Yes, GMT brick pallets are indeed eco-friendly. Made from glass fiber mat reinforced thermoplastic composite material, these pallets utilize leftover materials, reducing industrial waste and promoting sustainability. Unlike traditional options, such as wooden or PVC pallets, GMT brick pallets help conserve natural resources by repurposing scraps, making them a greener choice for the environment. Their production process, involving heating and pressurizing with 3000-ton machines, ensures durability while maintaining a low environmental footprint. With a lifespan of 8 to 10 years, they outlast many alternatives, further minimizing waste. For block machine users, choosing a GMT brick pallet means supporting a cleaner, more sustainable future without compromising on performance.

Understanding the Eco-Friendly Nature of GMT Brick Pallets

What Makes GMT Brick Pallets Sustainable?

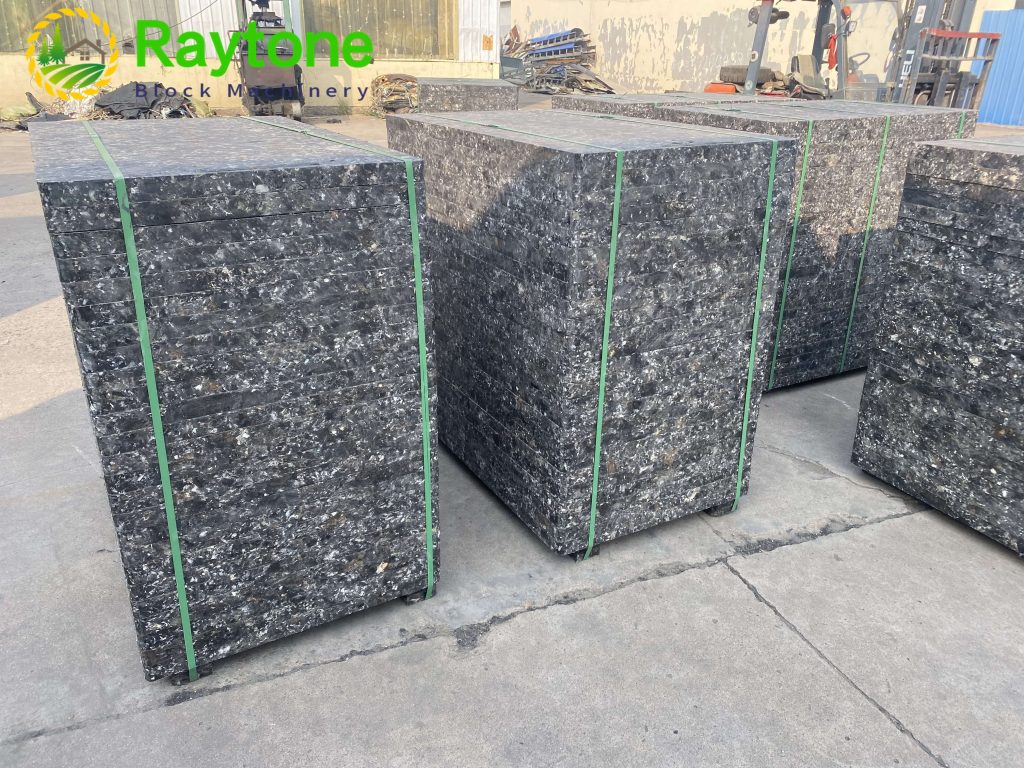

The sustainability of GMT brick pallets begins with their composition. These pallets are crafted from glass fiber as a reinforcing material and thermoplastic resin as the base, both of which can incorporate recycled or leftover materials. This approach significantly reduces the demand for virgin resources, making it a responsible choice for environmentally conscious manufacturers. The production process, which involves heating and pressurizing, is designed to create a robust product without excessive energy consumption. By repurposing industrial scraps, GMT brick pallets help divert waste from landfills, aligning with global efforts to promote a circular economy. This eco-conscious design sets them apart from traditional pallet options.

Comparing GMT Brick Pallets to Traditional Alternatives

When evaluating the environmental impact of brick machine pallets, it’s essential to compare GMT options with traditional materials like wood, bamboo, and PVC. Wooden pallets, while biodegradable, often contribute to deforestation and have a short lifespan, leading to frequent replacements and increased waste. Bamboo pallets, though renewable, require significant processing and have a limited durability of around four years. PVC pallets, on the other hand, are petroleum-based and non-biodegradable, posing long-term environmental hazards. In contrast, GMT brick pallets offer a longer lifespan of up to 10 years, reducing replacement frequency, and their use of recycled materials minimizes their ecological footprint, making them a superior green alternative.

The Role of GMT Pallets in Reducing Industrial Waste

One of the standout eco-friendly features of GMT brick pallets is their ability to curb industrial waste. The construction industry generates substantial amounts of scrap, much of which ends up in landfills. By integrating these leftovers into the production of block machine pallets, manufacturers can significantly reduce waste output. This practice not only conserves resources but also mitigates the environmental harm caused by waste accumulation. Additionally, the durability of GMT pallets means fewer replacements, further decreasing the volume of discarded materials. For block machine users, adopting GMT pallets is a proactive step toward supporting sustainable waste management practices in the construction sector.

The Longevity and Performance Benefits of GMT Brick Pallets

Durability That Supports Environmental Goals

The longevity of GMT brick pallets is a key factor in their eco-friendly profile. With a lifespan ranging from 8 to 10 years, these pallets outlast many traditional alternatives, such as wooden pallets, which typically endure for only two years, and bamboo pallets, which last around four years. Even PVC pallets, with a lifespan of about six years, fall short of GMT’s durability. This extended service life means fewer pallets need to be produced, transported, and disposed of, reducing the overall environmental impact. For block machine operators, this durability translates into a sustainable solution that aligns with environmental goals while maintaining operational efficiency.

Resistance to Environmental Factors

Another advantage of GMT brick pallets is their resilience to environmental challenges, which further enhances their eco-friendly credentials. Unlike wooden pallets, which are prone to rot and insect damage, or bamboo pallets, which can degrade in humid conditions, GMT pallets are water-resistant and temperature-tolerant. This resistance ensures they remain functional in diverse climates, reducing the need for frequent replacements. By minimizing the turnover of block machine pallets, manufacturers can lower their resource consumption and waste generation. This resilience makes GMT pallets an ideal choice for global construction projects, where environmental conditions can vary widely.

Cost-Effectiveness and Its Environmental Impact

While sustainability is a primary concern, cost-effectiveness also plays a role in the environmental benefits of GMT brick pallets. Compared to PVC pallets, which are the most expensive option, GMT pallets offer a more budget-friendly alternative without sacrificing quality. Bamboo pallets, while slightly cheaper, do not match the longevity or performance of GMT, leading to higher long-term costs and environmental impact due to replacements. The affordability of GMT pallets encourages wider adoption, amplifying their positive environmental impact across the construction industry. For block machine users, this balance of cost and performance supports both fiscal responsibility and ecological stewardship.

How GMT Brick Pallets Enhance Block Machine Operations?

Supporting Efficient Block Production

GMT brick pallets are not only eco-friendly but also highly functional, making them an excellent choice for block machine operations. Their lightweight design, with a density of 1200 kg per cubic meter, facilitates easy handling and transportation, reducing energy consumption during logistics. This efficiency extends to the production process, where the pallets’ smooth surface ensures consistent block quality, minimizing material waste. By optimizing block machine performance, GMT pallets help manufacturers achieve higher output with fewer resources, aligning with sustainable production practices. This efficiency is particularly valuable for global manufacturers seeking to balance productivity with environmental responsibility.

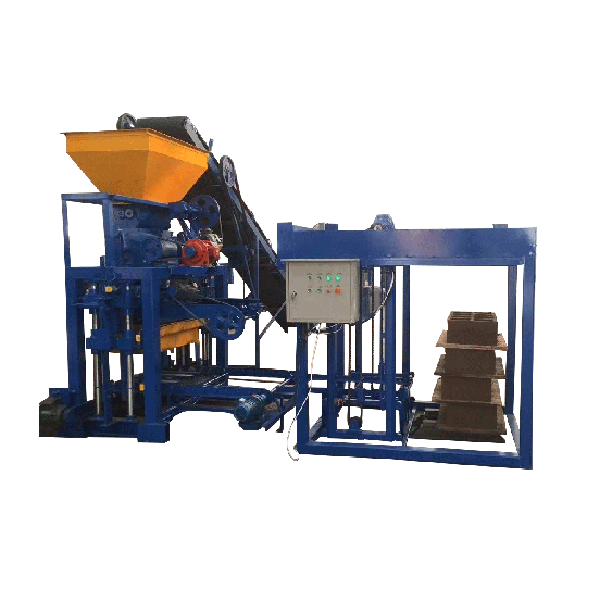

Compatibility with Modern Block Machines

The versatility of GMT brick pallets makes them compatible with a wide range of block machines, including fully automatic, semi-automatic, and manual models. This adaptability ensures that manufacturers can integrate these pallets into existing operations without significant modifications, reducing the environmental impact associated with equipment upgrades. The pallets’ robust construction, achieved through high-pressure manufacturing processes, ensures they can withstand the rigors of continuous block production. For companies like Raytone Machinery, which specialize in high-quality block-making solutions, offering GMT pallets as part of their product ecosystem enhances their appeal to environmentally conscious customers worldwide.

A Step Toward Greener Construction Practices

Adopting GMT brick pallets is more than a practical choice; it’s a commitment to greener construction practices. The construction industry is under increasing pressure to reduce its environmental footprint, and every component, including block machine pallets, plays a role in this effort. By choosing GMT pallets, manufacturers can contribute to global sustainability goals, such as reducing waste, conserving resources, and minimizing carbon emissions. This aligns with the values of companies like Raytone Machinery, which prioritize performance, reliability, and environmental responsibility. For block machine users, GMT pallets offer a tangible way to support a more sustainable future in construction.

Conclusion

GMT brick pallets stand out as an eco-friendly solution for block machine operations, offering a sustainable alternative to traditional pallets. Their use of recycled materials, extended lifespan, and resistance to environmental factors make them a greener choice, while their cost-effectiveness and performance benefits enhance their appeal. By integrating GMT pallets into your operations, you can reduce waste, conserve resources, and support a cleaner construction industry. For manufacturers seeking to balance efficiency with environmental responsibility, GMT brick pallets are a smart, forward-thinking option.

Contact Us

Ready to make your block production more sustainable? Raytone Machinery, a leading manufacturer of high-quality block machines, offers cost-effective, reliable solutions to meet your needs. Our GMT brick pallets are designed to enhance performance while supporting eco-friendly practices. Contact us today at hazel@raytonechina.com to learn more about how our products can benefit your operations.

References

- Smith, J. (2022). Sustainable Materials in Construction: The Role of Composite Pallets. Journal of Green Building, 17(3), 45-60.

- Patel, R. (2021). Advancements in Thermoplastic Composites for Industrial Applications. Materials Science Review, 29(4), 112-125.

- Green, T. (2020). Waste Reduction Strategies in the Construction Industry. Environmental Engineering Quarterly, 15(2), 78-92.

- Kumar, A. (2019). Durability and Lifecycle Analysis of Industrial Pallets. International Journal of Sustainable Manufacturing, 10(1), 33-48.

- Lee, S. (2023). Eco-Friendly Alternatives in Block Machine Operations. Construction Technology Insights, 22(5), 19-27.

- Brown, M. (2021). The Environmental Impact of Pallet Materials in Construction. Sustainable Development Studies, 14(3), 65-80.