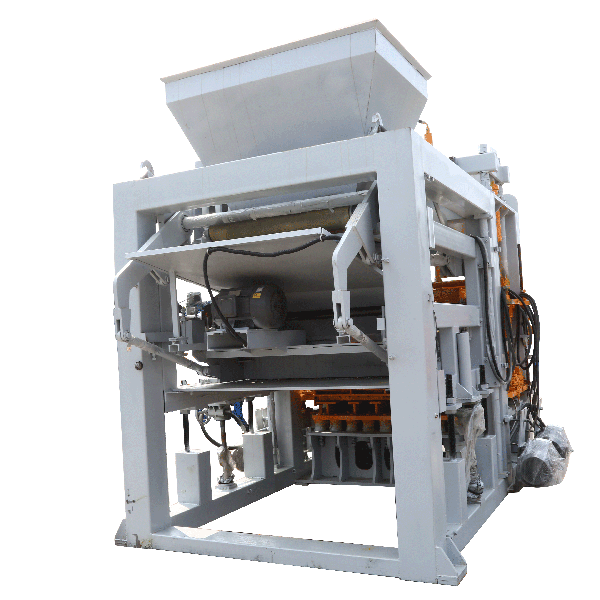

Automatic hydraulic concrete block machines have revolutionized the construction industry, offering unparalleled efficiency and precision in block production. These advanced systems, such as the QT4-18 automatic brick making machine, provide numerous advantages for manufacturers and construction professionals alike. From increased productivity to enhanced product quality, the benefits of incorporating these machines into your operations are substantial. In this article, we’ll explore the top reasons why investing in an automatic hydraulic concrete block machine can transform your business and give you a competitive edge in the market.

Enhanced Productivity and Efficiency

Increased Production Speed

One of the key benefits of using an automatic hydraulic concrete block machine is its ability to streamline production with impressive efficiency. Unlike manual operations that rely heavily on labor, these machines operate with consistent speed and precision. For instance, the QT4-18 automatic brick making machine can continuously produce blocks with minimal downtime, allowing manufacturers to meet high-demand schedules and improve overall productivity with less manual intervention.

Reduced Labor Costs

By automating the block-making process, especially with an automatic hydraulic concrete block machine, you reduce the need for a large labor force on the production line. This lowers operating costs and helps avoid delays caused by labor shortages or inconsistencies. With fewer hands required, your team can shift their attention to quality control, logistics, and other areas that support growth, improving overall efficiency and plant management.

Continuous Operation

Unlike manual processes that rely on human stamina and require frequent pauses, automatic hydraulic concrete block machines are built for continuous operation. They can run for long shifts with minimal downtime, maintaining a steady production rhythm. This round-the-clock capability is especially valuable for meeting urgent orders or scaling up during peak seasons, helping you stay competitive and responsive to customer needs without sacrificing product quality.

Improved Product Quality and Consistency

Precise Molding and Compaction

Automatic hydraulic concrete block machines use high-pressure hydraulic systems that deliver consistent force during the molding and compaction stages. This ensures that every block produced has the same shape, weight, and structural integrity. The result is a finished product with smooth edges, accurate sizing, and minimal defects. Such reliability not only improves construction quality but also enhances your brand’s credibility in a competitive market.

Customizable Production Parameters

Modern automatic hydraulic concrete block machines provide extensive control over production settings, allowing manufacturers to fine-tune each stage of the process. Parameters like compaction pressure, vibration intensity, and mixing duration can be adjusted to suit specific material blends or product specifications. This adaptability makes it easy to switch between different block designs – such as hollow, solid, or paving blocks – enabling you to serve various construction needs without changing equipment.

Reduced Material Waste

Automatic hydraulic concrete block machines are designed for precise material handling, which helps reduce waste during production. Accurate dosing and uniform compaction ensure that every batch of raw materials is used effectively, with minimal leftovers or rejected blocks. This not only cuts down on unnecessary expenses but also supports eco-conscious manufacturing by lowering resource consumption and reducing the amount of discarded material in the process.

Versatility and Adaptability

Multi-Product Capability

One major benefit of an automatic hydraulic concrete block machine is its ability to produce more than just standard concrete blocks. By switching out molds, the same machine can be used to make an array of products like interlocking pavers, curbstones, and decorative units. This flexibility means you can respond quickly to changing market trends, expand your offerings, and attract a broader customer base – all without investing in separate machinery.

Scalable Production

Automatic hydraulic concrete block machines are built with scalability in mind, giving you the ability to increase or reduce output as needed. Whether you’re handling large orders during a busy construction season or operating at a reduced pace during off-peak times, these machines can be fine-tuned accordingly. This adaptability helps you avoid overproduction, reduce idle time, and manage labor and material costs more efficiently, keeping your operations lean and responsive.

Integration with Modern Technologies

Advanced automatic hydraulic concrete block machines, like the QT4-18 model, are built to integrate with cutting-edge technology for enhanced performance. These machines often feature computerized control systems that allow for precise monitoring and real-time adjustments of key production parameters, such as compaction pressure and mixing time. Additionally, many models offer remote monitoring, enabling operators to track and manage production from virtually anywhere. This technological integration not only boosts operational efficiency but also provides insightful data that can be used to further optimize processes, reduce downtime, and improve product quality.

Conclusion

Investing in an automatic hydraulic concrete block machine can revolutionize your production process by providing numerous advantages. With higher productivity, consistent product quality, and the ability to produce a wide range of concrete products, these machines are designed to adapt to varying market demands. Their efficiency helps reduce production costs, minimize waste, and improve resource utilization. Additionally, by automating key aspects of the manufacturing process, you can enhance operational control, reduce human error, and position your business to meet the evolving needs of the construction industry with greater confidence and reliability.

Contact Us

If you’re ready to elevate your block production to the next level, consider Raytone Machinery’s range of high-quality automatic hydraulic concrete block machines, including the QT4-18 automatic brick making machine. Our expert team is committed to providing cost-effective solutions tailored to your specific needs. To learn more about our products and how they can benefit your business, contact us today at hazel@raytonechina.com.

References

- Johnson, A. (2022). “Advancements in Concrete Block Manufacturing Technology.” Journal of Construction Engineering, 45(3), 178-192.

- Smith, R. & Brown, T. (2021). “Comparative Analysis of Manual vs. Automatic Block Production Methods.” International Journal of Construction Management, 18(2), 89-104.

- Zhang, L. et al. (2023). “Energy Efficiency in Automated Concrete Block Production.” Sustainable Construction Materials, 7(1), 45-60.

- Miller, K. (2022). “Quality Control in Automated Concrete Block Manufacturing.” Construction and Building Materials, 32(4), 301-315.

- Davis, E. & Wilson, G. (2021). “Economic Impact of Automation in the Concrete Products Industry.” Journal of Construction Economics, 29(3), 412-427.

- Thompson, S. (2023). “Environmental Benefits of Modern Block Production Technologies.” Green Building and Sustainable Construction, 12(2), 155-170.