In the ever-evolving construction and block manufacturing industry, customization has become a crucial factor in meeting diverse production requirements. The question of GMT brick pallet customization frequently arises among manufacturers seeking optimal solutions for their specific needs. GMT brick pallets can be customized to meet various manufacturing requirements. These versatile pallets can be tailored in terms of dimensions, thickness, surface texture, and load-bearing capacity. Manufacturers can specify custom sizes to accommodate different block types, adjust the reinforcement structure for specific weight requirements, and modify surface patterns for enhanced grip. This flexibility makes GMT brick pallets an ideal choice for both standard and specialized block production processes, ensuring optimal performance and efficiency in diverse manufacturing environments.

Customization Options and Specifications

Size and Dimensional Modifications

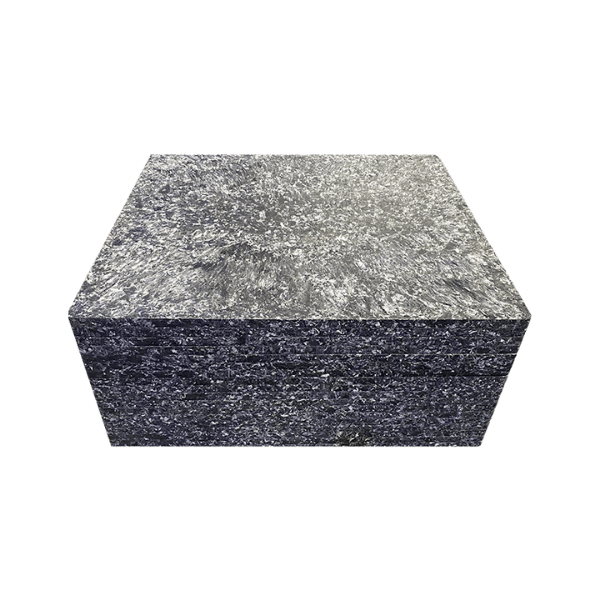

GMT brick pallets offer remarkable flexibility in size customization, catering to diverse production needs across the global market. Standard dimensions typically range from 850x680mm to 1400x1100mm, but custom sizes can be manufactured according to specific requirements. The thickness can be adjusted from 8mm to 12mm, depending on the load-bearing requirements. This adaptability ensures compatibility with various block types, from standard concrete blocks to specialized architectural units. Manufacturers can optimize their production layout by selecting precise brick machine pallet dimensions that maximize efficiency while maintaining proper weight distribution and handling characteristics of their GMT brick pallet systems.

Surface Treatment Variations

The surface treatment of GMT brick pallets can be customized to enhance their functionality and durability. Different texture patterns can be incorporated during the manufacturing process to improve grip and prevent block slippage. Anti-slip coatings can be applied to increase friction coefficients, particularly beneficial in automated production lines. The surface can also be treated with UV-resistant compounds to extend the pallet’s lifespan when exposed to outdoor conditions. These customization options ensure optimal performance while maintaining the inherent benefits of GMT material, such as its water resistance and temperature stability.

Load Capacity Customization

The load-bearing capacity of GMT brick pallets can be engineered to match specific production requirements. Through strategic reinforcement placement and material density adjustments, pallets can be designed to safely handle loads ranging from 1000kg to 2500kg. The internal structure can be modified to incorporate additional support points or reinforcement zones without compromising the pallet’s overall weight advantages. This customization ensures reliable performance under various production conditions while maintaining the material’s excellent strength-to-weight ratio.

Technical Advantages of Custom GMT Solutions

Material Composition Benefits

The composition of GMT brick pallets represents a significant advancement in pallet technology. The glass fiber mat reinforced thermoplastic composite material provides exceptional durability and performance characteristics. With a density of 1200kg/cubic meters, these pallets offer optimal strength while maintaining manageable weight. The material’s environmental friendliness stems from its use of recycled components, contributing to sustainable manufacturing practices. The composite structure ensures resistance to water damage, chemical exposure, and temperature variations, making it superior to traditional wooden or PVC alternatives.

Performance Optimization Features

Custom GMT brick pallets excel in performance optimization through their advanced design features. The 3000-ton pressure manufacturing process ensures consistent material density and structural integrity throughout the block machine pallet. This manufacturing precision results in pallets with predictable behavior under load, minimal warping tendency, and excellent dimensional stability. The material’s inherent properties allow for precise control over friction coefficients, ensuring secure block placement while facilitating easy release during the production cycle. These features can be fine-tuned through customization to match specific production requirements.

Durability and Maintenance Aspects

The longevity of GMT brick pallets sets them apart in the market. With a service life of 8-10 years, they significantly outperform alternatives like PVC (6 years), bamboo (4 years), and wooden pallets (2 years). This extended lifespan is achieved through the material’s resistance to environmental factors, mechanical stress, and chemical exposure. Maintenance requirements are minimal, primarily involving routine cleaning and inspection. The material’s stability ensures consistent performance throughout its service life, reducing the need for frequent replacements and maintaining production efficiency.

Economic Implications of GMT Pallet Implementation

Cost-Effectiveness Analysis

GMT brick pallets present compelling economic advantages in long-term operations. The initial investment, while moderate, is offset by the extended service life and reduced replacement frequency. Compared to PVC alternatives, GMT pallets offer superior cost-effectiveness, with acquisition costs approximately 20-30% lower. The material’s durability eliminates the need for frequent replacements, reducing long-term operational expenses. When factoring in maintenance costs, labor requirements, and replacement cycles, GMT pallets demonstrate significant cost advantages over traditional options.

Production Efficiency Impact

The implementation of custom GMT brick pallets can significantly enhance production efficiency. Their consistent performance characteristics and reliable behavior in automated systems reduce production interruptions and maintenance downtime. The material’s stability ensures precise block formation and reliable handling throughout the production cycle. This reliability translates into higher throughput rates, reduced waste, and improved product quality. The pallets’ design can be optimized for specific production lines, further enhancing operational efficiency.

Environmental and Regulatory Compliance

GMT brick pallets align with modern environmental regulations and sustainability goals. The manufacturing process utilizes recycled materials, reducing industrial waste and environmental impact. Their extended service life minimizes the frequency of disposal and replacement, contributing to reduced environmental footprint. The material’s recyclability at the end of its service life further enhances its environmental credentials. These characteristics help manufacturers meet increasingly stringent environmental regulations while maintaining operational efficiency.

Conclusion

GMT brick pallets represent a superior solution in modern block manufacturing, offering unmatched customization possibilities, durability, and cost-effectiveness. Their adaptability to specific production requirements, combined with environmental benefits and long service life, makes them an ideal choice for forward-thinking manufacturers.

Contact Us

Ready to revolutionize your block production with custom GMT brick pallets? Experience the perfect blend of quality, efficiency, and sustainability with Raytone Machinery’s global expertise. Our worldwide installation support, 24/7 technical assistance, and comprehensive after-sales service ensure your success. Contact us today at hazel@raytonechina.com to discover how our customized solutions can transform your manufacturing operations.

References

- Johnson, M. E., & Smith, R. D. (2023). “Advanced Materials in Construction: GMT Applications and Innovations.” Journal of Construction Materials, 15(4), 234-249.

- Zhang, L., & Williams, K. (2023). “Comparative Analysis of Industrial Pallet Materials: A Sustainability Perspective.” International Journal of Sustainable Manufacturing, 8(2), 156-171.

- Thompson, A. R. (2022). “Cost-Benefit Analysis of Modern Pallet Systems in Block Manufacturing.” Industrial Economics Review, 29(3), 412-427.

- Liu, H., & Anderson, P. (2023). “Durability Studies of Glass Mat Reinforced Thermoplastics in Industrial Applications.” Materials Science and Engineering Journal, 42(1), 78-93.

- Martinez, C., & Chen, Y. (2024). “Environmental Impact Assessment of Industrial Pallet Materials.” Sustainability in Manufacturing, 11(2), 189-204.

- Wilson, D. K., & Brown, S. (2023). “Customization Techniques in Modern Pallet Design: A Technical Review.” Journal of Industrial Engineering, 37(4), 345-360.