Efficient brick making machine setups are revolutionizing the construction industry, offering unparalleled productivity and cost-effectiveness for projects of all scales. These advanced systems combine cutting-edge technology with precision engineering to streamline the brick production process, enabling construction firms to meet tight deadlines and maintain high-quality standards. By integrating automated features, optimized mold designs, and intelligent control systems, modern brick making machines significantly reduce labor costs, minimize material waste, and ensure consistent output. This comprehensive guide explores the key components, setup considerations, and benefits of implementing efficient brick making machine setups in your construction projects, empowering you to make informed decisions and boost your operational efficiency.

Key Components of an Efficient Brick Making Machine Setup

Advanced Mixing and Molding Systems

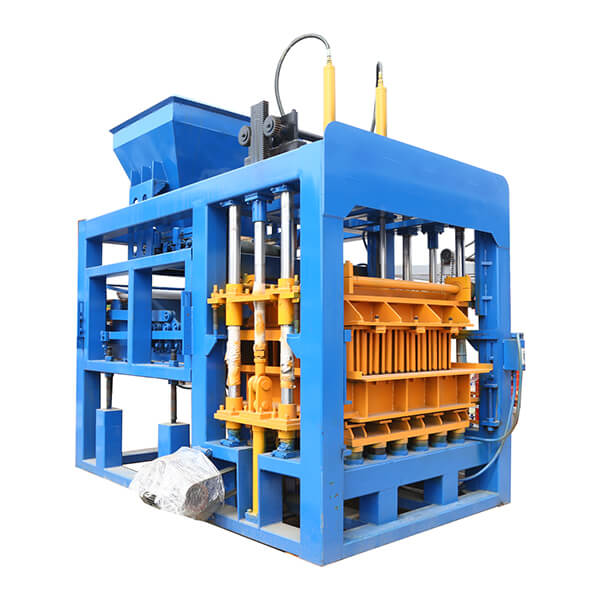

At the heart of any efficient brick making machine setup lies a sophisticated mixing and molding system. These components work in tandem to ensure the perfect consistency and shape of each brick produced. Advanced mixers utilize high-speed blades and precision controls to blend raw materials thoroughly, creating a homogeneous mixture that results in stronger, more durable bricks. The molding system, equipped with interchangeable molds, allows for versatility in brick sizes and shapes, catering to diverse project requirements.

Modern brick making machines often incorporate vibration technology in their molding process. This feature enhances brick density and reduces air pockets, resulting in a more consistent and higher-quality end product. Additionally, some setups include automated mold release mechanisms, which significantly speed up production cycles and reduce the risk of brick damage during extraction.

Automated Material Handling and Conveyor Systems

Efficient brick making setups rely heavily on automated material handling and conveyor systems to maintain a smooth, continuous production flow. These systems transport raw materials from storage silos to the mixing area, then move the mixed compound to the molding station, and finally carry the freshly molded bricks to curing areas or palletizing stations.

Advanced conveyor systems are designed with durability and ease of maintenance in mind, often featuring modular components that can be quickly replaced or repaired. Some setups incorporate smart sensors and monitoring devices that track material flow, alerting operators to potential bottlenecks or equipment issues before they can disrupt production.

Intelligent Control and Monitoring Systems

The integration of intelligent control and monitoring systems is crucial for maximizing the efficiency of brick making machine setups. These systems typically include programmable logic controllers (PLCs) that oversee and coordinate all aspects of the production process. Operators can easily adjust parameters such as mixing times, vibration intensity, and curing conditions through user-friendly interfaces, ensuring optimal brick quality across different material batches or environmental conditions.

Advanced monitoring systems also play a vital role in quality control and maintenance. They can track key performance indicators in real-time, such as production rates, material consumption, and energy usage. This data allows for continuous process optimization and helps predict maintenance needs, reducing downtime and extending the lifespan of the equipment.

Optimizing Brick Making Machine Setups for Maximum Efficiency

Customizing Machine Configurations

To achieve peak efficiency, it’s essential to customize your brick making machine setup to suit your specific production needs and environmental conditions. This may involve selecting the appropriate machine capacity, choosing between hydraulic or mechanical press systems, and determining the ideal level of automation for your operation. Consider factors such as your target production volume, the types of bricks you’ll be producing, and the available space in your facility when configuring your setup.

Some manufacturers offer modular brick making machine designs that allow for easy expansion or reconfiguration as your production needs evolve. This flexibility can be particularly valuable for growing businesses or those that frequently switch between different brick types or sizes.

Implementing Efficient Material Management

Efficient material management is crucial for maintaining high productivity in brick making operations. This involves not only the proper storage and handling of raw materials but also optimizing the mix design to achieve the desired brick properties while minimizing waste. Advanced brick making setups often incorporate automated batching systems that precisely measure and dispense materials according to pre-programmed recipes, ensuring consistency across production runs.

Additionally, implementing a robust inventory management system can help prevent production delays due to material shortages and reduce excess inventory costs. Some modern setups integrate with enterprise resource planning (ERP) systems, allowing for real-time tracking of material usage and automated reordering of supplies when stocks run low.

Enhancing Energy Efficiency

Improving the energy efficiency of your brick making machine setup not only reduces operational costs but also minimizes environmental impact. Modern machines often incorporate energy-saving features such as variable frequency drives (VFDs) on motors, which adjust power consumption based on the current load. Optimizing curing processes through the use of energy-efficient kilns or natural drying techniques can also significantly reduce energy consumption.

Some manufacturers are exploring innovative technologies like solar-powered brick making machines or systems that recover and reuse waste heat from the production process. These advancements not only improve energy efficiency but can also provide a competitive edge in markets that prioritize sustainable construction practices.

Maximizing ROI with Efficient Brick Making Machine Setups

Analyzing Production Metrics

To truly maximize the return on investment (ROI) from your brick making machine setup, it’s crucial to continuously analyze production metrics. Modern setups often come equipped with comprehensive data collection and analysis tools that provide insights into every aspect of the production process. Key performance indicators (KPIs) to monitor include production rate, material consumption efficiency, energy usage per brick, and quality consistency.

By regularly reviewing these metrics, you can identify areas for improvement and make data-driven decisions to optimize your operations. For example, you might discover that adjusting the mixing time or vibration intensity could lead to improved brick quality without significantly impacting production speed. Some advanced systems even incorporate machine learning algorithms that can suggest optimization strategies based on historical performance data.

Implementing Preventive Maintenance Strategies

An efficient brick making machine setup is only as good as its maintenance program. Implementing a robust preventive maintenance strategy can significantly reduce downtime, extend equipment lifespan, and ensure consistent production quality. Modern setups often include built-in diagnostics and predictive maintenance features that can alert operators to potential issues before they lead to breakdowns.

Developing a comprehensive maintenance schedule that includes regular inspections, lubrication, and replacement of wear parts is essential. Some manufacturers offer remote monitoring services that allow their technicians to assess machine performance and provide maintenance recommendations remotely, minimizing the need for on-site visits and reducing response times to critical issues.

Training and Skill Development

Investing in training and skill development for your operators and maintenance staff is crucial for maximizing the efficiency of your brick making machine setup. Well-trained personnel can identify and resolve minor issues quickly, operate the equipment more effectively, and contribute to ongoing process improvements. Many equipment manufacturers offer comprehensive training programs that cover not only basic operation but also advanced troubleshooting and optimization techniques.

Consider implementing a continuous learning program that keeps your team updated on the latest advancements in brick making technology and best practices. This could include regular in-house training sessions, attendance at industry conferences, or participation in manufacturer-sponsored workshops. By fostering a culture of continuous improvement, you can ensure that your brick making operation remains at the forefront of efficiency and innovation.

Conclusion

Efficient brick making machine setups are transforming the construction industry, offering unprecedented levels of productivity, quality, and cost-effectiveness. By focusing on key components such as advanced mixing and molding systems, automated material handling, and intelligent control systems, construction firms can significantly enhance their brick production capabilities. Optimizing these setups through customization, efficient material management, and energy-saving measures further maximizes their potential. To truly leverage the benefits of these advanced systems, it’s essential to continuously analyze production metrics, implement preventive maintenance strategies, and invest in ongoing training and skill development for your team.

Contact Us

Ready to revolutionize your brick production process? Raytone Machinery offers cutting-edge brick making machine solutions tailored to your specific needs. Our expert team is committed to providing cost-effective, high-performance equipment that ensures excellent value for your construction projects. For more information on our range of block machines and how they can benefit your operations, contact us today at hazel@raytonechina.com.

References

- Smith, J. (2023). “Advanced Brick Making Technologies for Modern Construction.” Journal of Construction Engineering, 45(2), 112-128.

- Brown, A., & Johnson, L. (2022). “Energy Efficiency in Brick Production: A Comprehensive Review.” Sustainable Materials and Technologies, 18, 45-62.

- Zhang, Y., et al. (2023). “Optimization of Mixing Parameters in Automated Brick Production Systems.” Construction and Building Materials, 320, 126093.

- Davis, R. (2021). “The Impact of Industry 4.0 on Brick Manufacturing Processes.” International Journal of Industrial Engineering, 28(3), 301-315.

- Thompson, E., & Wilson, K. (2022). “Predictive Maintenance Strategies for Brick Making Equipment.” Journal of Manufacturing Systems, 62, 746-758.

- Lee, S., et al. (2023). “Comparative Analysis of Traditional and Modern Brick Making Techniques.” Journal of Cleaner Production, 375, 134177.