In the evolving world of block making, manufacturers are constantly seeking equipment that delivers efficiency, durability, and sustainability. Among the many components that determine the success of a production line, brick pallets play a pivotal role. Traditional materials such as wood and plastic have long been used, but with the rise of advanced manufacturing technologies, GMT (Glass Mat Reinforced Thermoplastic) brick pallets have emerged as the superior alternative. These innovative pallets offer unmatched strength, longevity, and environmental benefits, making them an essential upgrade for modern block making machines.

1. The Structural Difference: What Makes GMT Unique

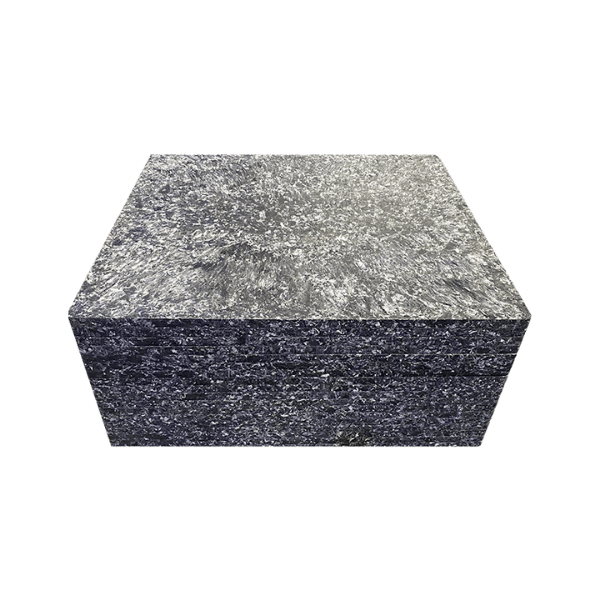

At the core of GMT’s superiority lies its advanced material composition. Unlike wooden or plastic pallets, GMT brick pallets are made from glass fiber mats combined with thermoplastic resin, compressed under extreme heat and pressure—often exceeding 3000 tons. This manufacturing process produces a dense, uniform composite (around 1200 kg/m³ in density) that’s both lightweight and exceptionally durable.

Wooden pallets, by contrast, are prone to warping, cracking, and absorbing moisture, leading to frequent replacements. Plastic pallets, though water-resistant, tend to deform under high temperatures or heavy loads. GMT pallets eliminate these issues entirely, offering stable performance even in high-pressure brick machine environments.

2. Performance Advantages in Block Machine Applications

In block production lines, precision and consistency are critical. GMT pallets maintain their shape and strength during vibration and compaction, ensuring that concrete blocks are molded accurately every time. Their waterproof and corrosion-resistant properties prevent swelling or damage, even when continuously exposed to wet cement.

For automatic brick making machines such as the QT4-15, QT6-15, and QT10-15, dimensional stability is key to smooth operation. GMT pallets deliver this stability, minimizing machine wear and reducing downtime. This reliability allows operators to achieve higher output rates and better block quality without constant adjustments or replacements—an issue often encountered with wood and plastic alternatives.

3. Durability and Lifespan Comparison

One of the strongest arguments in favor of GMT pallets is their longevity. A typical GMT brick pallet lasts between 8 to 10 years, outperforming both wooden and plastic types by a wide margin:

-

Wooden pallets: 2 years (susceptible to rot, termites, and cracking)

-

Plastic pallets: 6 years (prone to deformation and surface wear)

-

Bamboo pallets: 4 years (moderate strength, but less water resistance)

-

GMT pallets: 8–10 years (resistant to moisture, impact, and temperature extremes)

This extended lifespan drastically lowers replacement frequency, minimizing maintenance costs and maximizing return on investment—especially for large-scale concrete block production lines.

4. Cost Efficiency Over Time

While wooden pallets appear inexpensive at first, their short life cycle results in frequent replacements and increased long-term expenses. Plastic pallets, on the other hand, are often more expensive upfront and less environmentally sustainable. GMT pallets strike the perfect balance between affordability and endurance.

Their cost per use is significantly lower thanks to reduced maintenance needs and minimal downtime. Over a 10-year period, a factory using GMT pallets can save up to 30% compared to operations using PVC or wooden alternatives. This cost advantage becomes even more substantial when factoring in labor, storage, and waste management savings.

5. Environmental Sustainability and Compliance

Sustainability is now a core business priority for manufacturers worldwide, and GMT brick pallets align perfectly with these goals. Produced using recycled glass fibers and thermoplastic materials, they help reduce industrial waste and the demand for new raw resources. Moreover, at the end of their service life, GMT pallets are fully recyclable—contributing to a circular production model.

In contrast, wooden pallets drive deforestation, while plastic pallets rely on petroleum-based raw materials and are harder to recycle. By adopting GMT technology, manufacturers not only reduce their environmental footprint but also strengthen their brand’s eco-friendly image—an increasingly important factor for global buyers.

6. Lightweight and Easy Handling

GMT pallets combine strength with low weight, making them easy to handle and transport. With a density of approximately 1200 kg/m³, they are significantly lighter than steel or concrete alternatives yet strong enough to support heavy block loads of up to 2500 kg.

This lightweight feature improves workplace safety and efficiency—reducing labor fatigue and enabling smoother transitions between molding, curing, and stacking processes. The result is an optimized block production line that operates faster and with fewer manual adjustments.

7. Adaptability to Modern Brick Machine Models

GMT brick pallets are fully compatible with all major block making machine models, including fully automatic, semi-automatic, and mobile units. Their precision manufacturing ensures perfect alignment and minimal vibration loss, making them ideal for machines such as:

-

QT4-24 semi-automatic brick making machine

-

QT6-15 automatic block machine

-

QT10-15 heavy-duty block production line

-

QTM6-25 mobile block machine

Whether producing hollow blocks, paving stones, or interlocking bricks, GMT pallets provide the stable foundation required for consistent high-quality output.

8. Real-World Performance and Customer Feedback

Manufacturers who have switched to Raytone Machinery’s GMT brick pallets report a noticeable improvement in production stability and cost savings. Customers highlight reduced pallet breakage rates, improved block smoothness, and better performance under continuous vibration. Many also emphasize the benefit of reduced downtime—an important factor for maintaining consistent delivery schedules in global construction projects.

9. Why GMT Is the Future of Brick Machine Pallets

As the block making industry embraces automation, sustainability, and precision manufacturing, the need for advanced materials is inevitable. GMT technology addresses every limitation of traditional pallets—delivering the perfect blend of strength, cost-effectiveness, and environmental responsibility.

With longer service life, improved mechanical stability, and global compliance with environmental standards, GMT brick pallets are not just an alternative—they are the future of concrete block production.

10. Partner with Raytone Machinery for Advanced GMT Solutions

Raytone Machinery stands at the forefront of innovation in the brick-making industry. With years of expertise in designing and manufacturing block machines and GMT brick pallets, Raytone provides complete solutions for global clients. The company’s products combine engineering precision with sustainability, ensuring top performance across all production lines.

Advantages of working with Raytone Machinery:

-

Tailored GMT pallet sizes for every block machine model

-

Factory-direct prices and strict quality control

-

24/7 technical support and global after-sales service

-

Custom mold design and production line optimization

Conclusion

GMT brick pallets represent the next generation of block making equipment. By outperforming wooden and plastic options in durability, cost efficiency, and sustainability, they enable manufacturers to produce more efficiently, profitably, and responsibly.

For block factories aiming to stay competitive in a demanding global market, the choice is clear. Switch to GMT—powered by Raytone Machinery—and experience the perfect combination of innovation, longevity, and performance.

📧 Contact us today at hazel@raytonechina.com to learn how customized GMT brick pallets can transform your block machine operations and maximize your production efficiency.