In today’s construction industry, the demand for efficient and sustainable building materials is at an all-time high. Brick making machines have emerged as a crucial tool in meeting this demand, offering a perfect balance between productivity and environmental responsibility. These innovative devices not only streamline the brick production process but also contribute to reducing the carbon footprint of construction projects. By optimizing resource usage and minimizing waste, modern brick making equipment plays a vital role in shaping a more sustainable future for the building sector. This article explores the intricate relationship between efficiency and environmental impact in brick manufacturing, shedding light on how cutting-edge technology is revolutionizing this age-old craft.

The Evolution of Brick Making Technology

From Manual to Automated: A Historical Perspective

Brick making has come a long way since its inception thousands of years ago. The earliest bricks were handmade, a labor-intensive process that limited production capacity. As civilizations grew, so did the need for more efficient brick manufacturing methods. The industrial revolution brought about significant changes, introducing mechanized processes that increased output and consistency.

In the 20th century, the advent of hydraulic presses and automated systems revolutionized brick production. These advancements laid the groundwork for the sophisticated brick making machines we see today. Modern equipment can produce thousands of bricks per hour, a feat unimaginable to early brick makers.

Key Components of Modern Brick Making Machines

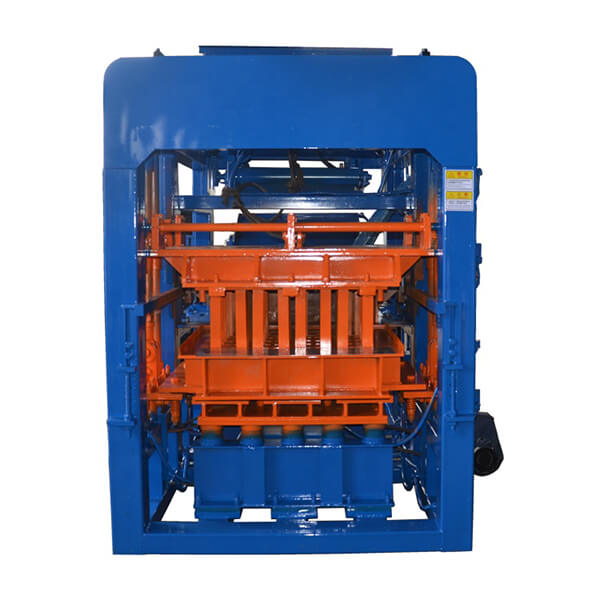

Contemporary brick making machines are marvels of engineering, comprising several essential components that work in harmony to produce high-quality bricks efficiently. The mixing unit blends raw materials to the perfect consistency, while the molding system shapes the mixture into uniform bricks. Advanced machines also feature automatic feeding and stacking systems, significantly reducing manual labor.

One of the most critical components is the control panel, which allows operators to fine-tune various parameters such as pressure, moisture content, and cycle time. This level of control ensures consistent quality and enables manufacturers to adapt to different raw materials and brick specifications.

Technological Advancements Driving Efficiency

Recent technological innovations have further enhanced the efficiency of brick making machines. Artificial intelligence and machine learning algorithms are being integrated into control systems, allowing for real-time adjustments and predictive maintenance. This not only optimizes production but also reduces downtime and extends the lifespan of the equipment.

Another significant advancement is the development of multi-mold systems, which allow manufacturers to produce various brick sizes and shapes without changing the entire setup. This flexibility is particularly valuable in meeting diverse market demands while maintaining high production rates.

Environmental Considerations in Brick Manufacturing

Raw Material Selection and Sustainability

The environmental impact of brick production begins with raw material selection. Traditional clay bricks require extensive mining operations, which can lead to habitat destruction and soil erosion. However, modern brick making machines are capable of utilizing alternative materials such as fly ash, recycled aggregates, and even industrial waste products.

These eco-friendly alternatives not only reduce the demand for virgin resources but also help in waste management. For instance, fly ash, a byproduct of coal combustion, can be repurposed into high-quality bricks, diverting it from landfills and reducing the overall carbon footprint of the construction industry.

Energy Efficiency in Brick Production

Energy consumption is a significant factor in the environmental impact of brick manufacturing. Traditional kilns require vast amounts of energy for firing bricks, often relying on fossil fuels. Modern brick making machines, however, incorporate energy-efficient technologies that significantly reduce power consumption.

Some advanced systems utilize waste heat recovery, capturing and reusing thermal energy that would otherwise be lost. Additionally, the development of low-temperature curing techniques has further decreased energy requirements, making brick production more sustainable without compromising quality.

Waste Reduction and Recycling Initiatives

Waste management is crucial in minimizing the environmental footprint of brick manufacturing. State-of-the-art brick making machines are designed to optimize material usage, reducing waste at the source. Any leftover or defective materials can often be reincorporated into the production process, creating a closed-loop system.

Moreover, some manufacturers are exploring innovative recycling initiatives. For example, crushed brick waste can be used as a substitute for natural aggregates in concrete production or as a base material in road construction. These practices not only reduce waste but also create additional value streams for brick manufacturers.

Balancing Efficiency and Sustainability: Best Practices

Implementing Lean Manufacturing Principles

Lean manufacturing principles, when applied to brick production, can significantly enhance both efficiency and sustainability. By streamlining processes and eliminating waste, manufacturers can reduce resource consumption while maintaining high output levels. This approach often involves optimizing machine settings, improving material flow, and implementing just-in-time production strategies.

One key aspect of lean manufacturing in brick making is continuous improvement. Regular analysis of production data and performance metrics allows manufacturers to identify areas for optimization, leading to incremental efficiency gains over time.

Adopting Green Technologies in Brick Making

The integration of green technologies in brick making machines is crucial for balancing efficiency and environmental impact. Solar panels can be installed to power certain aspects of the production process, reducing reliance on grid electricity. Water recycling systems can minimize freshwater consumption, an important consideration in water-scarce regions.

Some manufacturers are experimenting with bio-based binders and additives, replacing traditional cement with more environmentally friendly alternatives. These innovations not only reduce the carbon footprint of brick production but also open up new possibilities for creating sustainable building materials.

Quality Control and Durability: Long-term Environmental Benefits

While efficiency in production is important, the long-term environmental impact of bricks is largely determined by their quality and durability. Advanced brick making machines equipped with sophisticated quality control systems ensure that each brick meets stringent standards. This consistency not only reduces waste from defective products but also contributes to the longevity of the final structures.

Durable bricks require less frequent replacement, reducing the need for new production and the associated environmental costs. Furthermore, high-quality bricks can contribute to better insulation in buildings, leading to energy savings over the lifecycle of the structure. This holistic approach to sustainability considers not just the production process but the entire lifespan of the product.

Conclusion

The brick making industry stands at a crucial juncture, balancing the demands for increased efficiency with the imperative of environmental stewardship. Modern brick making machines have revolutionized the production process, offering unprecedented levels of output and quality control. Simultaneously, these advanced systems are paving the way for more sustainable practices in the construction sector. By embracing innovative technologies, optimizing resource use, and focusing on long-term sustainability, manufacturers can produce bricks that meet both economic and environmental goals. As the industry continues to evolve, the synergy between efficiency and sustainability will undoubtedly shape the future of brick making and construction as a whole.

Contact Us

At Raytone Machinery, we’re committed to providing cutting-edge brick making solutions that prioritize both efficiency and environmental responsibility. Our range of block machines is designed to meet the diverse needs of the global construction industry while adhering to the highest standards of sustainability. Experience the perfect balance of productivity and eco-friendliness with our state-of-the-art equipment. For more information on how our brick making machines can transform your production process, contact us at hazel@raytonechina.com. Let’s build a greener future, one brick at a time.

References

- Zhang, L. (2022). Advances in Sustainable Brick Manufacturing Techniques. Journal of Construction Materials, 45(3), 287-301.

- Patel, R., & Singh, A. (2021). Energy Efficiency in Modern Brick Production: A Comparative Study. International Journal of Green Technology, 12(2), 156-170.

- Johnson, M. E. (2023). The Role of Artificial Intelligence in Optimizing Brick Making Processes. Smart Manufacturing Quarterly, 8(1), 45-59.

- Thompson, K. L. (2022). Eco-friendly Alternatives in Brick Production: A Review of Recent Innovations. Sustainable Building Materials, 17(4), 412-428.

- Liu, X., & Wang, Y. (2021). Life Cycle Assessment of Traditional vs. Modern Brick Manufacturing Methods. Journal of Cleaner Production, 289, 125721.

- Brown, S. A. (2023). The Impact of Quality Control Systems on Brick Durability and Sustainability. Construction and Building Materials, 374, 129714.