Cement block making machines are essential tools in the construction industry, revolutionizing the way we produce building materials. These versatile machines efficiently manufacture concrete blocks, pavers, and other precast elements, streamlining construction processes and reducing labor costs. Whether you’re a seasoned contractor or a newcomer to the field, understanding the ins and outs of cement block making machines is crucial for maximizing productivity and quality in your projects. In this comprehensive guide, we’ll explore the types of machines available, their key features, and the benefits they bring to modern construction practices, helping you make informed decisions for your building needs.

Types of Cement Block Making Machines

Manual Block Making Machines

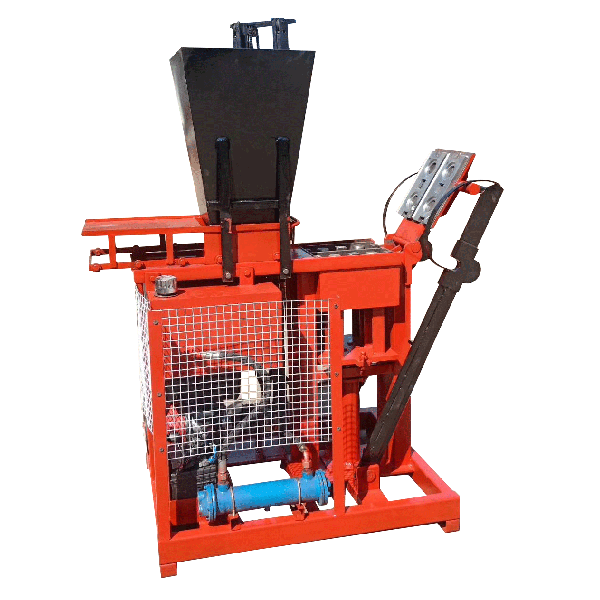

Manual block making machines are simple, low-cost equipment ideal for small-scale production needs. These machines require human power to perform operations such as filling the mold, compacting, and removing the blocks. They are often used in remote areas or developing regions where electricity access is limited. Despite their basic design, manual machines can produce durable and uniform cement blocks when used properly. They are favored by small construction firms, rural builders, and DIY enthusiasts for local housing projects and community infrastructure development.

Semi-Automatic Block Making Machines

Semi-automatic cement block making machines provide an efficient balance between manual effort and automation. These machines generally incorporate electric motors or hydraulic systems to automate certain functions like material mixing, vibration, or block ejection, while still requiring manual feeding or mold handling. This design increases production speed and consistency compared to purely manual machines. Semi-automatic cement block making machines are widely used by medium-sized construction companies aiming to enhance productivity, reduce labor costs, and maintain flexibility in operations without investing in fully automated systems.

Fully Automatic Block Making Machines

Fully automatic block making machines represent the highest level of efficiency and technology in cement block production. These advanced systems automate all stages, including material batching, feeding, mixing, molding, compaction, and block ejection, with minimal human supervision. They ensure high production rates, uniform block quality, and reduced operational costs over time. Fully automatic machines are ideal for large-scale block manufacturing facilities and major construction companies that require high output volumes, consistent product standards, and efficient use of resources to meet demanding project schedules.

Key Features of Modern Cement Block Making Machines

Advanced Vibration Technology

Modern cement block making machines utilize sophisticated vibration technology to achieve optimal compaction of the concrete mixture. This advanced vibration system enhances the density and strength of the blocks, resulting in durable and high-quality finished products. Some machines feature adjustable vibration frequencies, enabling operators to customize the compaction process according to different block types, sizes, and concrete mix formulations. This flexibility ensures superior surface finish and structural integrity, meeting the rigorous demands of various construction applications.

Precision Mold Systems

At the core of modern block making machines lies the precision mold system, designed to produce blocks with exact dimensions and crisp, well-defined edges. These molds are engineered with high accuracy to ensure consistent block quality and uniformity. Many manufacturers offer interchangeable molds, allowing users to easily switch between different block shapes and sizes without replacing the entire machine. This adaptability provides contractors and manufacturers with the flexibility needed to satisfy diverse project specifications while maximizing equipment utilization.

Intelligent Control Systems

State-of-the-art cement block making machines are equipped with intelligent control systems that significantly improve production efficiency and product consistency. These systems often integrate programmable logic controllers (PLCs) that provide precise control over mixing, molding, vibration, and curing processes. User-friendly touch-screen interfaces simplify operation, while features like recipe management and real-time production data tracking enable operators to monitor and optimize performance. This intelligent automation reduces human error, enhances quality control, and streamlines overall manufacturing workflows.

Benefits of Investing in a Cement Block Making Machine

Increased Production Efficiency

Investing in a cement block making machine significantly enhances production efficiency by enabling rapid and continuous block manufacturing. Depending on the machine’s automation level and capacity, hundreds to thousands of blocks can be produced daily. This increased output allows construction firms to meet tight deadlines, scale operations, and undertake larger projects without delays. Additionally, automated processes reduce manual labor and human error, streamlining workflows and improving overall productivity on-site or in manufacturing facilities.

Consistent Quality Control

Cement block making machines provide precise control over every stage of production, including material mixing, compaction, and molding. This precision ensures that each block maintains uniform strength, exact dimensions, and a consistent surface finish. Such quality consistency is vital for structural integrity and aesthetic uniformity in construction projects. By minimizing variations and defects, these machines reduce the likelihood of weak or irregular blocks, thereby enhancing the durability, safety, and visual appeal of buildings and infrastructure.

Cost-Effective Construction Solutions

Though purchasing a cement block making machine requires an upfront investment, it often results in substantial long-term cost savings. Producing blocks on-site reduces transportation expenses and lowers the risk of damage during shipping. Furthermore, manufacturing blocks as needed minimizes material waste and inventory costs. The ability to customize block size and shape allows for optimized building designs, improving construction efficiency. Collectively, these factors contribute to more economical construction processes and better resource management across projects.

Conclusion

Cement block making machines have become indispensable tools in modern construction, offering unparalleled efficiency, quality, and versatility. From manual options suited for small-scale operations to fully automatic systems capable of industrial-scale production, there’s a machine to fit every project need and budget. By investing in the right cement block making machine, construction professionals can significantly enhance their productivity, maintain high-quality standards, and stay competitive in an ever-evolving industry.

Contact Us

At Raytone Machinery, we’re committed to providing top-tier cement block making machines that meet the diverse needs of our global clientele. Our range of products, from manual to fully automatic systems, is designed to deliver exceptional performance, reliability, and value. Experience the Raytone difference and elevate your construction projects to new heights. For more information about our cement block making machines and how they can benefit your business, contact us at hazel@raytonechina.com.

References

- Johnson, M. (2022). Advancements in Concrete Block Manufacturing Technology. Construction Engineering Quarterly.

- Smith, A. & Brown, L. (2021). Comparative Analysis of Manual vs. Automatic Block Making Machines. Journal of Construction Materials.

- Chen, X. (2023). The Impact of Vibration Technology on Concrete Block Quality. International Concrete Research.

- Williams, R. (2022). Cost-Benefit Analysis of On-Site Block Production. Construction Economics Review.

- Garcia, E. et al. (2023). Sustainability in Concrete Block Production: A Case Study. Green Building Materials Journal.

- Taylor, S. (2021). Quality Control Measures in Modern Block Manufacturing. Building Standards Institute Annual Report.