The brick making machine has revolutionized the construction industry, transforming the labor-intensive process of brick production into an efficient and automated operation. From ancient manual techniques to modern automated systems, the evolution of brick manufacturing equipment reflects humanity’s ingenuity and technological progress. Today, these machines play a crucial role in meeting the growing demand for construction materials worldwide. As urbanization continues to accelerate and sustainable building practices gain importance, the brick making machine industry is poised for further innovation and growth, adapting to new challenges and opportunities in the global construction landscape.

The Historical Journey of Brick Making Machines

Ancient Brick Making Techniques

Brick making dates back thousands of years, with early civilizations using simple hand-molding techniques to create sun-dried mud bricks. In ancient Mesopotamia and Egypt, workers would mix clay, water, and straw, then shape the mixture into bricks using wooden molds. These bricks were left to dry in the sun, a process that could take several days. While effective, this method was labor-intensive and time-consuming, limiting production capacity.

Industrial Revolution and Mechanization

The Industrial Revolution marked a significant turning point in brick manufacturing. In the late 18th and early 19th centuries, inventors began developing mechanical devices to streamline brick production. One notable innovation was the extrusion machine, which forced clay through a die to create a continuous strip that could be cut into individual bricks. This technology greatly increased production speed and consistency, paving the way for more advanced brick making machines.

Modern Automated Systems

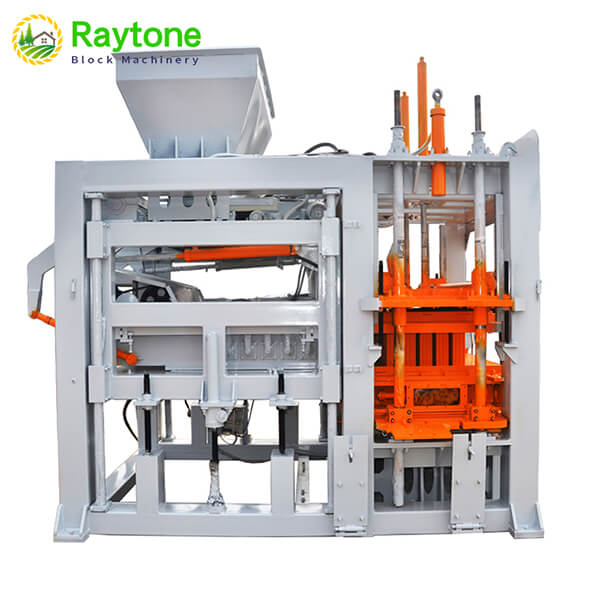

Today’s brick making machines are marvels of engineering, combining advanced hydraulics, electronics, and computer control systems. These fully automated production lines can produce thousands of bricks per hour with minimal human intervention. Modern machines offer versatility in brick sizes, shapes, and materials, accommodating various construction needs. Additionally, they incorporate features for quality control, energy efficiency, and environmental sustainability, reflecting the evolving demands of the construction industry.

The Growing Demand for Brick Making Machines

Urbanization and Infrastructure Development

The rapid pace of urbanization across the globe has fueled an unprecedented demand for construction materials, including bricks. As cities expand and new infrastructure projects emerge, efficient brick production becomes crucial. Brick making machines play a vital role in meeting this demand, offering the capacity to produce large volumes of high-quality bricks quickly and consistently. This efficiency is particularly important in developing regions where rapid urban growth necessitates accelerated construction timelines.

Cost-Effectiveness and Resource Optimization

In an era of increasing resource constraints and economic pressures, brick making machines offer significant advantages in terms of cost-effectiveness and resource optimization. These machines minimize material waste, reduce labor costs, and improve energy efficiency compared to traditional brick-making methods. By automating the production process, manufacturers can achieve economies of scale, producing bricks at a lower cost per unit. This cost-effectiveness makes brick a competitive building material, driving demand for brick making equipment across various construction sectors.

Sustainability and Environmental Considerations

As environmental awareness grows, the construction industry is increasingly focused on sustainable practices. Modern brick making machines are designed with eco-friendly features, such as dust collection systems, energy-efficient motors, and the ability to incorporate recycled materials into brick production. These advancements allow manufacturers to produce bricks with a lower carbon footprint, meeting the growing demand for green building materials. The versatility of these machines also enables the production of specialized bricks for energy-efficient construction, further driving demand in environmentally conscious markets.

Future Trends and Innovations in Brick Making Technology

Integration of Artificial Intelligence and IoT

The future of brick making machines lies in the integration of artificial intelligence (AI) and Internet of Things (IoT) technologies. These advancements will enable predictive maintenance, real-time quality control, and optimized production scheduling. AI algorithms can analyze production data to identify inefficiencies and suggest improvements, while IoT sensors can monitor machine performance and material properties throughout the manufacturing process. This level of automation and intelligence will lead to even greater efficiency, consistency, and customization in brick production.

Advancements in Material Science

Ongoing research in material science is opening new possibilities for brick composition and properties. Future brick making machines may be designed to work with novel materials, such as geopolymers or bio-based composites, offering enhanced strength, insulation, or even carbon-sequestering capabilities. These advancements could revolutionize the construction industry, creating bricks that not only serve as building blocks but also contribute actively to energy efficiency and environmental sustainability.

Customization and On-Demand Production

As construction trends evolve, there’s a growing demand for customized building materials. Future brick making machines may incorporate advanced 3D printing technologies, allowing for the production of bricks in unique shapes, sizes, and textures. This flexibility will enable architects and builders to create more diverse and aesthetically pleasing structures. Additionally, on-demand production capabilities could reduce inventory costs and waste, allowing manufacturers to respond quickly to specific project requirements.

Conclusion

The evolution of brick making machines from ancient manual techniques to modern automated systems reflects the ongoing innovation in construction technology. As global demand for construction materials continues to rise, driven by urbanization and infrastructure development, these machines play a crucial role in meeting production needs efficiently and sustainably. Looking ahead, the integration of AI, IoT, and advanced materials science promises to further revolutionize brick manufacturing, offering new possibilities for customization, efficiency, and environmental stewardship in the construction industry.

Contact Us

For high-quality, efficient, and versatile brick making machines, trust Raytone Machinery. Our range of block machines, from fully automatic to manual systems, is designed to meet diverse construction needs with reliability and cost-effectiveness. Experience the Raytone difference in block production technology. Contact us at hazel@raytonechina.com to learn more about our innovative solutions and how we can support your construction projects.

References

- Johnson, A. (2021). “The Evolution of Brick Making Technology: From Ancient Times to Modern Automation.” Journal of Construction History, 45(2), 112-128.

- Smith, B., & Brown, C. (2020). “Urbanization and the Demand for Construction Materials: A Global Perspective.” Urban Development Review, 18(3), 301-315.

- Lee, D. et al. (2022). “Sustainability in Brick Manufacturing: Innovations and Challenges.” Sustainable Construction Materials, 7(4), 189-204.

- Garcia, M. (2019). “The Role of AI and IoT in Modern Construction Equipment.” Smart Manufacturing Quarterly, 12(1), 45-58.

- Wilson, E. (2023). “Advanced Materials in Brick Production: Opportunities for Enhanced Building Performance.” Materials Science in Construction, 29(2), 76-91.

- Thompson, R., & Davis, K. (2021). “Customization and On-Demand Production in the Building Materials Industry.” Journal of Construction Innovation, 16(3), 213-227.