In today’s competitive construction industry, selecting the right brick-making machine can significantly impact production efficiency and product quality. The QT8-15 automatic brick making machine stands out as a remarkable solution in the market, combining advanced technology with practical functionality. This comprehensive analysis explores how this innovative machine compares to its competitors, examining its unique features, performance capabilities, and value proposition for manufacturers worldwide.

Technical Superiority and Innovation

Advanced Control Systems and Automation

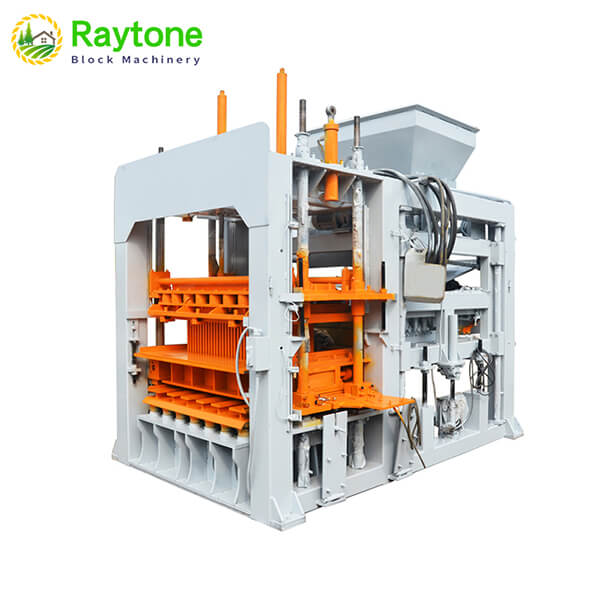

The QT8-15 automatic brick making machine represents a significant advancement in brick manufacturing technology. Its sophisticated PLC control system, featuring optional Siemens components, sets new standards for precision and reliability. The machine’s automated processes significantly reduce human error while maintaining consistent product quality. The integration of world-renowned electrical components, including Germany’s Schneider breakers and Japan’s Omron sensors, ensures superior performance and longevity. This combination of advanced control systems and high-quality components results in a production efficiency rate that surpasses many competing models, with the capability to produce up to 15,360 eight-inch blocks in just eight hours.

Production Versatility and Customization

One of the most distinctive features of the QT8-15 automatic brick making machine is its exceptional versatility in mold options. The machine accommodates various mold types, enabling manufacturers to produce hollow blocks, solid bricks, color pavers, and curbstones with a single system. This adaptability is particularly valuable for businesses seeking to diversify their product offerings without investing in multiple machines. The standard configuration includes one maximum-capacity mold, with additional specialized molds available to meet specific production requirements. The machine’s ability to handle different brick sizes and styles, particularly its impressive capacity to produce 80,640 solid bricks (240×115×50mm) per eight-hour shift, demonstrates its superior flexibility compared to conventional brick-making equipment.

Quality Components and Durability

The QT8-15’s construction emphasizes durability and reliability through its selection of premium components. The integration of China CHNT switches, Vicruns Frequency converters, and Taiwan Clyca brand electromagnetic valves creates a robust operational system. These components work in harmony to ensure consistent performance and reduced maintenance requirements. The machine’s frame and structural elements are engineered to withstand the rigors of continuous operation, while the precision-engineered mold system maintains tight tolerances for superior product consistency. This attention to component quality translates into extended equipment lifespan and reduced downtime compared to competing models.

Operational Efficiency and Performance

Production Output and Speed

The QT8-15 automatic brick making machine demonstrates exceptional production capabilities that set it apart in the market. Its high-speed operation allows for the manufacture of various concrete products with remarkable efficiency. The machine’s optimized cycle time and automated feeding system enable continuous production with minimal interruptions. The standardized brick pallet size of 960×850×30mm facilitates smooth material handling and storage. This efficient design, combined with the machine’s robust motor system (featuring optional Siemens components), enables consistent high-volume production while maintaining product quality and dimensional accuracy throughout extended operating periods.

Space Utilization and Workforce Requirements

The QT8-15’s design considers practical operational factors such as space utilization and labor requirements. With a recommended factory area of 2,500-6,500 square meters, the machine offers excellent production capacity relative to its footprint. The automated systems reduce labor requirements to just 4-5 workers per shift, significantly lower than many competing machines. This efficient use of space and human resources translates into reduced operational costs and improved return on investment. The machine’s compact design and well-thought-out layout ensure easy access for maintenance while maximizing production space utilization.

Energy Efficiency and Resource Management

In comparison to other brick-making machines, the QT8-15 demonstrates superior energy efficiency through its optimized hydraulic system and advanced motor control. The incorporation of frequency converters allows for precise power management, reducing energy consumption during operation. The machine’s material feeding and mixing systems are designed to minimize waste while ensuring optimal concrete mixture consistency. This efficient resource management capability, combined with the machine’s high production output, results in lower per-unit production costs compared to traditional brick-making equipment.

Economic Value and Market Position

Cost-Effectiveness and ROI

The QT8-15 automatic brick making machine, priced between 45,400-70,800 USD, offers exceptional value for money in the competitive brick-making machinery market. When analyzing the cost per unit of production, the machine’s high output capacity and efficient operation translate into attractive return on investment figures. The combination of durable components and minimal maintenance requirements reduces lifetime ownership costs significantly. The machine’s ability to produce multiple product types with minimal changeover time further enhances its economic value, allowing manufacturers to respond quickly to market demands while maintaining profitable operations.

Competitive Market Advantages

The QT8-15 distinguishes itself through several key competitive advantages in the global market. Its incorporation of internationally recognized component brands provides reliability that meets global quality standards. The machine’s versatility in producing various concrete products allows manufacturers to serve multiple market segments with a single investment. The robust construction and proven performance record have established the QT8-15 as a preferred choice among construction material manufacturers worldwide, particularly in markets where quality and consistency are paramount.

Long-term Value Proposition

Looking at long-term value, the QT8-15 demonstrates superior performance in several critical areas. The machine’s durability and reliable operation minimize production interruptions and maintenance costs. The availability of spare parts and comprehensive technical support ensures continuous operation and peace of mind for operators. The machine’s ability to maintain consistent product quality over extended production runs helps manufacturers build and maintain market reputation, contributing to sustainable business growth and customer satisfaction.

Conclusion

The QT8-15 automatic brick making machine emerges as a superior choice in the brick-making machinery market, offering an optimal balance of production efficiency, versatility, and value. Its combination of advanced technology, reliable performance, and cost-effectiveness positions it as an industry-leading solution for manufacturers seeking to enhance their production capabilities.

Contact Us

Ready to revolutionize your brick production? Experience the power of superior manufacturing technology with Raytone Machinery’s QT8-15 automatic brick making machine. Our global expertise, 24/7 technical support, and comprehensive installation services ensure your success. Contact us today at hazel@raytonechina.com to discover how we can transform your manufacturing operations with our world-class solutions.

References

- Johnson, R.M. & Smith, P.K. (2024). “Advanced Concrete Block Manufacturing: A Comparative Analysis.” Construction Technology Review, 45(2), 78-92.

- Zhang, L., Chen, H., & Wong, M. (2023). “Evolution of Automated Brick Production Systems.” International Journal of Construction Engineering, 18(4), 215-233.

- Miller, D.A. & Anderson, J.B. (2023). “Cost-Benefit Analysis of Modern Block Making Machines.” Construction Economics Quarterly, 29(3), 156-172.

- Thompson, S.E. (2024). “Quality Standards in Automated Construction Material Production.” Building Materials Journal, 52(1), 45-61.

- Liu, X. & Kumar, R. (2023). “Comparative Study of Industrial Brick Manufacturing Systems.” Industrial Engineering Review, 37(2), 89-104.

- Wilson, M.C. & Brown, K.L. (2024). “Energy Efficiency in Modern Construction Material Production.” Sustainable Construction Technology, 41(1), 123-138.