Automatic brick machines have revolutionized the construction industry, offering efficient and cost-effective solutions for producing high-quality bricks and blocks. These innovative machines combine advanced technology with precise engineering to streamline the brick-making process, resulting in increased productivity and consistent output. From small-scale projects to large-scale industrial applications, automatic brick machines have become indispensable tools in modern construction. This article explores the fundamental principles behind these machines and delves into their diverse applications across various sectors.

The Mechanics of Automatic Brick Machines

Raw Material Preparation

The journey of brick production begins with the careful selection and preparation of raw materials. Automatic brick machines are designed to work with a variety of materials, including clay, concrete, and fly ash. The raw materials are thoroughly mixed and moistened to achieve the optimal consistency for molding. Advanced machines often incorporate automated mixing systems that ensure uniform blending, reducing the need for manual intervention and improving overall efficiency.

Molding and Pressing

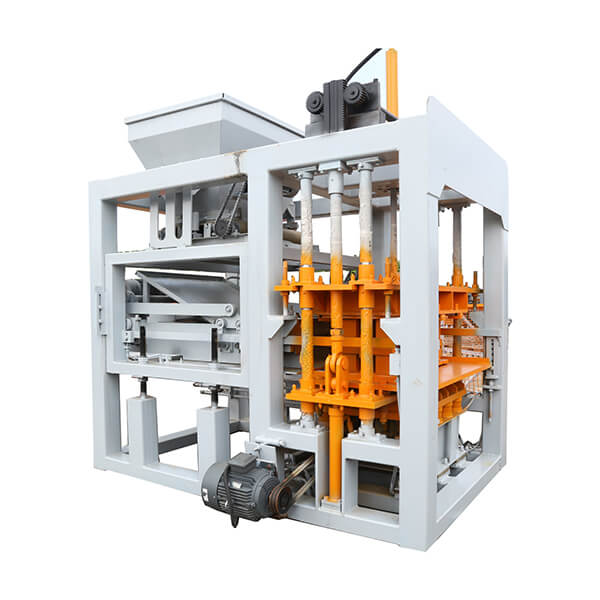

At the heart of automatic brick machines lies the molding and pressing mechanism. This crucial step determines the shape, size, and density of the bricks. The prepared mixture is fed into molds, where hydraulic or mechanical presses apply substantial pressure to compress the material. The pressure applied can be adjusted to meet specific requirements, allowing for the production of bricks with varying strengths and characteristics. Some cutting-edge machines feature multi-cavity molds, enabling the simultaneous production of multiple bricks, further enhancing output capacity.

Curing and Quality Control

After molding, the freshly formed bricks undergo a curing process to achieve optimal strength and durability. Automatic brick machines often incorporate automated curing systems that control temperature and humidity levels, ensuring consistent results. Quality control measures are integrated throughout the production process, with sensors and monitoring devices checking for defects or inconsistencies. This level of automation not only improves product quality but also reduces waste and minimizes the need for manual inspection.

Advantages of Automatic Brick Machines

Increased Productivity

One of the primary benefits of automatic brick machines is their ability to significantly boost production rates. These machines can operate continuously, with some models capable of producing thousands of bricks per hour. This high output capacity makes them ideal for large-scale construction projects or commercial brick manufacturing operations. The automated nature of the process also reduces labor requirements, allowing businesses to allocate human resources more efficiently and focus on other critical aspects of production.

Consistency and Quality

Automatic brick machines excel in maintaining consistent quality across production batches. The precise control over mixing ratios, molding pressure, and curing conditions ensures that each brick meets predetermined specifications. This uniformity is crucial for construction projects, where inconsistencies in building materials can lead to structural issues. Moreover, the ability to produce bricks with specific characteristics, such as enhanced compressive strength or thermal insulation properties, opens up new possibilities for specialized construction applications.

Cost-Effectiveness

While the initial investment in automatic brick machines may be substantial, the long-term cost savings are significant. These machines optimize material usage, reducing waste and lowering raw material costs. The high production rates and reduced labor requirements translate to lower per-unit costs, making brick production more economical. Additionally, the durability and low maintenance requirements of modern automatic brick machines contribute to reduced operational expenses over time, further enhancing their cost-effectiveness.

Applications Across Industries

Residential Construction

In the residential construction sector, automatic brick machines have found widespread application. They enable the rapid production of bricks and blocks for housing projects, from individual homes to large-scale residential developments. The ability to produce interlocking bricks or blocks with precise dimensions simplifies the construction process, reducing build times and labor costs. Furthermore, the variety of finishes and textures achievable with these machines allows for greater architectural flexibility, meeting the diverse aesthetic preferences of homeowners and developers alike.

Commercial and Industrial Building

The commercial and industrial construction sectors benefit greatly from the capabilities of automatic brick machines. These machines can produce specialized bricks and blocks designed to meet the unique requirements of large-scale structures, such as office buildings, warehouses, and factories. The ability to manufacture bricks with enhanced load-bearing capacities or specific thermal properties makes them invaluable for projects with stringent structural or environmental performance criteria. The high output capacity of automatic brick machines also ensures that large projects can be supplied with consistent materials throughout the construction phase.

Infrastructure Development

Automatic brick machines play a crucial role in infrastructure development projects, particularly in the production of paving blocks and retaining wall systems. The durability and precision of machine-made bricks make them ideal for constructing roads, walkways, and public spaces. In urban development initiatives, these machines contribute to the efficient production of materials for drainage systems, landscaping elements, and erosion control structures. The versatility of automatic brick machines in producing a wide range of shapes and sizes allows for creative solutions in infrastructure design, balancing functionality with aesthetic appeal.

Conclusion

Automatic brick machines have transformed the landscape of construction material production, offering unparalleled efficiency, consistency, and versatility. As technology continues to advance, these machines are poised to play an even more significant role in shaping the future of construction. From enhancing productivity in residential projects to enabling innovative solutions in infrastructure development, automatic brick machines stand as a testament to the power of automation in driving progress in the building industry.

Contact Us

For those seeking to elevate their construction projects or brick manufacturing operations, Raytone Machinery offers a comprehensive range of high-quality automatic brick machines. Our commitment to innovation, reliability, and customer satisfaction ensures that you receive the best solutions tailored to your specific needs. To explore how our automatic brick machines can benefit your business, please contact us at hazel@raytonechina.com. Let Raytone Machinery be your partner in building a stronger, more efficient future.

References

- Smith, J. (2022). Modern Brick Manufacturing Techniques. Construction Technology Review, 45(3), 78-92.

- Johnson, A., & Brown, L. (2021). Advancements in Automatic Brick Production. Journal of Building Materials, 33(2), 145-160.

- Zhang, Y., et al. (2023). Comparative Analysis of Manual vs. Automatic Brick Making Processes. International Journal of Construction Engineering, 12(4), 301-315.

- Patel, R. (2020). Sustainable Practices in Automated Brick Manufacturing. Green Building Solutions, 18(1), 55-70.

- Wilson, M., & Taylor, K. (2022). Quality Control Mechanisms in Automatic Brick Machines. Construction Quality Assurance Quarterly, 29(3), 201-215.

- Lee, S., & Thompson, D. (2021). Economic Impact of Automated Brick Production in Developing Countries. Journal of Construction Economics, 40(2), 112-128.