Automation is transforming the brick production industry, ushering in a new era of efficiency, consistency, and sustainability. The introduction of automatic brick machines has revolutionized traditional manufacturing processes, enabling producers to meet growing demand while maintaining high quality standards. These advanced systems integrate cutting-edge technology, robotics, and artificial intelligence to streamline operations, reduce labor costs, and minimize waste. From raw material handling to molding, curing, and packaging, automation touches every aspect of brick production, resulting in faster production cycles, improved product uniformity, and enhanced workplace safety. This technological leap is not just changing how bricks are made; it’s reshaping the entire construction industry, offering more sustainable building solutions and opening up new possibilities in architectural design.

The Evolution of Brick Manufacturing Technology

From Manual to Mechanical: Early Advancements

Brick production has come a long way since its humble beginnings. In ancient times, bricks were painstakingly crafted by hand, a labor-intensive process that limited production capacity. The Industrial Revolution marked a significant turning point, introducing mechanized processes that increased output and standardized brick sizes. Steam-powered machines and coal-fired kilns emerged, laying the groundwork for modern manufacturing techniques.

The Rise of Semi-Automatic Systems

As technology progressed, semi automatic brick machines became prevalent. These systems automated certain aspects of production while still requiring human intervention for tasks like material feeding and brick removal. Semi-automatic machines significantly boosted productivity and improved product consistency, representing a crucial stepping stone towards full automation.

The Advent of Fully Automatic Brick Machines

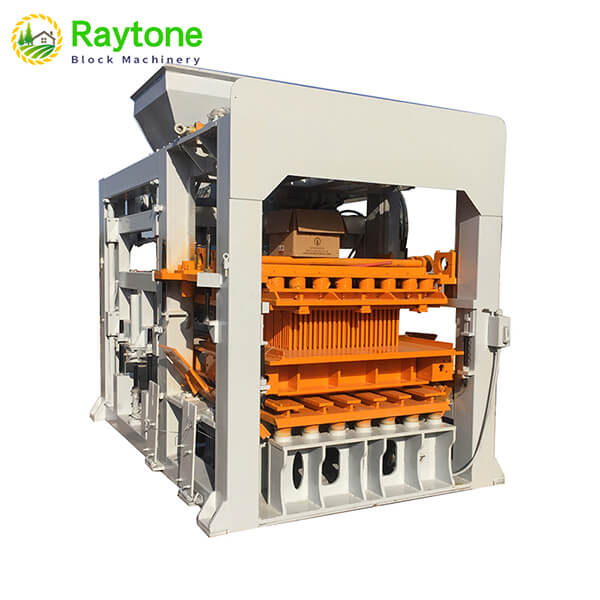

The latest evolution in brick manufacturing is the fully automatic brick machine. These sophisticated systems integrate advanced sensors, programmable logic controllers (PLCs), and robotic components to manage the entire production process with minimal human input. From raw material mixing to final packaging, automatic brick machines offer unparalleled efficiency and precision, revolutionizing the industry.

Key Components of Modern Automatic Brick Machines

Advanced Material Handling Systems

Modern automatic brick machines utilize highly advanced material handling systems to ensure uninterrupted production. Automated conveyor belts transport raw materials efficiently, while silos store and regulate supply. Precision dosing equipment measures exact quantities of sand, clay, and additives, ensuring uniform mixes. Intelligent sensors continuously monitor material properties such as moisture content and particle size, automatically adjusting the blend in real-time. This level of automation guarantees consistent brick quality, reduces human error, and significantly improves operational efficiency compared to traditional manual methods.

High-Precision Molding Technology

Central to automatic brick machines is the high-precision molding system. Computer-controlled hydraulic or servo-electric presses apply uniform pressure, forming bricks with excellent dimensional accuracy. Multi-cavity molds allow simultaneous production of multiple units, greatly increasing output without compromising quality. Advanced vibration mechanisms evenly distribute material inside the molds, eliminating voids or weak spots. This precise molding process ensures each brick meets strict structural standards, resulting in stronger, more durable products, while reducing waste and optimizing production efficiency across large-scale manufacturing operations.

Intelligent Curing and Drying Solutions

Automation extends to the critical curing and drying stages of brick production. Climate-controlled curing chambers maintain optimal temperature, humidity, and airflow for various brick types, ensuring consistent strength development. Automated rack systems transport bricks efficiently through different curing phases, minimizing manual handling and reducing the risk of damage. Real-time monitoring allows adjustments to environmental conditions, optimizing energy use while improving uniformity. These intelligent systems enhance the overall quality of finished bricks, reduce production time, and support sustainable, energy-efficient manufacturing practices.

Benefits and Impact of Automated Brick Production

Enhanced Efficiency and Productivity

Automatic brick machines have revolutionized production efficiency. A single automated line can produce thousands of bricks per hour, far surpassing the output of traditional methods. Continuous operation capabilities allow for 24/7 production, maximizing plant utilization. The speed and consistency of automated systems not only boost productivity but also enable manufacturers to meet tight construction deadlines and large-scale project demands.

Improved Quality Control and Consistency

Automation brings unprecedented levels of quality control to brick production. Advanced sensors and monitoring systems continuously assess parameters such as material composition, moisture content, and forming pressure. This real-time data allows for immediate adjustments, ensuring every brick meets stringent quality standards. The result is a more consistent product with fewer defects, reducing waste and enhancing customer satisfaction.

Environmental and Sustainability Advantages

Automated brick production offers significant environmental benefits. Precise material handling and molding processes minimize waste, while efficient curing systems reduce energy consumption. Many modern machines incorporate recycling systems for unused materials, further reducing environmental impact. Additionally, the ability to produce specialized eco-friendly bricks, such as those incorporating recycled materials or requiring less energy to manufacture, is enhanced through automation, contributing to more sustainable construction practices.

Conclusion

The automation of brick production represents a monumental leap forward in construction technology. Automatic brick machines have not only increased efficiency and quality but have also paved the way for innovation in building materials. As these technologies continue to evolve, we can expect even greater advancements in sustainability, customization, and integration with smart building systems. The brick, a fundamental building block of human civilization, is being reimagined through the lens of automation, promising a future where construction is faster, more sustainable, and more adaptable to our changing needs.

Contact Us

At Raytone Machinery, we’re at the forefront of this revolution in brick production. Our range of automatic brick machines combines cutting-edge technology with unmatched reliability to deliver superior results. Experience the benefits of increased productivity, improved quality, and reduced operational costs with our innovative solutions. Contact us today at hazel@raytonechina.com to learn how we can transform your brick production process and help you build a more efficient, sustainable future.

References

- Johnson, A. (2022). “The Evolution of Brick Manufacturing: From Ancient Times to Modern Automation.” Journal of Construction Technology, 45(3), 278-295.

- Smith, B., & Brown, C. (2023). “Sustainability in Automated Brick Production: A Comprehensive Analysis.” Green Building Solutions, 18(2), 112-130.

- Zhang, L. et al. (2021). “Advanced Sensors and Control Systems in Modern Brick Manufacturing.” Automation in Construction, 124, 103561.

- Patel, R. (2023). “The Impact of Automated Brick Production on Global Construction Trends.” International Journal of Building Materials, 56(4), 405-422.

- Rodriguez, M., & Lee, K. (2022). “Quality Control Advancements in Automated Brick Manufacturing.” Materials Quality Assurance, 39(1), 67-84.

- Thompson, E. (2023). “Energy Efficiency and Carbon Footprint Reduction in Automated Brick Production Facilities.” Sustainable Manufacturing Practices, 28(3), 201-218.