In the highly competitive brick machine industry, manufacturers are constantly searching for durable, cost-effective, and environmentally friendly materials to improve production efficiency. One innovation that has redefined the standards for block machine pallet systems is the GMT brick pallet—a modern solution designed to outperform traditional wooden, bamboo, and PVC pallets in every aspect of block production.

Superior Moisture and Mold Resistance

One of the most critical challenges in concrete block production lines is maintaining pallet quality under constant exposure to wet concrete. Traditional wooden or bamboo pallets absorb water easily, causing deformation, cracking, and mold growth. GMT brick pallets, on the other hand, are completely resistant to moisture and mold.

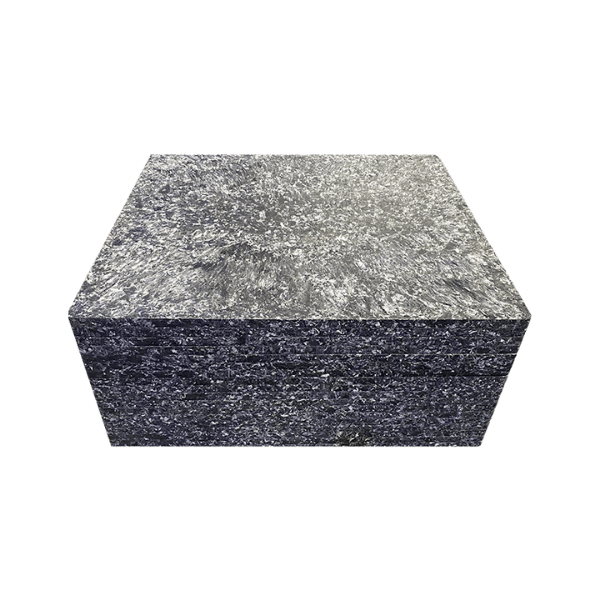

Made from glass fiber mat reinforced thermoplastic (GMT) material, these pallets feature a non-porous surface that prevents water absorption. Whether used in tropical climates or humid factory environments, GMT pallets retain their shape and strength. This resistance ensures a longer lifespan and consistent block quality—essential for automatic and semi-automatic block machine operations.

Engineered for Strength and Stability

GMT (Glass Mat Reinforced Thermoplastic) is a composite material created under high temperature and pressure using advanced 3000-ton compression molding machines. The result is a dense, rigid, and impact-resistant pallet with a density of about 1200 kg/m³.

This structure allows GMT pallets to withstand the repeated vibration and compaction forces of high-performance hydraulic brick-making machines such as QT4-18, QT4-24, and QT6-15 models. Even after years of continuous use, these pallets do not warp or crack, providing unmatched stability in cement brick manufacturing lines.

Comparing GMT with Traditional Pallet Materials

Traditional pallets for brick machines—including wood, bamboo, and PVC—have distinct limitations. Wooden pallets are low-cost but have a very short lifespan, often lasting only 1–2 years. Bamboo pallets perform slightly better, lasting around 3–4 years, but still deteriorate quickly in humid conditions.

PVC pallets are durable but significantly more expensive, making them less suitable for budget-conscious manufacturers. GMT brick pallets bridge this gap perfectly. They offer up to 8–10 years of service life while maintaining excellent cost-to-performance value. Their ability to resist moisture, corrosion, and heat deformation makes them the most cost-effective pallet choice for block production plants worldwide.

Enhanced Durability in Harsh Environments

During the concrete block production process, pallets endure constant vibration, heavy load pressure, and exposure to cement slurry. GMT pallets are designed specifically to handle these demanding conditions. Their reinforced glass fiber structure ensures that they won’t bend or fracture under pressure, even when carrying large paver or hollow blocks.

Moreover, these pallets perform well under extreme temperature fluctuations. Whether in hot, humid regions or areas prone to freezing and thawing, GMT pallets maintain their physical integrity. This environmental adaptability greatly reduces replacement frequency, minimizing downtime and production losses for brick machine manufacturers.

Long-Term Cost-Effectiveness

While the initial investment in GMT pallets is higher than wooden or bamboo alternatives, the long-term benefits are undeniable. Because GMT pallets last up to five times longer, block manufacturers can significantly cut costs on replacements, repairs, and downtime.

Additionally, their lightweight design makes them easier to handle and transport, reducing logistics costs. When compared to PVC pallets, GMT offers a much more balanced price-performance ratio—making them an ideal solution for brick-making plants seeking durability without excessive cost.

Eco-Friendly and Sustainable Production

Sustainability has become a major focus in the global construction machinery industry, and GMT pallets contribute positively to this trend. They are manufactured using recycled composite materials, reducing environmental impact and conserving natural resources. Unlike wooden pallets that contribute to deforestation or PVC pallets that release harmful byproducts, GMT pallets are an eco-friendly alternative aligned with modern green manufacturing principles.

Furthermore, their long lifespan and recyclability mean fewer replacements and less waste over time, reinforcing their reputation as a sustainable choice for eco-conscious block machine operators.

Versatile Application Across Brick Machine Models

GMT brick pallets are suitable for almost all types of brick and block machines—from fully automatic hydraulic systems to manual models. They are compatible with popular equipment such as the QT4-15, QT6-15, QT8-15, and QT10-15 series, used widely for producing hollow blocks, paver blocks, solid bricks, and curbstones.

Their consistent strength and smooth surface ensure accurate block molding and easy demolding, improving production efficiency. Whether used in large-scale automatic production lines or smaller semi-automatic plants, GMT pallets guarantee stable and efficient performance.

Proven Results and Customer Satisfaction

Manufacturers who have switched to GMT pallets report significant improvements in productivity and cost savings. Customers praise their ability to withstand moisture and their resistance to cracking or deformation, even after years of intensive use. Many international brick-making equipment suppliers now recommend GMT pallets as the preferred option for new production setups due to their durability, compatibility, and eco-friendly composition.

The Raytone Advantage

At Linyi Raytone Machinery Manufacturing Co., Ltd., we specialize in providing high-quality brick machines and GMT brick pallets that meet the evolving demands of the global construction market. Our GMT pallets are engineered using cutting-edge technology to deliver exceptional strength, moisture resistance, and long service life. Combined with our automatic block machines and concrete batching systems, they form a complete and efficient solution for concrete block production.

Whether you operate a fully automatic brick production line or a smaller manual block plant, Raytone’s GMT pallets provide the reliability and consistency your business needs to stay competitive.

Conclusion

The future of block machine production lies in durable, eco-friendly, and efficient materials—and GMT brick pallets perfectly embody these qualities. Resistant to moisture and mold, engineered for strength, and designed for long-term savings, GMT pallets represent a smart investment for every brick-making enterprise aiming to enhance performance and reduce costs.

If you’re ready to upgrade your block machine pallets and optimize your production line, contact Raytone Machinery today at hazel@raytonechina.com. Discover how our GMT pallets can transform your manufacturing efficiency and deliver lasting value to your operation.