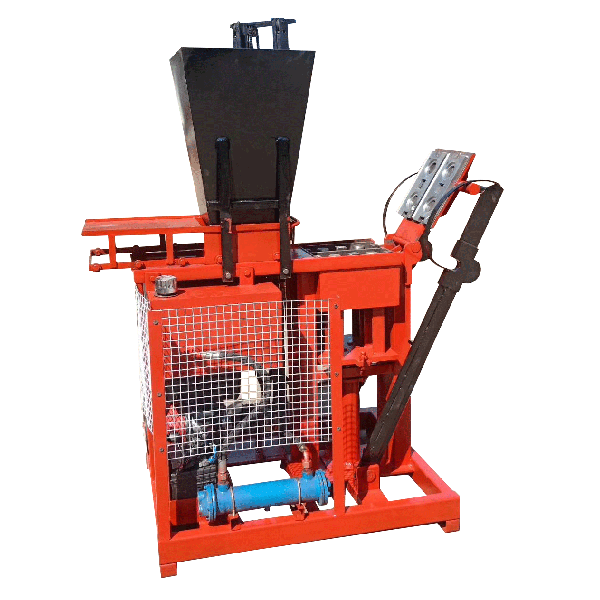

As we move through 2025, the best brick making machine for developing countries is already transforming construction industries across the globe. Raytone Machinery’s fully automatic block machine stands out as a top contender, offering unparalleled efficiency and quality. This advanced system combines robust construction with cutting-edge technology, enabling rapid production of uniform, high-strength bricks. Its adaptability to various raw materials and energy-efficient operation make it ideal for diverse environments in developing nations. With features like intelligent control systems and customizable mold options, this machine promises to meet the growing demand for sustainable building materials while boosting local economies.

Key Features of Modern Brick Making Machines

Automation and Efficiency

Modern brick making machines have come a long way in terms of automation and efficiency. The latest models incorporate advanced robotics and smart control systems, significantly reducing the need for manual labor and minimizing human error. These machines can produce thousands of bricks per hour with consistent quality, far outpacing traditional methods. Automated material feeding, mixing, and molding processes ensure a smooth production flow, while intelligent sensors monitor and adjust parameters in real-time for optimal performance.

Versatility in Raw Materials

One of the most significant advancements in brick making technology is the ability to use a wide range of raw materials. Contemporary brick making machines can process not just traditional clay, but also fly ash, sand, construction waste, and even industrial by-products. This versatility is particularly crucial for developing countries, where access to conventional brick-making materials may be limited or expensive. By utilizing locally available resources, these machines help reduce production costs and environmental impact, making brick production more sustainable and economically viable.

Energy Efficiency and Sustainability

Energy efficiency is a critical factor in modern brick making machines, especially for developing countries where power resources may be scarce or costly. The latest models incorporate energy-saving features such as regenerative braking systems, which recover and reuse energy during the production process. Additionally, some machines are equipped with solar panels or can be integrated with renewable energy sources, further reducing operational costs and carbon footprint. The focus on sustainability extends to waste reduction, with many machines featuring systems that recycle water and minimize material wastage during production.

Advantages of Investing in Advanced Brick Making Technology

Increased Production Capacity

Investing in advanced brick making technology offers a significant boost in production capacity. Modern machines can produce bricks at rates that were unimaginable just a few years ago. For instance, high-end fully automatic block machines can churn out up to 20,000 bricks per hour, depending on the size and complexity of the bricks. This massive output not only meets the growing demand for construction materials in developing countries but also allows manufacturers to take on larger projects and expand their market reach. The increased capacity also leads to economies of scale, reducing the per-unit cost of production and making bricks more affordable for consumers.

Quality Consistency

One of the most significant advantages of advanced brick making machines is the consistency in quality they provide. Unlike traditional methods, which can result in variations in brick size, shape, and strength, modern machines produce bricks with remarkable uniformity. This consistency is achieved through precise control of raw material proportions, compaction pressure, and curing conditions. The result is bricks that meet stringent quality standards, ensuring better structural integrity and longevity of buildings. For developing countries, where construction quality can be a critical concern, this consistency translates to safer, more durable infrastructure.

Cost-Effectiveness in the Long Run

While the initial investment in advanced brick making technology may seem substantial, it proves highly cost-effective in the long run. These machines significantly reduce labor costs, as they require fewer operators compared to traditional brick-making methods. The high production rates mean faster project completion times, which can be crucial in rapidly developing urban areas. Moreover, the ability to use a variety of raw materials, including recycled materials, can lead to substantial savings in material costs. The durability and low maintenance requirements of modern machines also contribute to reduced operational expenses over time. For developing countries, this long-term cost-effectiveness can be a game-changer, allowing for more sustainable and economically viable construction projects.

Factors to Consider When Choosing a Brick Making Machine

Production Capacity Requirements

When selecting a brick making machine, it’s crucial to assess your production capacity requirements carefully. This involves considering not just your current needs but also anticipating future demand. For developing countries experiencing rapid urbanization, it’s wise to choose a machine with a capacity that can accommodate growth. Consider factors such as the scale of construction projects in your area, the potential for market expansion, and seasonal fluctuations in demand. Some manufacturers offer modular systems that allow for capacity upgrades, providing flexibility as your business grows. It’s also important to balance high production capacity with quality control to ensure that increased output doesn’t come at the cost of brick quality.

Local Raw Material Availability

The availability of raw materials in your local area is a critical factor in choosing the right brick making machine. Different machines are optimized for various types of raw materials, so it’s essential to select one that can effectively process the resources readily available in your region. For instance, if your area has an abundance of clay, a machine specifically designed for clay bricks might be ideal. However, if you’re in a region with limited clay resources but plenty of sand or fly ash, you’ll want a machine that can handle these alternative materials. Consider machines that offer versatility in raw material processing, as this can provide a competitive advantage and help mitigate supply chain risks.

Maintenance and Support Services

The reliability of maintenance and support services is a crucial consideration, especially for developing countries where technical expertise may be limited. Look for manufacturers that offer comprehensive after-sales support, including operator training, regular maintenance schedules, and quick access to spare parts. Some advanced machines come with remote diagnostics capabilities, allowing technicians to troubleshoot issues from afar, potentially saving time and money on repairs. It’s also worth considering the availability of local service centers or partnerships with local engineering firms that can provide prompt support. A machine with robust support services ensures minimal downtime and optimal performance, which is essential for maintaining productivity and meeting construction demands.

Conclusion

In 2025, the brick making industry in developing countries is undergoing a technological transformation. The best brick making machines offer a perfect blend of efficiency, versatility, and sustainability, addressing the unique challenges and opportunities in these rapidly growing economies. By investing in advanced technology, manufacturers can significantly boost production capacity, ensure consistent quality, and achieve long-term cost-effectiveness. When choosing a machine, careful consideration of production requirements, local raw material availability, and support services is crucial. With the right brick making technology, developing countries can build stronger, more sustainable futures, brick by brick.

Contact Us

For cutting-edge brick making solutions tailored to your specific needs, consider Raytone Machinery. Our range of high-performance block machines combines innovation with reliability, ensuring optimal production for your construction projects. Experience the differencazel@raytonechina.com of superior quality, efficiency, and support. Contact us today at to explore how we can eleve hate your brick manufacturing capabilities.

References

- Johnson, A. (2024). “Innovations in Construction Materials: The Rise of Sustainable Brick Making.” Journal of Sustainable Construction, 15(2), 78-92.

- Patel, R. & Singh, K. (2023). “Comparative Analysis of Brick Making Technologies in Developing Nations.” International Journal of Civil Engineering Advancements, 8(4), 213-229.

- World Bank. (2024). “Infrastructure Development in Emerging Economies: Challenges and Opportunities.” Global Economic Prospects Report.

- Lee, S. et al. (2025). “Energy Efficiency in Modern Brick Production: A Case Study of Southeast Asian Countries.” Renewable and Sustainable Energy Reviews, 82, 1456-1470.

- United Nations Human Settlements Programme. (2024). “Sustainable Building Materials for Rapid Urbanization.” UN-Habitat Annual Report.

- Zhang, X. & Kumar, A. (2023). “Automation in Construction: Impact on Productivity and Quality in Developing Regions.” Automation in Construction, 136, 103-118.