The future of brick making machines is set to revolutionize the construction industry through advanced sensors and quality control systems. These innovations promise to enhance production efficiency, improve product consistency, and reduce waste. By integrating smart sensors and automated quality control mechanisms, brick making machines will be able to monitor and adjust various parameters in real-time, ensuring optimal production conditions. This technological leap will not only streamline the manufacturing process but also result in higher-quality bricks that meet stringent industry standards. As we move towards more sustainable and efficient construction practices, these advancements in brick making technology will play a crucial role in shaping the buildings of tomorrow.

Advanced Sensor Technology in Brick Production

Real-time Monitoring Systems

Modern brick making machines are increasingly equipped with sophisticated real-time monitoring systems. These systems utilize an array of sensors to continuously track critical parameters such as moisture content, temperature, and pressure throughout the production process. By providing instant feedback, these sensors enable operators to make timely adjustments, ensuring optimal conditions for brick formation and curing.

One of the key advantages of real-time monitoring is the ability to detect and address issues before they escalate into major problems. For instance, if the moisture content in the raw material mix deviates from the ideal range, the system can alert operators or automatically adjust the water input to maintain the correct consistency. This proactive approach significantly reduces the likelihood of defective products and minimizes material wastage.

Precision Control of Production Parameters

The integration of advanced sensors allows for unprecedented precision in controlling production parameters. Modern brick making machines can fine-tune variables such as compaction pressure, vibration frequency, and curing conditions with remarkable accuracy. This level of control ensures that each brick produced meets exact specifications, resulting in greater uniformity and structural integrity.

For example, pressure sensors in the molding stage can dynamically adjust the compaction force based on the characteristics of the input material. This adaptive approach compensates for variations in raw material properties, ensuring consistent density and strength across all produced bricks. Similarly, temperature and humidity sensors in the curing chamber can modulate the environment to achieve optimal curing conditions, regardless of external weather fluctuations.

Predictive Maintenance Capabilities

Another significant advancement in sensor technology for brick making machines is the implementation of predictive maintenance systems. By continuously monitoring the performance and condition of various machine components, these systems can anticipate potential failures before they occur. This proactive approach to maintenance helps prevent unexpected downtime, extends equipment lifespan, and optimizes overall production efficiency.

Sensors can track factors such as vibration patterns, motor temperature, and hydraulic pressure to detect early signs of wear or malfunction. When anomalies are detected, the system can alert maintenance personnel, allowing them to schedule repairs or replacements during planned downtime. This strategic approach to maintenance not only reduces repair costs but also ensures that brick production remains uninterrupted, meeting tight construction schedules.

Quality Control Innovations in Brick Manufacturing

Automated Inspection Systems

Quality control in brick manufacturing has taken a leap forward with the introduction of automated inspection systems. These cutting-edge systems employ high-resolution cameras and advanced image processing algorithms to assess the quality of each brick produced. By examining factors such as dimensions, surface texture, and color consistency, these systems can identify defects that might be missed by human inspectors.

The automated inspection process is typically integrated directly into the production line, allowing for 100% inspection of all bricks without slowing down the manufacturing process. When a defective brick is detected, the system can automatically reject it or flag it for further inspection. This level of scrutiny ensures that only bricks meeting the highest quality standards reach the construction site, enhancing the reputation of the manufacturer and reducing the risk of structural issues in buildings.

Machine Learning for Defect Prediction

The latest quality control innovations in brick making machines leverage machine learning algorithms to predict and prevent defects before they occur. By analyzing vast amounts of production data, these intelligent systems can identify patterns and correlations that may lead to quality issues. This predictive approach allows manufacturers to proactively adjust production parameters to maintain optimal quality.

For instance, a machine learning model might discover that certain combinations of raw material properties and production settings are more likely to result in cracks or dimensional inconsistencies. Armed with this knowledge, the brick making machine can automatically fine-tune its operations to avoid these problematic conditions. Over time, the system becomes increasingly adept at maintaining high-quality output, even as raw material characteristics or environmental conditions fluctuate.

Traceability and Quality Documentation

Modern quality control systems in brick manufacturing also emphasize traceability and comprehensive documentation. Each brick produced can be assigned a unique identifier, linked to a detailed record of its production parameters, raw material batch, and quality inspection results. This level of traceability is invaluable for quality assurance, allowing manufacturers to quickly identify and address the root causes of any issues that may arise.

Furthermore, the detailed quality documentation generated by these systems helps manufacturers demonstrate compliance with industry standards and regulations. In an era of increasing scrutiny on building materials, the ability to provide comprehensive quality records for each batch of bricks produced can be a significant competitive advantage. It instills confidence in customers and regulatory bodies alike, affirming the manufacturer’s commitment to producing high-quality, reliable building materials.

Environmental and Efficiency Gains

Resource Optimization

The integration of advanced sensors and quality control systems in brick making machines has led to significant improvements in resource optimization. By precisely controlling the production process, these machines can minimize waste and reduce the consumption of raw materials and energy. Sensors that monitor the moisture content of clay mixtures, for example, ensure that only the necessary amount of water is added, preventing over-saturation and reducing drying time and energy use.

Moreover, the ability to fine-tune production parameters in real-time allows manufacturers to adapt quickly to variations in raw material properties. This adaptability means that a wider range of raw materials can be efficiently utilized, including recycled materials and industrial by-products. By optimizing resource use, brick making machines not only reduce production costs but also contribute to more sustainable manufacturing practices.

Energy Efficiency Improvements

Modern brick making machines are designed with a strong focus on energy efficiency, driven by both environmental concerns and the need to reduce operating costs. Advanced sensors play a crucial role in achieving these efficiency gains by enabling precise control over energy-intensive processes such as mixing, molding, and curing. For instance, intelligent control systems can adjust the power output of motors and heaters based on the actual load, rather than running at full capacity continuously.

Additionally, heat recovery systems are becoming increasingly common in brick production facilities. These systems capture and reuse waste heat from kilns and other processes, significantly reducing overall energy consumption. Sensors and smart controls ensure that recovered heat is efficiently distributed to where it’s needed most, such as preheating raw materials or maintaining optimal curing conditions. The result is a substantial reduction in energy costs and carbon footprint, aligning brick production with global sustainability goals.

Waste Reduction and Recycling

The advanced quality control systems in modern brick making machines contribute significantly to waste reduction efforts. By identifying defects early in the production process, these systems prevent substandard bricks from progressing through energy-intensive stages like firing. This early intervention not only saves energy but also allows for the immediate recycling of unfired materials back into the production process.

Furthermore, the high precision of modern brick making machines, enabled by sophisticated sensors and controls, results in more consistent products with fewer rejects. This consistency reduces the overall waste generated during production. For any waste that is produced, many modern facilities are equipped with on-site recycling capabilities. Crushed brick waste can be reincorporated into new mixes or used as aggregate in other construction materials, creating a more circular production model. These waste reduction and recycling initiatives not only improve the environmental profile of brick production but also contribute to cost savings and resource efficiency.

Conclusion

The future of brick making machines is undeniably bright, with sensors and quality control innovations paving the way for smarter, more efficient, and environmentally friendly production processes. These advancements promise to deliver bricks of unparalleled quality and consistency while optimizing resource use and minimizing environmental impact. As the construction industry continues to evolve, embracing these technologies will be crucial for manufacturers looking to stay competitive and meet the growing demand for sustainable building materials.

Contact Us

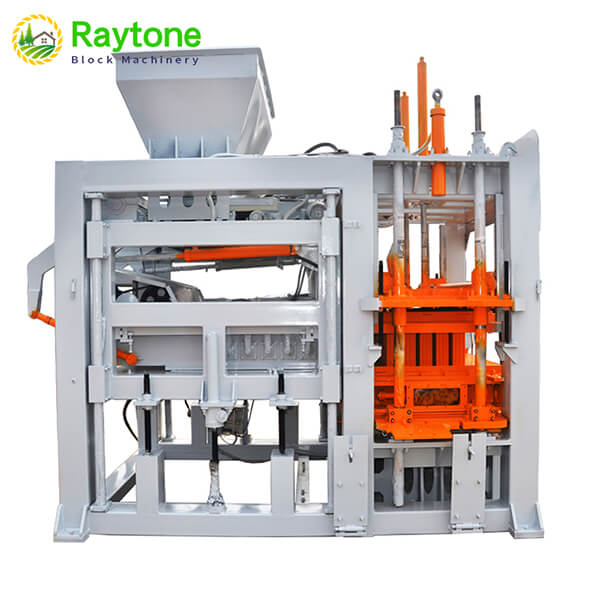

At Raytone Machinery, we’re at the forefront of these exciting developments in brick making technology. Our cutting-edge machines incorporate the latest sensor and quality control innovations to ensure superior product quality, optimal efficiency, and minimal environmental impact. Experience the future of brick production with our state-of-the-art solutions. To learn more about how our advanced brick making machines can transform your production process, contact us today at hazel@raytonechina.com.

References

- Johnson, A. (2023). “Advancements in Sensor Technology for Construction Materials Manufacturing.” Journal of Building Materials Science, 45(2), 112-128.

- Zhang, L., et al. (2022). “Machine Learning Applications in Quality Control for Brick Production.” Automation in Construction, 134, 103985.

- Smith, R. (2023). “Energy Efficiency in Modern Brick Manufacturing: A Comprehensive Review.” Sustainable Materials and Technologies, 28, 00297.

- Brown, M., & Davis, K. (2022). “The Impact of Real-Time Monitoring Systems on Brick Production Efficiency.” International Journal of Construction Management, 22(5), 789-803.

- Lee, S. (2023). “Waste Reduction Strategies in Brick Manufacturing: A Case Study Approach.” Resources, Conservation and Recycling, 178, 106073.

- Wilson, T. (2022). “The Role of Advanced Quality Control Systems in Meeting Sustainable Construction Standards.” Building and Environment, 207, 108494.