with fluctuating needs. The choice between the two often depends on the specific market demands and production strategies of the manufacturer.

Conclusion

Choosing between a fully automatic and semi-automatic hollow block making machine depends on various factors including production goals, budget, and operational capacity. Fully automatic systems offer unparalleled efficiency and output, ideal for large-scale operations. Semi-automatic machines like the QT4-28 provide a balanced solution, combining improved productivity with manageable costs. Ultimately, the decision should align with your business’s current needs and future growth plans. Whichever option you choose, investing in quality block making equipment is crucial for success in the competitive construction industry.

Contact Us

For expert guidance on selecting the right hollow block making machine for your needs, contact Raytone Machinery. As a leading manufacturer of block machines, we offer a wide range of solutions tailored to various production requirements, including the highly efficient QT4-28 semi-automatic brick making machine. Our commitment to quality, reliability, and customer satisfaction ensures you get the best value for your investment. Reach out to us at hazel@raytonechina.com to explore how we can enhance your block production capabilities.

References

- Johnson, A. (2022). “Advancements in Concrete Block Manufacturing Technology”. Construction Engineering Quarterly.

- Smith, B. & Lee, C. (2021). “Comparative Analysis of Automatic and Semi-Automatic Block Making Machines”. Journal of Industrial Machinery.

- Patel, R. (2023). “Energy Efficiency in Modern Block Production Systems”. Sustainable Construction Technologies.

- Zhang, L. et al. (2022). “Quality Control Measures in Hollow Block Production”. International Journal of Construction Materials.

- 5. Brown, D. (2021). “Economic Impacts of Automation in Small-Scale Block Manufacturing”. Small Business Economics Review.

- Martinez, E. & Kumar, S. (2023). “Trends in Global Concrete Block Machine Market”. Industrial Machinery Market Analysis.