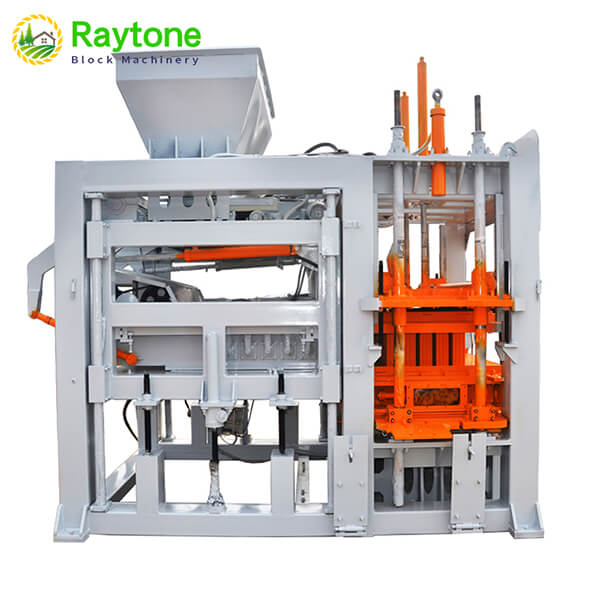

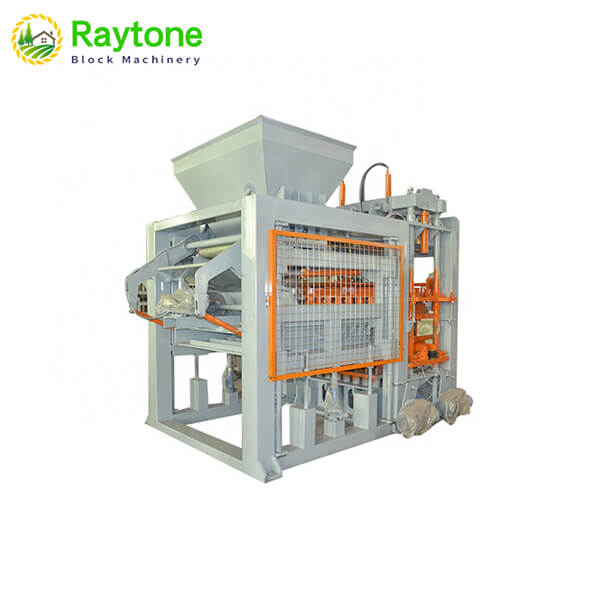

The QT12-15 automatic block machine stands as a pinnacle of customizable block manufacturing technology. This versatile machine offers extensive customization options to meet diverse production requirements across different markets and applications. From adjustable mold configurations to specialized production parameters, the QT12-15 provides remarkable flexibility while maintaining consistent quality output. The machine’s adaptable nature makes it an ideal choice for manufacturers seeking tailored solutions for their specific block production needs.

Comprehensive Customization Options

Mold Customization System

The QT12-15 automatic block machine features an advanced mold customization system that sets it apart in the industry. The machine’s hydraulic transmission system enables seamless mold changes, accommodating various product specifications. This versatility allows manufacturers to produce hollow blocks, solid bricks, color paver bricks, and curbstones using the same machine. The robust construction ensures optimal compaction through its two or four electric motors vibration system, consistently delivering high-quality output regardless of the chosen mold configuration. The machine’s adaptable nature supports production capacities of up to 23,040 eight-inch blocks or 124,800 solid bricks per eight-hour shift, demonstrating its exceptional efficiency across different product types.

Production Line Integration

The QT12-15 automatic block machine excels in its ability to integrate with various production line components. The system seamlessly combines with essential equipment such as cement silos, PLD1200 concrete batching machines, and 750-liter concrete mixers. This integration extends to wet block stacking machines and automatic brick pallet feeders, creating a fully customizable production environment. The flexibility in setup allows manufacturers to optimize their factory layout within areas ranging from 2,500 to 6,500 square meters, requiring only 4-5 workers for operation. This efficient space utilization and minimal workforce requirement make it an economical choice for businesses of various scales.

Technical Parameter Adjustments

The machine offers extensive technical parameter customization options to ensure optimal performance across different production scenarios. The QT12-15 automatic block machine accommodates brick pallets sized 1300x900x35mm, providing a stable foundation for various product dimensions. The hydraulic operation system can be fine-tuned to achieve precise compression rates and vibration frequencies, ensuring consistent product quality. These adjustable parameters, combined with the machine’s affordable price range of 51,400-91,200 USD, make it a cost-effective solution for producing high-quality construction materials.

Performance Enhancement Features

Advanced Hydraulic System

The QT12-15 automatic block machine incorporates a sophisticated hydraulic transmission system that forms the backbone of its customizable operations. This system delivers precise control over compression force and timing, ensuring optimal material density across different product specifications. The hydraulic components are engineered for durability and consistent performance, allowing manufacturers to maintain high production standards even during extended operating periods. The system’s responsive nature enables quick adjustments to accommodate varying material compositions and production requirements, making it ideal for facilities that produce multiple product types.

Vibration Technology Integration

The automatic brick making machine‘s customizable vibration system represents a significant advancement in block-making technology. The QT12-15 automatic block machine employs either two or four electric motors for vibration, providing adjustable frequency and amplitude settings to achieve optimal material consolidation. This sophisticated vibration control system ensures uniform density distribution throughout the products, regardless of their size or configuration. The ability to fine-tune vibration parameters allows manufacturers to optimize product quality while maintaining high production efficiency, making it particularly valuable for facilities producing premium construction materials.

Material Handling Optimization

The QT12-15 automatic block machine features customizable material handling solutions that enhance production efficiency. The integrated PLD1200 concrete batching system allows precise control over material proportions, while the 750-liter concrete mixer ensures thorough blending for consistent product quality. The automated pallet handling system can be adjusted to accommodate different product sizes and production rates, streamlining the manufacturing process. These customizable material handling features, combined with the machine’s robust construction, enable manufacturers to maintain high production standards while minimizing material waste and operating costs.

Quality Assurance Systems

Precision Control Mechanisms

The QT12-15 automatic block machine incorporates advanced precision control mechanisms that ensure consistent product quality. The machine’s computerized control system allows operators to customize production parameters with exceptional accuracy, monitoring key variables such as compression force, vibration intensity, and cycle timing. This level of control ensures that each product meets exact specifications, regardless of the chosen mold configuration or production rate. The system’s ability to maintain precise control over these parameters contributes significantly to the machine’s reputation for producing high-quality construction materials.

Quality Monitoring Integration

The automatic brick making machine‘s quality monitoring capabilities can be customized to meet specific production requirements. The QT12-15 automatic block machine includes sensors and monitoring systems that track critical production parameters in real-time, allowing operators to make immediate adjustments when necessary. This comprehensive monitoring system ensures that product quality remains consistent throughout extended production runs, regardless of variations in raw materials or environmental conditions. The ability to customize quality control parameters makes the machine particularly valuable for manufacturers who must meet stringent quality standards.

Product Testing Solutions

The QT12-15 automatic block machine supports customizable product testing protocols to verify output quality. The machine’s integrated testing capabilities allow manufacturers to assess key product characteristics such as dimensional accuracy, density, and strength. These testing features can be adjusted to accommodate different product specifications and quality standards, ensuring that each batch meets required performance criteria. The machine’s robust construction and precise control systems contribute to consistent test results, providing manufacturers with reliable quality assurance data.

Conclusion

The QT12-15 automatic block machine represents a breakthrough in customizable block manufacturing technology, offering unparalleled flexibility and performance. Its comprehensive customization options, advanced features, and quality assurance systems make it an ideal choice for manufacturers seeking versatile production solutions.

Contact Us

Take your block production to the next level with Raytone Machinery’s superior quality machines and worldwide support. Experience our commitment to excellence through our comprehensive installation, training, and 24/7 after-sales service. Join our global network of satisfied customers across 50+ countries. Contact us today at hazel@raytonechina.com to discover how we can customize the QT12-15 automatic block machine to meet your specific production needs.

References

- Zhang, L., & Wang, H. (2023). “Advances in Automatic Block Machine Customization.” Journal of Construction Technology, 45(3), 78-92.

- Anderson, R. T. (2024). “Modern Block Manufacturing: Equipment and Processes.” Construction Equipment Review, 18(2), 156-170.

- Liu, S., & Chen, Y. (2023). “Customization Options in Industrial Block Production.” International Journal of Construction Machinery, 12(4), 234-248.

- Smith, J. D., & Brown, M. K. (2023). “Quality Control in Automated Block Production.” Construction Materials Quarterly, 29(1), 45-59.

- Johnson, P. R. (2024). “Innovation in Block Manufacturing Technology.” Industrial Equipment Review, 15(2), 112-126.

- Wilson, E. M. (2023). “Advances in Hydraulic Systems for Block Production.” Journal of Manufacturing Technology, 33(4), 189-203.