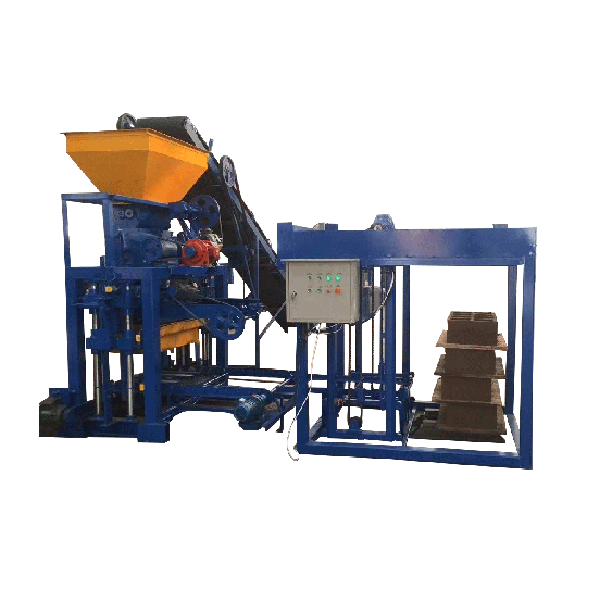

The QT4-35 Manual Brick Making Machine, also known as a Manual Hydraulic Block Forming Machine, is an efficient and economical solution designed for small and medium-sized construction material producers. With a compact structure and reliable performance, this model is widely recognized for its easy operation, low investment, and ability to produce various types of concrete blocks.

Working Principle

The QT4-35 operates through a simple yet effective production process.

First, the operator loads raw materials — typically a mixture of cement, sand, stone powder, and aggregate — into the machine’s hopper. The materials are evenly distributed into the mould box. Then, the operator manually activates the hydraulic pressure system, which compresses and shapes the material inside the mould. Once the compaction is complete, the finished blocks are automatically ejected onto a pallet for curing.

This straightforward workflow makes the QT4-35 a user-friendly and cost-efficient block making machine, perfectly suited for developing markets and local construction projects.

Main Components of the QT4-35 Brick Machine

The QT4-35 manual brick moulding machine is made up of several key systems that work together to ensure stable and efficient block production.

-

Main Frame – Built from high-strength welded steel, providing durability and resistance to vibration during operation.

-

Hopper – The feeding hopper stores and delivers the prepared raw materials into the mould box.

-

Mould Box – Determines the size, shape, and design of the blocks. Moulds can be easily changed to produce different products.

-

Manual Hydraulic System – Provides the necessary compaction force to achieve dense and solid bricks.

-

Vibration Platform – Assists in filling and compacting the material uniformly, improving block surface smoothness and internal density.

-

Brick Ejector and Pallet Feeder – Ensures smooth transfer of finished products from the mould to pallets for curing.

Each component plays a critical role in maintaining consistent product quality and operational efficiency.

Flexible Mould Options

One of the greatest advantages of the QT4-35 machine is its customizable mould design.

With interchangeable moulds, the same machine can produce a wide range of concrete products, including:

-

Hollow blocks

-

Solid bricks

-

Paver bricks

-

Curbstones

This adaptability allows manufacturers to respond quickly to different market demands without investing in multiple machines. Whether producing construction-grade blocks for housing or decorative pavers for landscaping, the QT4-35 can easily meet the production needs of various clients and projects.

Installation and Workspace Setup

The QT4-35 manual brick machine is compact and easy to install, requiring minimal technical expertise.

To achieve maximum productivity, it is recommended to prepare a well-organized workspace:

-

Factory area: about 200 m²

-

Machine operation area: around 40 m²

-

Curing and storage area: approximately 100–150 m²

A stable and level foundation is essential to ensure vibration accuracy and prevent uneven block formation. Additionally, having a dedicated curing zone helps maintain consistent product quality and strength.

Operating Procedure of the QT4-35 Manual Block Machine

1. Material Preparation and Feeding

The production process begins by mixing cement, sand, and stone aggregates in precise ratios to achieve the desired block strength. The well-blended mixture is then manually loaded into the machine’s hopper. Consistent feeding helps maintain smooth and continuous production.

2. Moulding and Compaction

The mixed materials enter the mould cavity, where the operator activates the manual hydraulic pressure. Hydraulic compression and vibration together compact the mixture tightly, forming strong, uniform blocks.

This process allows precise control — operators can adjust the pressure and vibration time to match specific product requirements.

3. Block Ejection and Pallet Handling

After compaction, the formed blocks are ejected automatically onto a pallet. Operators must handle these freshly molded products carefully, as they are still soft before curing. The pallets are then moved to a designated curing area, where the bricks undergo natural air curing or steam curing until they reach full strength.

Production Capacity and Performance

The QT4-35 Manual Brick Machine delivers impressive output for its size and price.

Under standard conditions, it can produce approximately:

-

3290 pieces of 8-inch hollow blocks per 8-hour shift, or

-

10400 pieces of standard solid bricks per shift

With only 4–5 workers, the machine offers high efficiency and stable operation. Its combination of manual control and hydraulic compaction ensures both flexibility and quality in production.

Advantages of the QT4-35 Manual Brick Moulding Machine

1. Low Investment, High Returns

With a typical price range of USD 5,000–15,000, the QT4-35 offers an ideal starting point for small-scale block factories or entrepreneurs entering the construction materials industry. It provides excellent value for money with minimal operational costs.

2. Durable Structure

All components are built from high-quality steel with advanced welding and heat treatment, ensuring long service life and reduced maintenance frequency.

3. Energy Saving and Easy Operation

As a manual hydraulic block machine, it consumes less energy compared to fully automatic models. Its simple control system allows operators to learn and start production quickly.

4. Wide Product Range

By changing moulds, users can produce multiple types of bricks and blocks for different applications — from load-bearing hollow blocks to decorative paving bricks and curbstones.

5. Ideal for Different Environments

The QT4-35 is suitable for both urban and rural construction projects, including local housing, road paving, and small infrastructure works. It’s also widely used in developing regions and humanitarian construction programs where power supply is limited but durable building materials are in demand.

Applications of the QT4-35 Block Machine

This model is widely used in:

-

Residential construction (walls, partition blocks)

-

Public infrastructure projects (roadsides, walkways, parks)

-

Community development projects (schools, clinics, rural housing)

Thanks to its versatility, durability, and easy operation, the QT4-35 continues to be one of the most popular manual block making machines among small contractors and material suppliers.

Conclusion

The QT4-35 Manual Hydraulic Brick Making Machine combines simplicity, efficiency, and flexibility in one compact design. With low investment, low maintenance, and high productivity, it provides an excellent opportunity for small and medium enterprises to start or expand their concrete block manufacturing business.

Whether producing hollow blocks, solid bricks, or paving stones, the QT4-35 ensures reliable quality and consistent output, making it a trusted choice for construction material producers worldwide.

Contact Us

At Raytone Machinery, we specialize in providing complete solutions for brick and block making machines.

Our QT4-35 Manual Block Machine has been successfully exported to over 80 countries, helping clients establish profitable block factories with professional technical support and after-sales service.

📧 Email: hazel@raytonechina.com

Raytone Machinery — Your Reliable Partner for Brick and Block Production.